A ceramic wire/cable core manufacturing system

A technology for manufacturing systems and cable cores, applied in cable/conductor manufacturing, circuits, electrical components, etc., can solve problems such as difficult to achieve high-speed production of ceramic wires and cables, and achieve market competitiveness, continuous production, and simple process equipment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

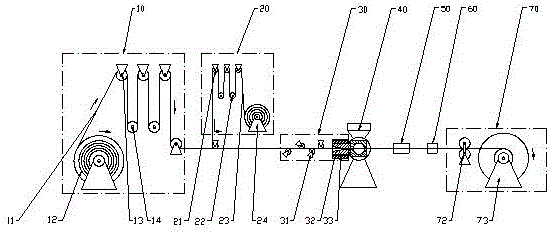

[0041] see figure 1, which discloses the longitudinal wrapping mechanism (embodiment 1) of the ceramic wire / cable core manufacturing system of the present invention, including a series-connected storage and release unit 10, a longitudinal wrapping unit 30, and a set of sheath layer extruding unit 40 , cooling and heating unit 50, high-voltage spark machine 60, system equipment of take-up unit 70 and parallel storage and feeding belt unit 20.

[0042] The wire storage and release unit 10 includes an active wire release mechanism 12, a wire / cable core 11, a pair of movable rollers B 14 and three fixed rollers A 13. The arrangement enables the movable roller B 14 to move freely up and down.

[0043] The longitudinal swivel unit 30 includes four fixed roller sets E 31 , the horn bundle mold 32 and the wire / cable core 11, in order of the direction of travel of the wire / cable core 11, the fixed roller set E 31 is connected in series to the horn The upstream of the bundle mold 32 a...

Embodiment 2

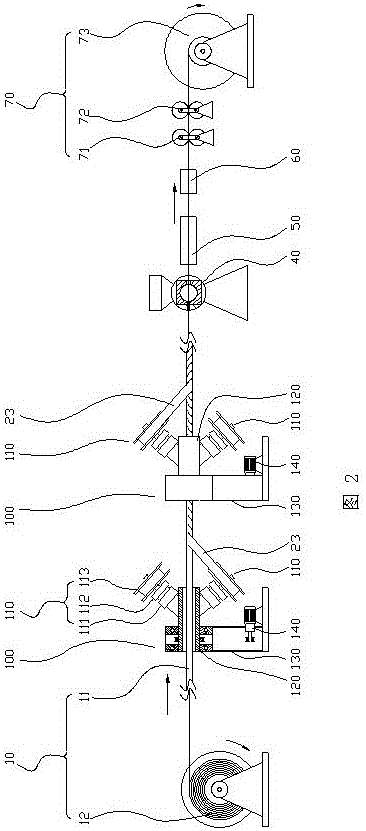

[0049] see figure 2 , which discloses the winding and covering mechanism (embodiment 2) of the ceramic wire / cable core manufacturing system of the present invention, including the storage and release line unit 10 in series, two winding units 100 clockwise and counterclockwise, a set of protective Jacket extruding unit 40, cooling and heating unit 50, high-voltage spark machine 60, take-up unit 70" system equipment.

[0050] The pay-off unit 10 includes an active pay-off machine 12, a wire / cable core 11 and a tension control system 71. The tension control system 71 is arranged at the take-up end. The pay-off mechanism 12 and the tension control system 71 use PLC to control the line speed and tension.

[0051] The winding unit 100 includes a belt feeding mechanism 110, a revolving hollow shaft 120, a bracket 130 and a revolving motor 140; in order of the direction of travel of the wire / cable core 11, two sets of winding units 100 are immediately adjacent to and connected in ser...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com