High-temperature high-pressure steam valve sealing face on-site online heat treatment system

A heat treatment system and valve sealing technology, applied in the field of heat treatment systems, can solve the problems of unsatisfied process requirements, time-consuming and labor-intensive problems, and achieve the effects of avoiding the tendency of cracks on the sealing surface and facilitating installation and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

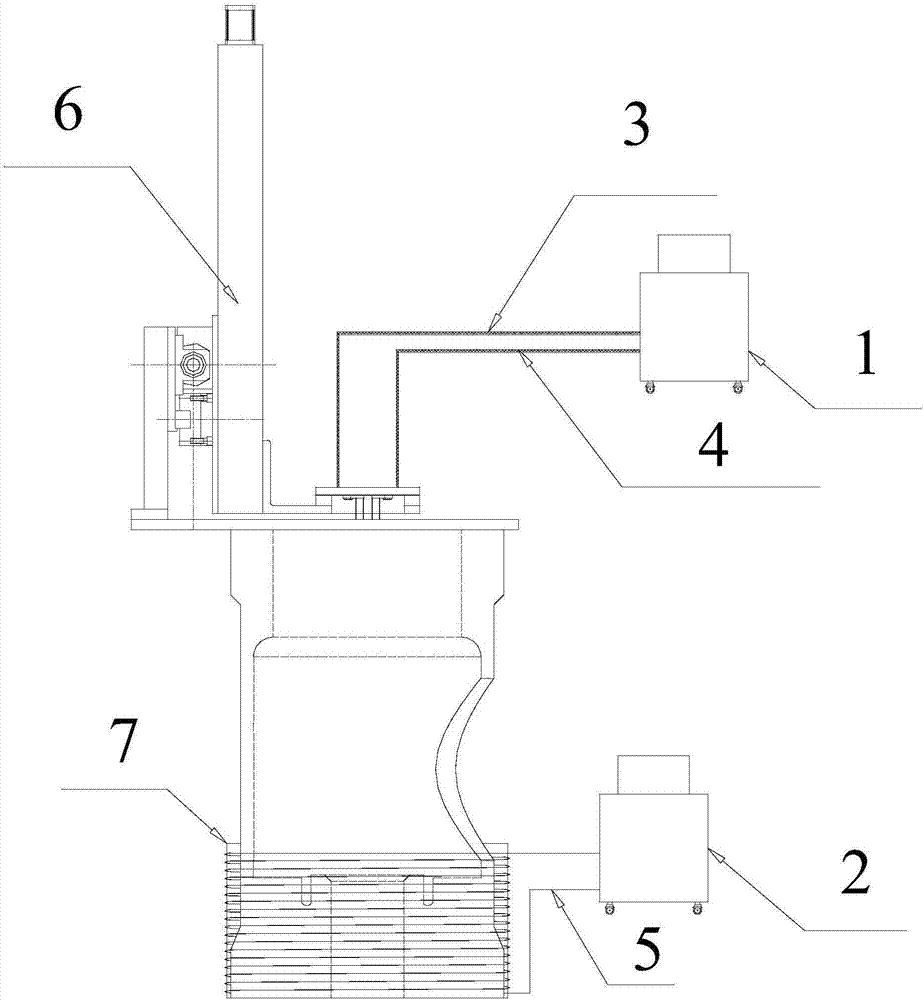

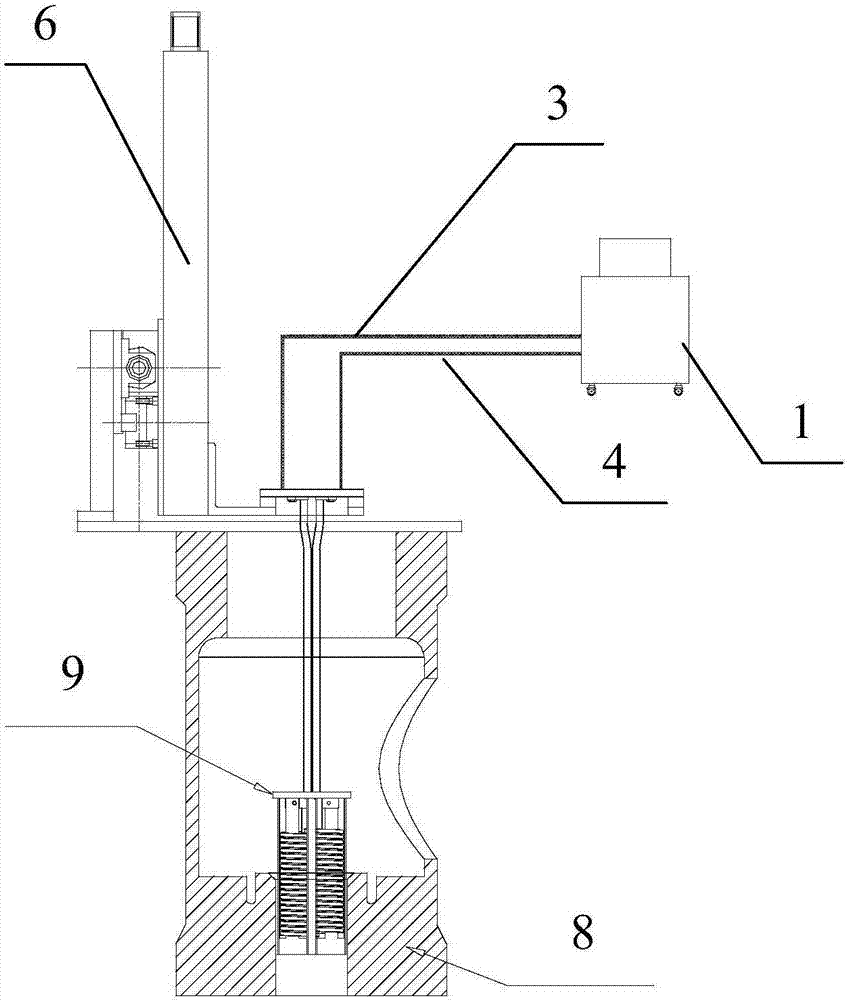

[0022] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

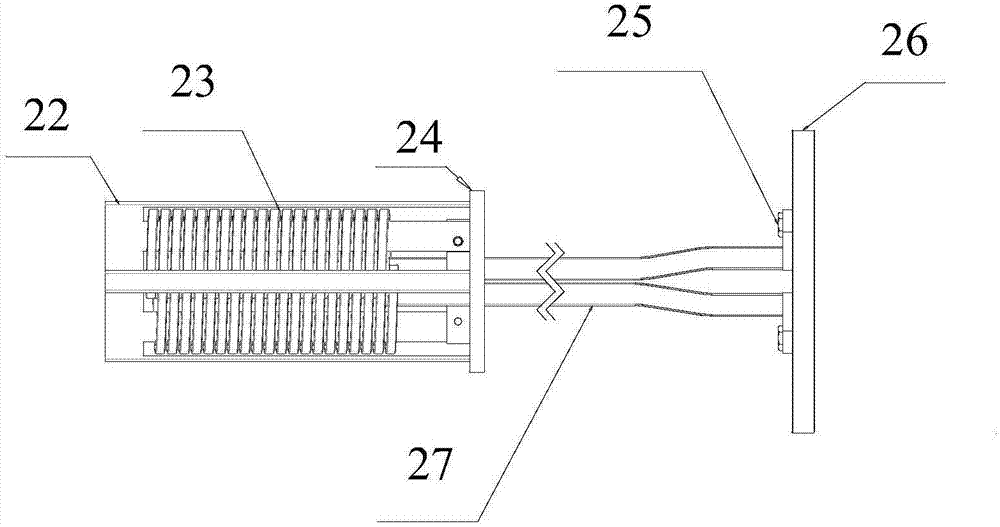

[0023] like Figure 1 to Figure 7 As shown, the on-site on-line heat treatment system for the sealing surface of the high-temperature and high-pressure steam valve of the present invention includes an intermediate frequency induction internal heating power supply 1, an intermediate frequency induction external heating power supply 2, a first water-cooled heating power supply 3, a second water-cooled heating power supply 4, an air-cooled cable 5, and a heat treatment Lifting device 6, insulation cotton 7, valve body 8, induction coil 9, heat treatment lifting device 6 includes stepping motor 10, slide table 11, L-shaped coil fixing flange 12, valve cover end face 13, horizontal moving fixed steel plate 14, Screw fixing nut 15, sliding table positioning block 16, device fixing screw hole 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com