Engine nano curing agent and its preparation method and application

A curing agent and engine technology, applied in the direction of lubricating composition, petroleum industry, etc., to achieve the effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

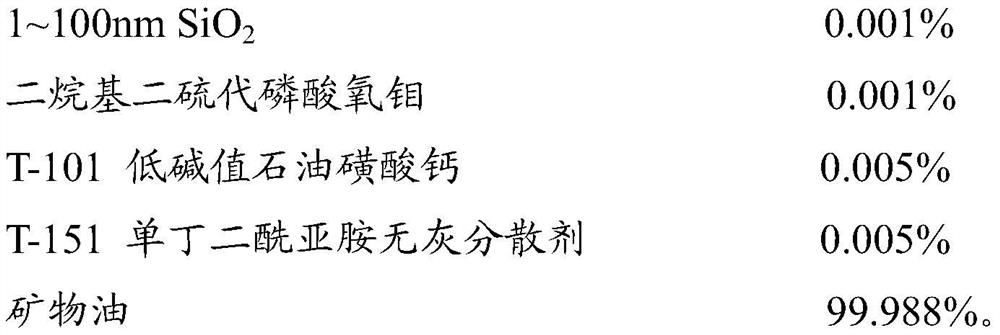

[0030] A kind of engine nano maintenance agent, is made up of the following components of mass percentage:

[0031]

[0032] The preparation method of the above-mentioned engine nano curing agent comprises:

[0033] Step 1: 0.001% SiO with a particle size of 1-100nm 2 , 0.001% oxymolybdenum dialkyl dithiophosphate, 0.005% T-101 low alkali value calcium petroleum sulfonate, 0.005% T-151 monosuccinimide ashless dispersant, magnetic stirring and mixing to form a nanomaterial solution .

[0034] Step 2: magnetically stir and mix the nanomaterial solution and 99.988% mineral oil to form a mixed solution.

[0035] Step 3: Homogenize the mixed liquid by high-speed mechanical stirring to obtain a nano engine maintenance agent.

Embodiment 2

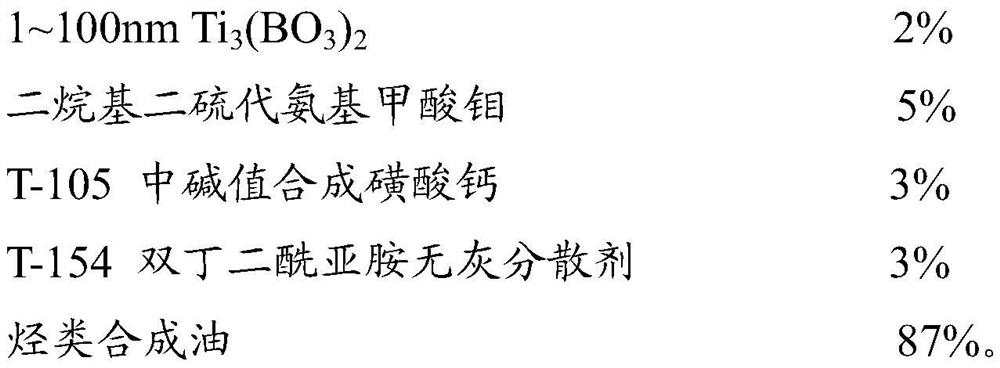

[0037] A kind of engine nano maintenance agent, is made up of the following components of mass percentage:

[0038]

[0039] The preparation method of the above-mentioned engine nano curing agent comprises:

[0040] Step 1: 2% Ti with a particle size of 1-100nm 3 (BO 3 ) 2 , 5% molybdenum dialkyldithiocarbamate, 3% T-105 medium base number synthetic calcium sulfonate, 3% T-154 bis-succinimide ashless dispersant, magnetic stirring and mixing to form a nanomaterial solution .

[0041] Step 2: magnetically stir and mix the nanomaterial solution and 87% hydrocarbon synthetic oil to form a mixed solution.

[0042] Step 3: Homogenize the mixed liquid by high-speed mechanical stirring to obtain a nano engine maintenance agent.

Embodiment 3

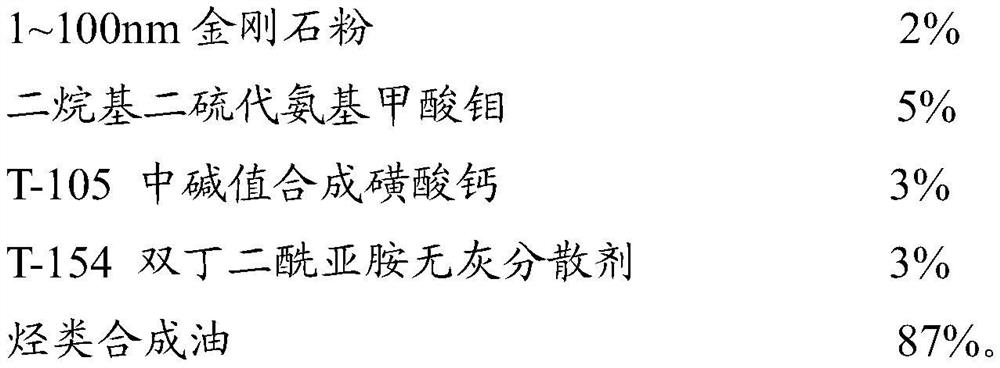

[0044] A kind of engine nano maintenance agent, is made up of the following components of mass percentage:

[0045]

[0046] The preparation method of the above-mentioned engine nano curing agent comprises:

[0047] Step 1: 2% diamond powder with a particle size of 1-100nm, 5% molybdenum dialkyl dithiocarbamate, 3% T-105 medium-base synthetic calcium sulfonate, 3% T-154 bis-succinyl Amine ashless dispersant, magnetic stirring to mix evenly to form a nanomaterial solution.

[0048] Step 2: magnetically stir and mix the nanomaterial solution and 87% hydrocarbon synthetic oil to form a mixed solution.

[0049] Step 3: Homogenize the mixed liquid by high-speed mechanical stirring to obtain a nano engine maintenance agent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com