Solar silicon wafer cutting fluid based on shear thickening mechanism, and preparation method thereof

A technology of solar silicon wafer and thickening mechanism, applied in the direction of lubricating composition, etc., can solve the problems of high diamond wire cutting cost, poor cutting quality and high cutting cost, so as to reduce cutting cost, low cutting cost and good cutting surface quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The invention provides a cutting fluid for solar silicon wafers based on a shear thickening mechanism. The cutting fluid is composed of micro / nano silicon dioxide particles, a dispersion medium and SiC powder. / Nano silica particles, forming a cutting fluid with shear thickening effect. Its preparation method comprises the following steps:

[0027] 1. Pretreatment of micro / nano silica: Take a certain amount of micro / nano particles and dissolve them in the pretreatment dispersion medium. The mass ratio of micro / nano silica to the pretreatment dispersion medium is 1:50~60. Stir for 30-60min at 800-1000r / min;

[0028] 2. Preparation of micro / nano silica dispersion system: Weigh 0.3 to 0.6 parts by weight of the micro / nano silica solution pretreated in step 1, add it to 0.7 to 0.4 parts by weight of the dispersion medium, and mix it at 800 Stir for 30-60 minutes under the condition of ~1000r / min, and then use an ultrasonic cleaner to ultrasonically disperse for 30-60 minu...

Embodiment 1

[0037] Take 250ml of hydroxyl silicone oil and add it to 250ml of ethylene glycol, and stir evenly in a 3L container; take 10g of nano-silica particles, add them to the above dispersion medium, and stir at 950r / min for 60min; after the dispersion is uniform, add Stir 500ml PEG200 for 40min at 800r / min; then use an ultrasonic cleaner to ultrasonically disperse for 30min at a power of 200W to obtain a silica dispersion system; After the SiC powder was added, the mechanical stirring was continued for 2 hours to obtain a new type of shear thickening solar silicon wafer cutting fluid.

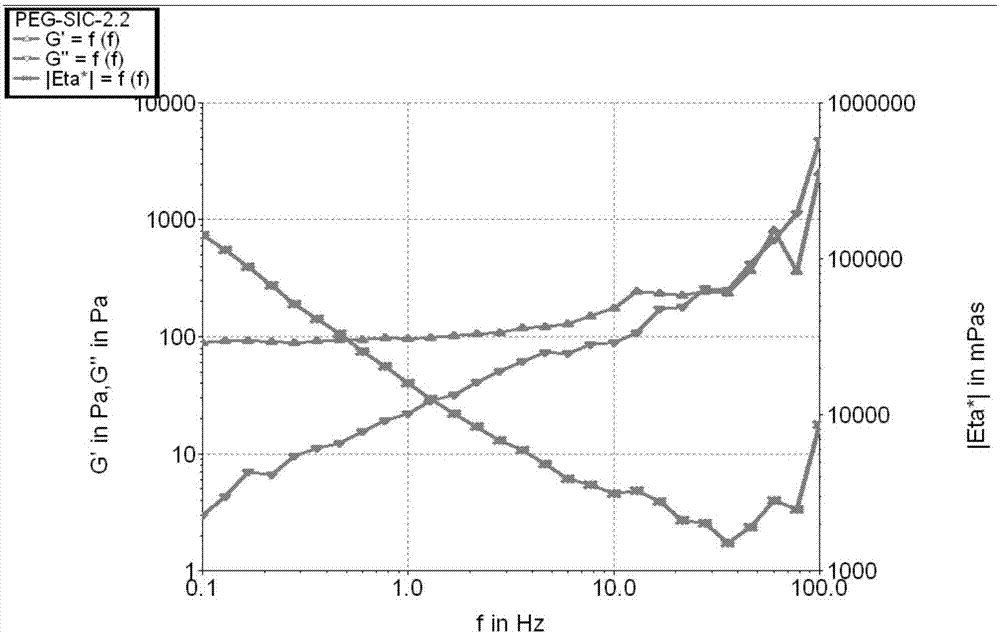

[0038] From attached figure 1 It can be seen that the cutting fluid has good shear thickening performance.

Embodiment 2

[0040] According to the preparation method and conditions of Example 1, diethylene glycol and PEG300 can also be used to obtain a cutting fluid in which silicon carbide is dispersed in a silicon dioxide dispersion system;

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com