Boat and boat group for hard alloy dewaxing process

A cemented carbide and boat technology, which is applied in the field of cemented carbide dewaxing boats and boat groups, can solve the problems of blocking wax vapor, increasing the concentration of wax vapor, and product dewaxing, so as to improve dewaxing Efficiency, stable product quality, and the effect of reducing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

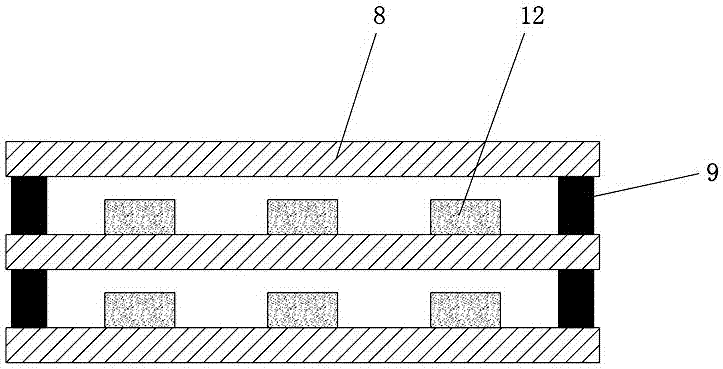

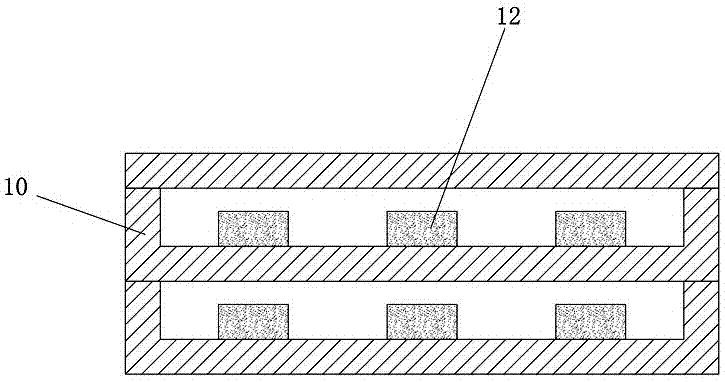

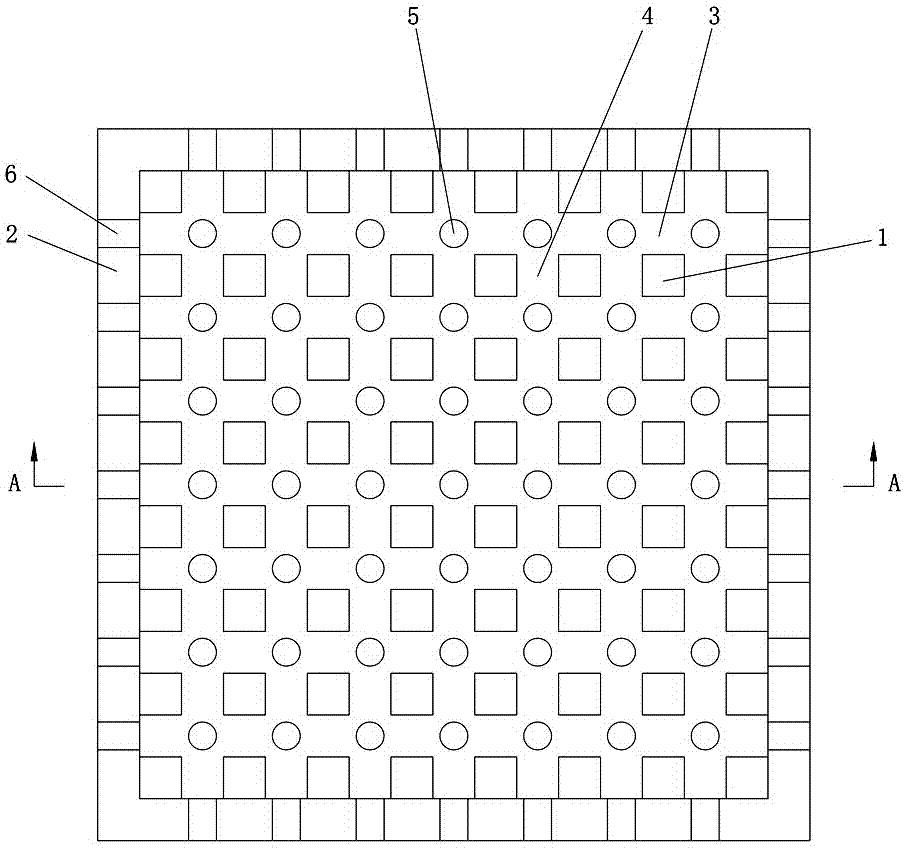

[0029] image 3 and Figure 4 Shown is an embodiment of the boat used in the cemented carbide dewaxing process of the present invention, the boat includes a bottom plate 1 and a side wall 2, the side wall 2 is surrounded by the outer edge of the front of the bottom plate 1, and the front of the bottom plate 1 There are more than one transverse diversion groove 3 and more than one longitudinal diversion groove 4, the transverse diversion groove 3 intersects with the longitudinal diversion groove 4, and the bottom plate 1 at the intersection is provided with a bottom plate through hole 5, and the side wall 2 More than one side wall through hole 6 is provided, and intersecting horizontal diversion grooves 3 and longitudinal diversion grooves 4 are arranged on the bottom plate 1, so that the products 12 placed on the surface can be overh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com