Ornamental glass and manufacturing method thereof

A technology for decorative glass and its production method, which is applied in special decorative structures, decorative arts, and techniques for producing decorative surface effects, etc., which can solve the problems of no texture effect, reflection, peeling, etc., and achieve non-glare and soft vision Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

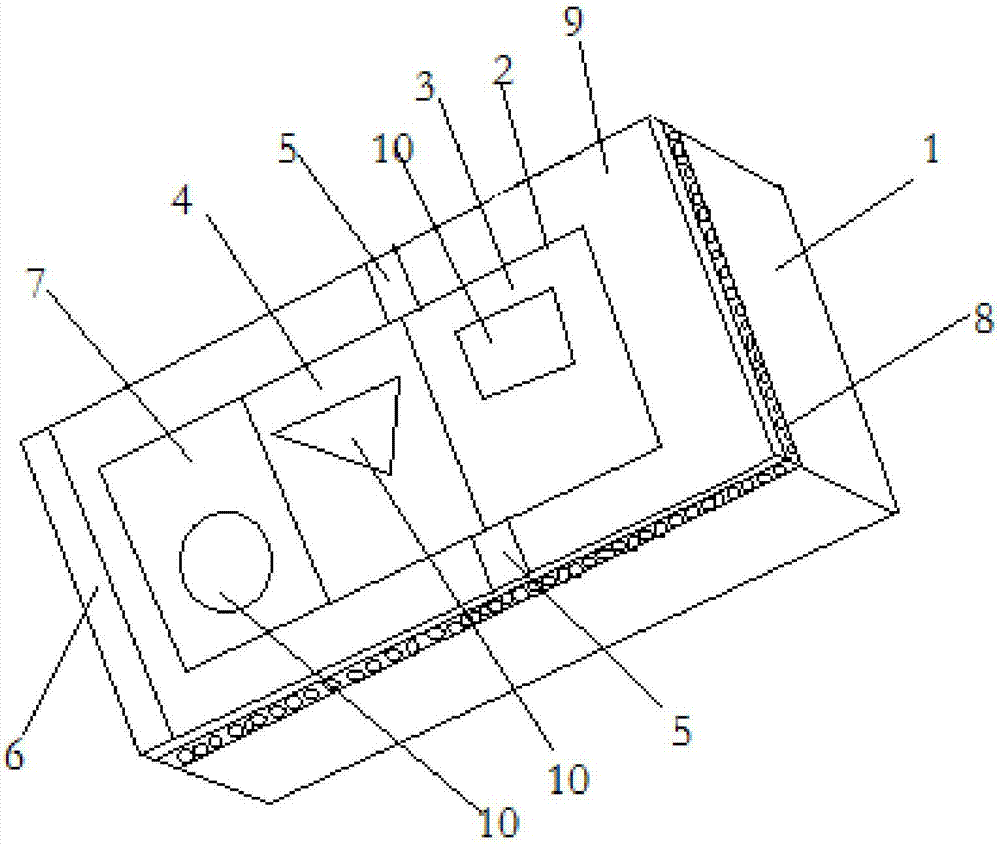

[0034] A decorative glass described in this embodiment includes tempered glass 1 as a bottom plate, and the tempered glass 1 is provided with a pattern area 2, and the pattern area 2 includes a sand sculpture area 3, a chemical liquid etching area 4, a waistline 5, a shading 6 and In the antique craft area 7, the toughened glass 1 is provided with a diamond powder layer 8, the diamond powder layer 8 is provided with an environmental protection paint layer 9, and the environmental protection paint layer 9 is pasted with an art glass patch 10, and the art glass patch 10 includes Ivory-like carved glass tiles, luminous-effect glass tiles, copper-like glass tiles and jade-like embossed glass tiles with glass effect.

[0035] The decorative glass is divided into imitation ivory carving series, jade luminous carving series, imitation copper carving series and imitation jade carving series according to the theme of the pattern area 2 and the attached art glass patch 10. According to t...

Embodiment 2

[0041] The manufacturing method of the decorative glass described in embodiment 1, comprises the steps:

[0042] 1) To engrave the bottom plate, use tempered glass 1 as the bottom plate, first use high-quality PVC self-adhesive adhesive paper to cover both sides and the surrounding of the tempered glass 1 and stick it tightly, then place the tempered glass 1 on the computer engraving machine, The pre-designed pattern is accurately engraved on the PVC self-adhesive adhesive paper of the tempered glass 1 to form the pattern area 2;

[0043] 2) Sandblasting and engraving, accurately remove the PVC self-adhesive paper in the area that needs sand sculpture in the pattern, then send the tempered glass 1 to the special sand making machine box, and perform sandblasting and engraving on the outline of the area that needs sand sculpture to form sand sculpture area 3 ;

[0044] 3) Etching with liquid medicine, accurately peel off the PVC self-adhesive paper surface of the tempered glass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com