Novel low-cost and high-performance titanium alloy

A titanium alloy, low-cost technology, applied in high-performance titanium alloys, new low-cost fields, can solve the problems of long processing cycle, high material processing loss, high cost, and achieve good surface deformation ability, high forge deformation ability, and difficult The effect of forging cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

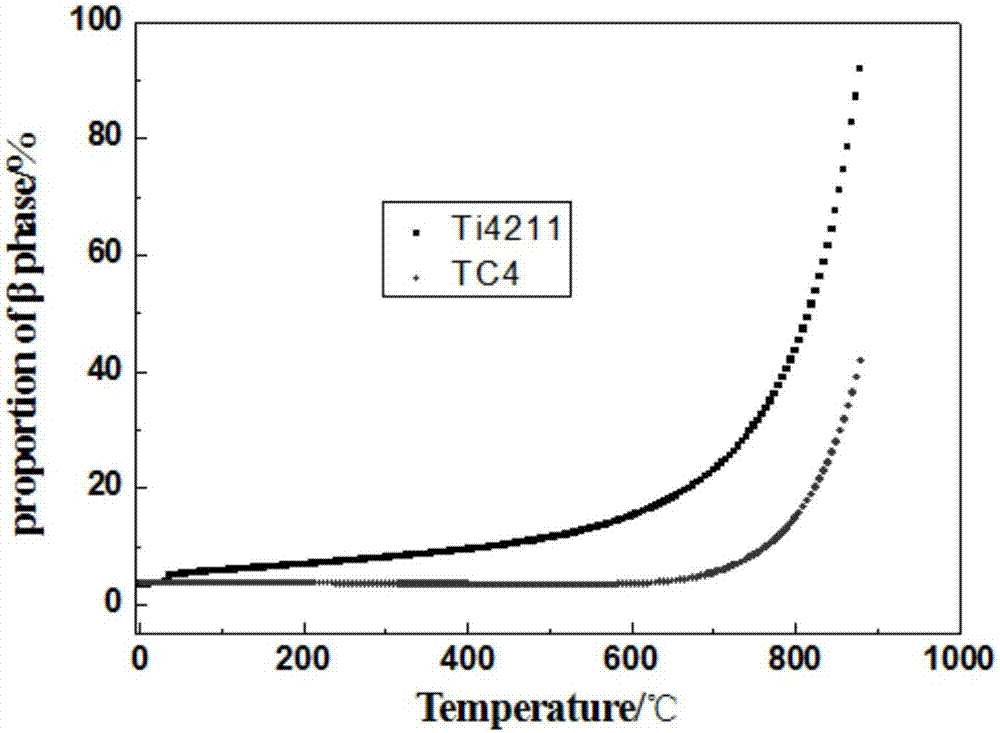

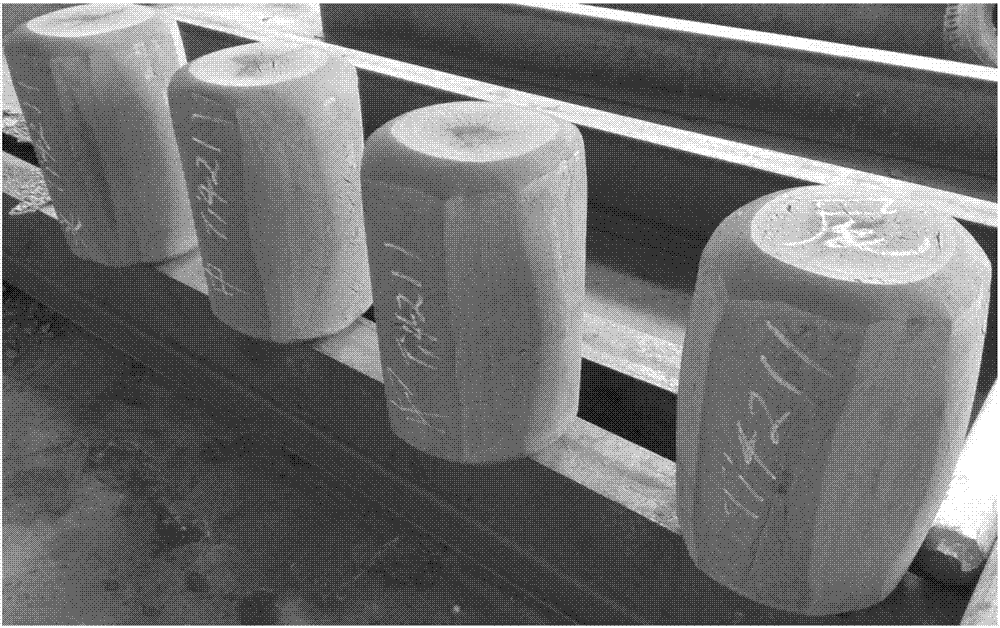

[0047] According to the chemical composition, ingredients were prepared and the smelting electrode was prepared. The low-cost and high-performance titanium alloy was smelted by three vacuum self-consumption methods. The ingot size was 100kg. The three chemical compositions with better comprehensive performance are listed in Table 1. The 1#, 2#, 3# alloys, in which the V element is added through the Al-V master alloy, the Mo element is added through the Al-Mo master alloy, the Al element is added in the form of Al beans, and the Fe element is added in the form of Fe powder. The ingots melted three times under vacuum are forged at 1150°C, and the crystal grains are broken by upsetting at 1050°C, and then forged into a rod with a diameter of 120mm at 880°C in the α+β two-phase region, and finally forged at 880°C through the precision forging process into rods with a diameter of 50mm. The 50mm diameter bar was subjected to three different heat treatments, and the heat treatment sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com