Fashionable rubber boot having photochromic property in appearance, coating for fashionable rubber boot and preparation method thereof

A technology of photochromism and rubber boots, which is applied in the field of rubber boots manufacturing, can solve the problems of plain visual perception, flat and monotonous visual perception, and not bright colors, etc., achieve bright and colorful colors, improve photochromic performance, and increase fashion effects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

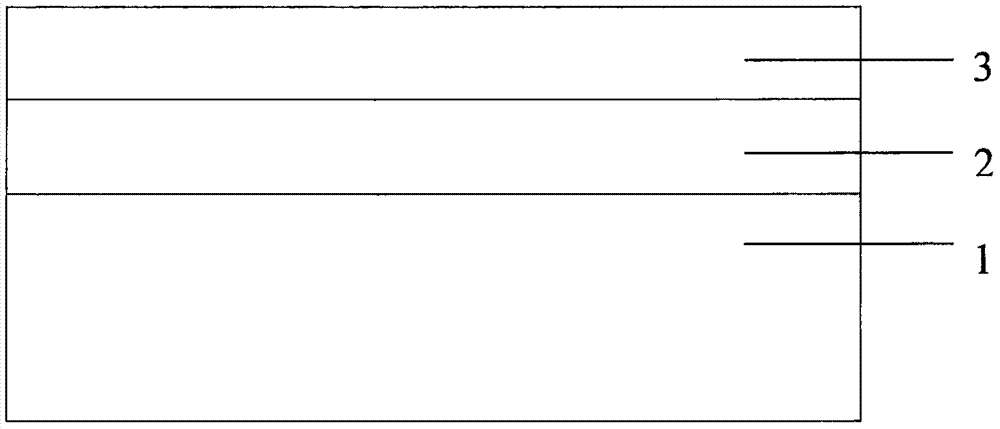

[0031] Embodiment 1: A fashion rubber boot with photochromic appearance, including a boot body, a sole, and a heel. It is characterized in that a layer of photochromic coating 2 is dipped or sprayed on the surface of the outer rubber layer of the integrally formed full rubber boot 1 including the boot body, sole and heel, and then dipped or sprayed with a layer of varnish after drying in an oven 3. The coating for the photochromic coating can be prepared by using spiropyran photochromic compounds to obtain rubber through banburying, and then dissolving the rubber in toluene or gasoline.

[0032] The preparation method includes integrally forming a full-rubber boot including a boot body, a shoe sole, and a heel, which is characterized in that the surface of the full-rubber boot 1 is dipped or sprayed with a coating containing a spiropyran photochromic compound, and hung on a running chain cable Enter the oven to dry, the baking temperature is 35°C, and the baking time is 2 min...

Embodiment 2

[0033] Embodiment 2: A fashion rubber boot with photochromic appearance, including a boot body, a sole, and a heel. It is characterized in that a layer of photochromic coating 2 is dipped or sprayed on the surface of the outer rubber layer of the integrally formed full rubber boot 1 including the boot body, sole and heel, and then dipped or sprayed with a layer of varnish after drying in an oven 3. The paint for the photochromic coating can be produced by using spiropyran photochromic compounds and fluorescent pigments through banburying to obtain rubber, and then dissolving the rubber in toluene or gasoline.

[0034] The preparation method includes integrally forming a full-rubber boot including a boot body, a shoe sole, and a heel, and is characterized in that the surface of the full-rubber boot 1 is dipped or sprayed with a dipping or spraying solution containing a spiropyran photochromic compound and a fluorescent pigment, Hang it on the running chain cable and enter the ...

Embodiment 3

[0035] Embodiment 3: A fashion rubber boot with photochromic appearance, including a boot body, a sole, and a heel. It is characterized in that a layer of photochromic coating 2 is dipped or sprayed on the surface of the outer rubber layer of the integrally formed full rubber boot 1 including the boot body, sole and heel, and then dipped or sprayed with a layer of varnish after drying in an oven 3. The components of the coating for the photochromic coating include by weight percentage: 4.5% butadiene rubber, 1.9% ethylene propylene rubber, 0.14% thiazole accelerator, 0.40% zinc oxide active agent, 0.13% sulfur, spiropyridine Furan photochromic compound 1.81%, acrylate leveling agent 0.07%, silicone oil 0.05%, amino resin 1.0%, toluene 39%, gasoline 51%.

[0036] Wherein, the preparation method of the photochromic coating of the fashion rubber boots with photochromic appearance specifically includes the following steps:

[0037] (1) Ethylene-propylene rubber is plasticized 20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com