A kind of sponge city water treatment method

A sponge city, water treatment technology, applied in multi-stage water treatment, water/sewage treatment, water/sewage multi-stage treatment, etc., can solve the problems of inability to realize flood discharge, high treatment cost, low efficiency, etc., to ensure long-term use Effects of stability, high toughness and mechanical strength, low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

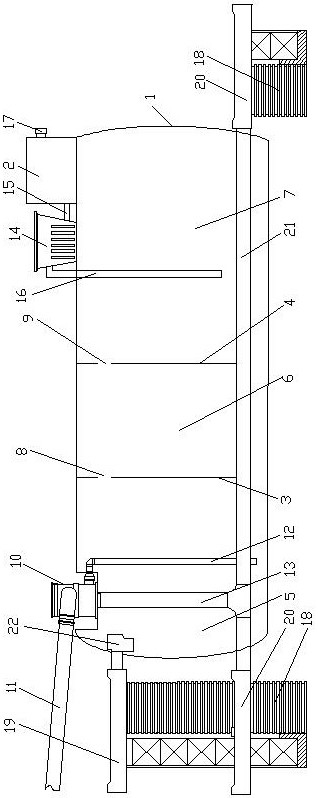

[0048] A kind of sponge city water treatment method, comprises the following steps:

[0049] In the water diversion step, rainwater and sewage are introduced into the sediment separator 10 of the sponge city integrated system;

[0050] In the water treatment step, mud and water are separated through the sediment separator 10, and the separated clean water is introduced into the first water treatment chamber 5, and the clear water after precipitation in the first water treatment chamber 5 enters the second water treatment chamber 6 and the third water treatment chamber in turn. Chamber 7, the water in the third water treatment chamber 7 is purified by water treatment machine 14;

[0051] In the water storage step, the purified water is introduced into the water storage tank 2 and stored for later use;

[0052] In the drainage step, the sewage separated by the sediment separator 10 flows into the flood discharge pipe 21 through the sewage pipe 13, and is discharged through the ...

Embodiment 2

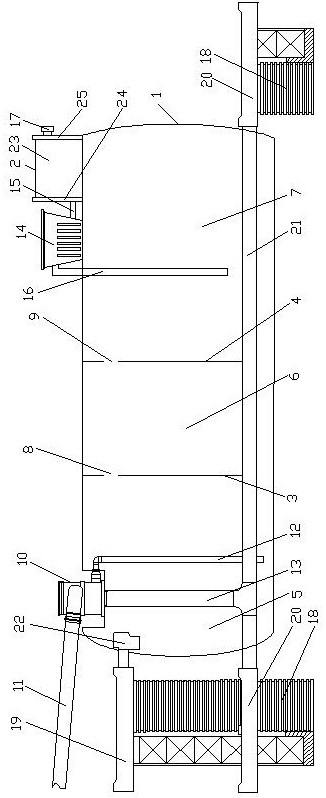

[0056] A kind of sponge city water treatment method, comprises the following steps:

[0057] In the water diversion step, rainwater and sewage are introduced into the sediment separator 10 of the sponge city integrated system;

[0058] In the water treatment step, mud and water are separated through the sediment separator 10, and the separated clean water is introduced into the first water treatment chamber 5, and the clear water after precipitation in the first water treatment chamber 5 enters the second water treatment chamber 6 and the third water treatment chamber in turn. Chamber 7, the water in the third water treatment chamber 7 is purified by water treatment machine 14;

[0059] In the water storage step, the purified water is introduced into the water storage tank 2 and stored for later use;

[0060] In the drainage step, the sewage separated by the sediment separator 10 flows into the flood discharge pipe 21 through the sewage pipe 13, and is discharged through the ...

Embodiment 3

[0065] A kind of sponge city water treatment method, comprises the following steps:

[0066] In the water diversion step, rainwater and sewage are introduced into the sediment separator 10 of the sponge city integrated system;

[0067] In the water treatment step, mud and water are separated through the sediment separator 10, and the separated clean water is introduced into the first water treatment chamber 5, and the clear water after precipitation in the first water treatment chamber 5 enters the second water treatment chamber 6 and the third water treatment chamber in turn. Chamber 7, the water in the third water treatment chamber 7 is purified by water treatment machine 14;

[0068] In the water storage step, the purified water is introduced into the water storage tank 2 and stored for later use;

[0069] In the drainage step, the sewage separated by the sediment separator 10 flows into the flood discharge pipe 21 through the sewage pipe 13, and is discharged through the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com