Method for preparing tobermorite by using silicon-calcium slag

A technology of tobermorite and calcium silicate slag, which is applied in the field of preparing tobermorite with calcium silicate slag, which can solve the problems of high raw material requirements, long time required, and increased production costs, and achieve easy operation and low cost , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

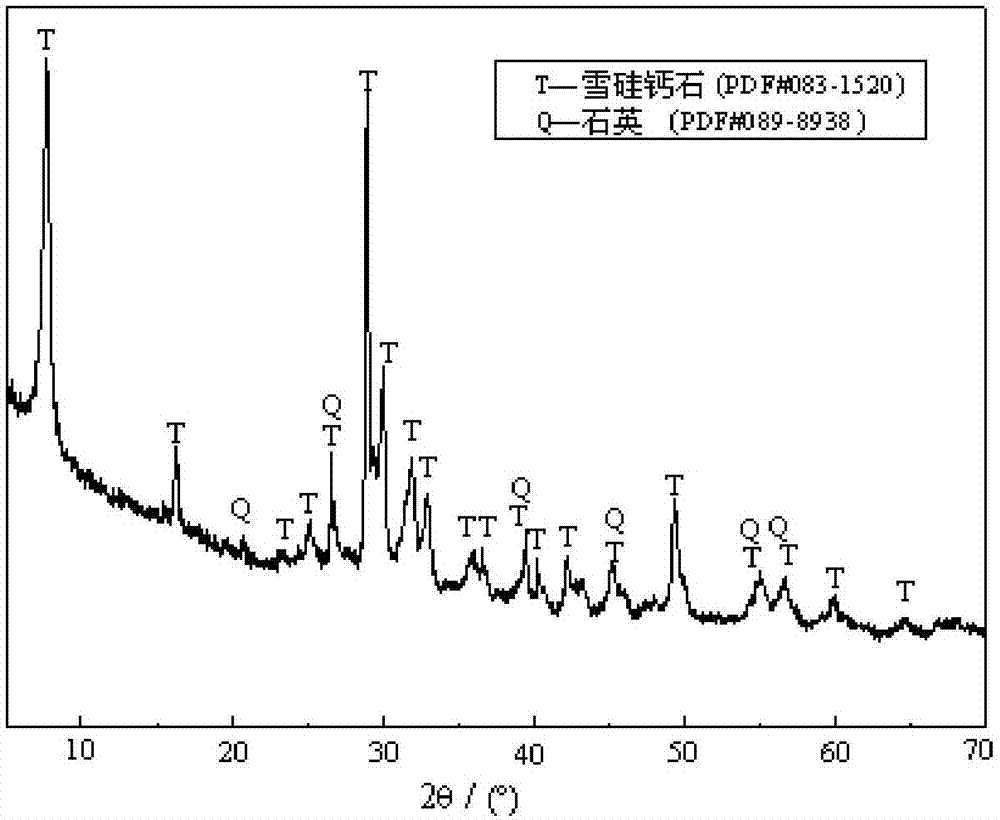

Image

Examples

Embodiment 1

[0031] The silicon-calcium slag used in this example was taken from an alumina plant in Hohhot, Inner Mongolia, and the quartz sand was taken from the Kubuqi Desert in Ordos, Inner Mongolia. The chemical compositions are shown in Table 1 and Table 2, respectively.

[0032] Table 1 Chemical composition of silicon calcium slag

[0033] Calcium silicon slag CaO SiO 2

al 2 o 3

Fe 2 o 3

Na 2 o

MgO Content (wt%) 56.28 27.54 6.23 1.33 2.98 1.78

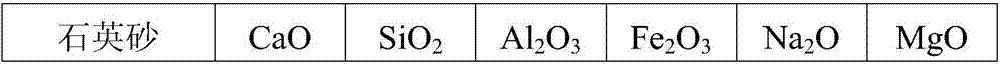

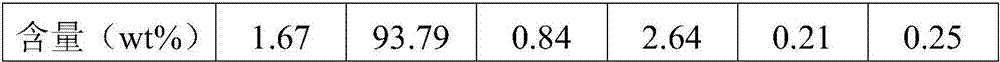

[0034] Table 2 Chemical composition of quartz sand

[0035]

[0036]

[0037] First, mix 100 parts by weight of the above-mentioned calcium silicate slag with 29 parts by weight of the above-mentioned quartz sand, and then use a ball mill to grind the mixture until all particle sizes are less than 0.2 mm to obtain a mixture; the molar ratio of calcium to silicon in the mixture is 1:0.9.

[0038] Add 1935 parts by weight of water (with a liquid-solid ratio of 15) to the above mixt...

Embodiment 2

[0042] The silicon-calcium slag used in this example was obtained from an alumina plant in Hohhot, Inner Mongolia, and the silica fume was obtained from a metallurgical group in Ordos, Inner Mongolia. The chemical compositions are shown in Table 3 and Table 4, respectively.

[0043] Table 3 The chemical composition of silicon-calcium slag

[0044] Calcium silicon slag CaO SiO 2

al 2 o 3

Fe 2 o 3

Na 2 o

MgO Content (wt%) 58.29 25.45 5.83 1.83 3.56 0.82

[0045] Chemical composition of table 4 silica fume

[0046] Silica fume CaO SiO 2

Al 2 o 3

Fe 2 o 3

Na 2 o

MgO Content (wt%) 2.78 89.27 2.98 1.64 1.57 1.25

[0047] First, mix 100 parts by weight of the above-mentioned calcium silicate slag and 31.9 parts by weight of the above-mentioned silica fume, and then use a ball mill to grind the mixture until all particle sizes are less than 0.15mm to obtain a mixture; the...

Embodiment 3

[0052] The silicon-calcium slag used in this example was taken from an alumina plant in Hohhot, Inner Mongolia, and the white carbon black was self-made by injecting carbon dioxide into desilication lye, and its chemical composition is shown in Table 5 and Table 6, respectively.

[0053] Table 5 Chemical composition of silicon calcium slag

[0054] Calcium silicon slag CaO SiO 2

Al 2 o 3

Fe 2 o 3

Na 2 o

MgO Content (wt%) 55.74 27.89 5.96 1.57 2.87 1.05

[0055] Table 6 Chemical composition of white carbon black

[0056] Silica CaO SiO 2

al 2 o 3

Fe 2 o 3

Na 2 o

MgO Content (wt%) 0.24 72.31 1.02 0.21 1.57 0.45

[0057] First, mix 100 parts by weight of the above-mentioned silicon-calcium slag and 34.2 parts by weight of the above-mentioned white carbon black, and then use a ball mill to grind the mixture until all particle sizes are less than 0.12 mm to obtain a mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Moisture content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com