Nano WO3 photochromic powder and preparation method thereof

A photochromic and nano-technology, applied in the direction of color-changing fluorescent materials, chemical instruments and methods, tungsten oxide/tungsten hydroxide, etc., to achieve the effect of improving photochromic ability, improving dispersibility, and enhancing surface activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

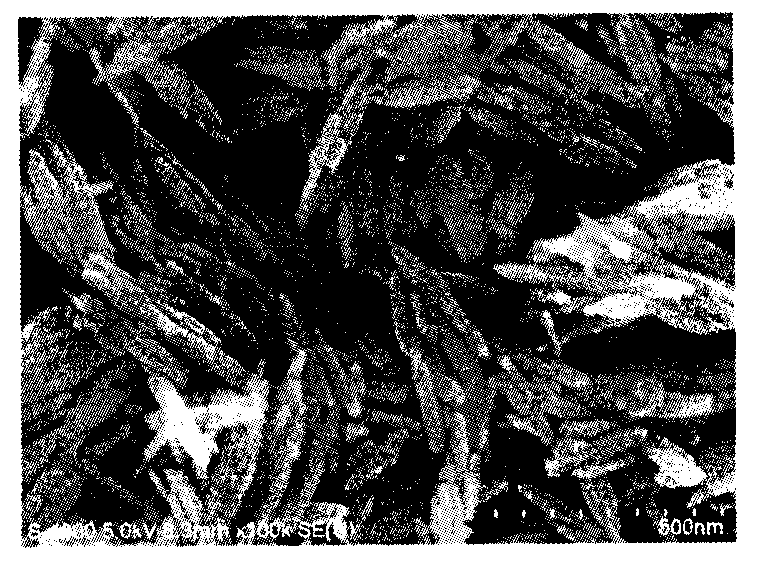

[0019] First, using sodium tungstate as the tungsten source, prepare 1mol / L Na 2 WO 4 Solution 100ml, and 10ml of oxalic acid solution with a concentration of 1.0mol / L was added dropwise under the stirring of a magnetic stirrer at 400-600r / min, and then the pH value of the solution was adjusted to 1.0 by using HCl with a concentration of 37-38% by mass. Then the obtained reaction system was stirred and homogenized for 4 hours, then put into a hydrothermal kettle for hydrothermal reaction at 100° C. for 48 hours, and then the product powder was collected and washed. The reaction product is washed repeatedly with distilled water until the pH value of the clear liquid is between 6.5 and 7.5, and then washed with absolute ethanol to remove residual water-soluble impurities and excess oxalic acid therein. Finally, put the reacted powder into a vacuum drying oven and dry it for 1 hour under the conditions of a vacuum degree of 0.085 and a temperature of 50°C to obtain nano-photochr...

Embodiment 2

[0022] The hydrothermal reaction temperature in the hydrothermal kettle is 80°C, and other conditions are the same as in Example 1 to prepare nano-photochromic WO 3 Powder, the measured chromaticity value of the powder is 3.132. After 20 minutes of ultraviolet light irradiation, the powder turns blue, and its chromaticity value is 55.874. It fades after being moved into a dark place for 1.5 hours, and its chromaticity value is 3.308.

[0023] Example 2

[0024] The nano-WO that embodiment 1 makes 3 The nanophotochromic powder sample was tested for its photochromic performance between 12:00 noon and 14:00 on a sunny summer day in southern China. The chromaticity value was 48.631 after 20 minutes of light, and faded after being moved into a dark place for 2 hours. The chromaticity value was 3.108. .

PUM

| Property | Measurement | Unit |

|---|---|---|

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com