Compound powder product for nutritious meal and preparation method thereof

A compound powder and nutritious meal technology, which is applied in food drying, food processing, food processing, etc., can solve problems affecting health, increasing organ burden, weight gain, etc., and achieves the effect of easy eating, improving body vitality, and comprehensive ingredients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1: A kind of nutritious meal compound powder product

[0034] 1. Raw materials include: 5000g of brown rice, 5000g of millet, 5000g of wheat, 5000g of quinoa, 5000g of oats, 5000g of buckwheat, 5000g of corn, 5000g of barley kernels; 2000g of edible fungi Hericium erinaceus, 2000g of Flammulina velutipes, 2000g of shiitake mushrooms, 2000g of Agaricus blazei , Tremella 2000g, Fungus 2000g, Cordyceps militaris 2000g; fruits and vegetables pumpkin 12000g, papaya 12000g, apple 12000g, carrot 12000g, lotus seeds 2000g, walnut kernel 2000g, lotus root 12000g, konjac 12000g; 10000g, bergamot 10000g, lily 1000g, sand ginseng 10000g, polygonatum 10000g, yam 6000g, kudzu root 6000g; and collagen powder 5000g, whey protein powder 5000g, soybean protein isolate powder 5000g, inulin 4000g, papaya enzyme 500g, vitamin C 500g .

[0035] 2. Preparation method:

[0036] (1) 5000g brown rice, 5000g millet, 5000g wheat, 5000g quinoa, 5000g oats, 5000g buckwheat, 5000g corn, ...

Embodiment 2

[0048] Embodiment 2: A kind of nutritious meal compound powder product

[0049] 1. The raw material composition and preparation method are the same as in Example 1. The obtained grain puffed powder, dried fruit and vegetable powder, dried edible fungus powder, yam and other dried powder, Chinese herbal medicine active substance extraction powder totaled 75080g, collagen powder 5000g, whey protein powder 5000g, soybean protein isolate powder 5000g, inulin 4500g, vitamin C500g was placed in a mixer for mixing, and the mixing time was 20 minutes to obtain a uniform mixed powder. The water content of the mixed powder is 6.3wt%. The loss rate is 5%.

[0050] 2. Packaging. Aseptically filled and packaged by a powder particle packaging machine, the packaging material is a medical aluminum film bag. The temperature of the packaging process workshop is 20°C-24°C, and the humidity is 45-65%.

Embodiment 3

[0051] Embodiment 3: A kind of nutritious meal compound powder product

[0052] 1. The raw material composition and preparation method are the same as in Example 1. The obtained puffed grain powder, dried fruit and vegetable powder, dried edible fungus powder, dried powder such as yam, Chinese herbal medicine active substance extraction powder totaled 76050g, collagen powder 5000g, whey protein powder 5000g, soybean protein isolate powder 5000g, inulin 4500g, vitamin C500g was placed in a mixer for mixing, and the mixing time was 20 minutes to obtain a uniform mixed powder. The water content of the mixed powder is 6.3wt%. The loss rate is 4%.

[0053] 2. Packaging. Aseptically filled and packaged by a powder particle packaging machine, the packaging material is a medical aluminum film bag. The temperature of the packaging process workshop is 20°C-24°C, and the humidity is 45-65%.

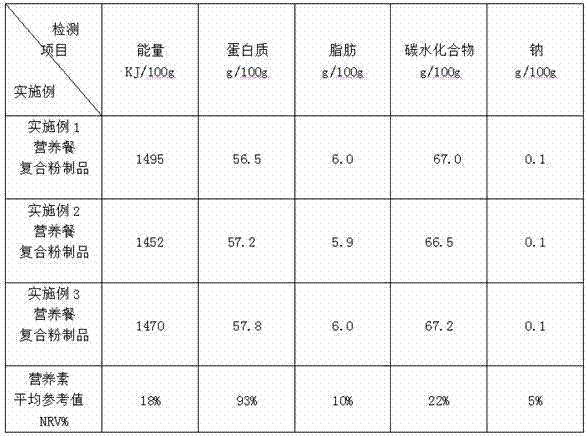

[0054] Nutrient ingredient list of nutritional meal compound powder products

[0055]

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

| Vitality | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com