A kind of drag reducing agent ultrafine powder mixing and grinding device

A technology of mixed grinding and ultrafine powder, which is applied in the direction of mixer, mixing method, transportation and packaging, etc., can solve the problem of increasing the impact force between the drag reducing agent and the rotor and stator of the grinding machine, and the small specific surface area of the acidizing and fracturing drag reducing agent , The effect cannot be fully exerted, etc., to achieve the effect of sufficient reaction, good grinding effect, and good stirring effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

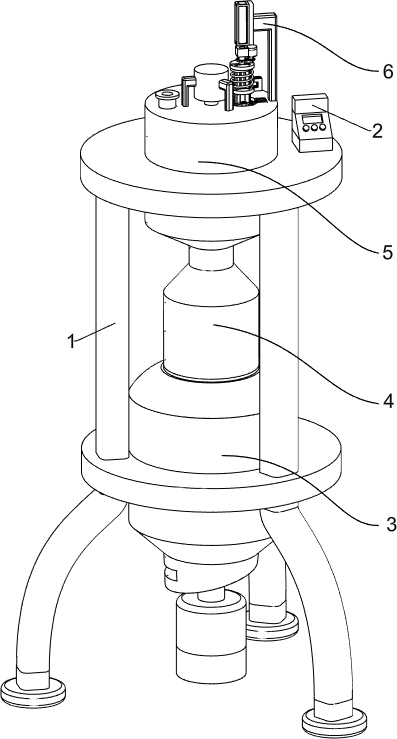

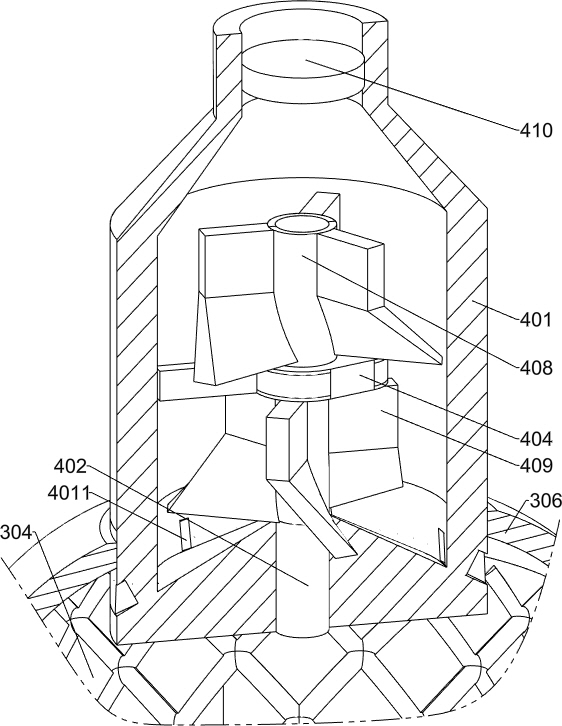

[0033] A drag reducing agent ultrafine powder mixing and grinding device, such as figure 1 As shown, it includes a bracket 1, the upper part of the bracket 1 is fixed with a console 2, the lower part of the bracket 1 is welded with a grinding mechanism 3 for material grinding, and the upper part of the grinding mechanism 3 is provided with a mixing and pressing mechanism 4 for material pressing , the mixing and pressing mechanism 4 pressurizes the drag-reducing agent, and the drag-reducing agent after the pressurization enters the grinding mechanism 3 and flows downward to be ground by the grinding mechanism 3. The impact between the pressurized drag-reducing agent and the grinding mechanism 3 The force increases to achieve a better grinding effect. The upper part of the bracket 1 is fixed with a stirring mechanism 5 for material stirring to achieve a better stirring effect. The stirring mechanism 5 is located above the mixing and pressing mechanism 4. The stirring mechanism 5 ...

Embodiment 2

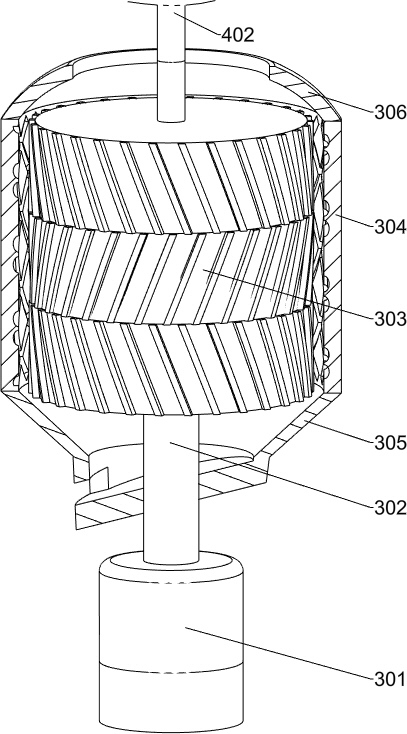

[0036] On the basis of Example 1, as figure 2 As shown, the grinding mechanism 3 includes a first servo motor 301, the first servo motor 301 is placed on the ground through the motor base, the first servo motor 301 is electrically connected to the console 2, and the output shaft end of the first servo motor 301 is welded with The first rotating shaft 302, the upper end of the first rotating shaft 302 is fixed with a rotor 303, the outer surface of the rotor 303 is circumferentially distributed with a number of helical teeth, the lower part of the bracket 1 is fixed with a stator 304, the inner surface of the stator 304 is set to be uneven, the rotor 303 cooperates with the stator 304 for material grinding. The lower part of the stator 304 is welded with a lower shell 305. The lower part of the lower shell 305 is inclined and used for material discharge, and one side of the lower shell 305 has a discharge port. , the upper part of the stator 304 is fixed with an upper casing 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com