Enzyme dietary fiber and preparation technology thereof

A dietary fiber and preparation technology, applied in the direction of bacteria used in food preparation, yeast-containing food ingredients, food science, etc., can solve problems such as negative effects on the body, ineffective effects, diarrhea, etc., and achieve weight loss and removal of toxins in the body , improve the effect of the stomach

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

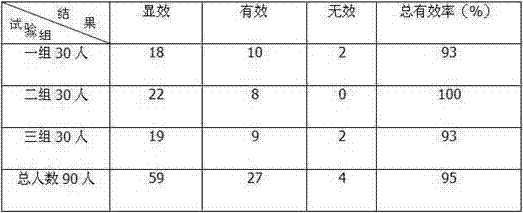

Examples

Embodiment 1

[0018] An enzyme dietary fiber comprises the following raw materials in parts by weight: 40 parts of enzyme powder, 2 parts of fructo-oligosaccharide, 12 parts of polydextrose, 20 parts of galacto-oligosaccharide, 6 parts of oat flour and 8 parts of purslane powder.

[0019] The preparation method of the enzyme powder is as follows: according to the mass ratio of 2:1:1:1:1:3:2:1, fresh apples, persimmons, hawthorns, kiwis, pineapples, papaya, blueberries and psyllium Subshells, crushed into small pieces below 1 cubic centimeter, the volume is 2m 3 In the fermentation tank, the charging volume of the fermentation tank is 1.6m 3 , inoculate according to 10 9 -10 10 cfu / m 3 Inoculate Saccharomyces cerevisiae, Lactobacillus acidophilus (strain No. R0052), Lactobacillus paracasei (strain No. GM080), Lactobacillus rhamnosus (strain No. R0011) and mix well, and culture at room temperature for 30-60 days , freeze-dried, and crushed at low temperature to obtain enzyme powder.

[...

Embodiment 2

[0025] An enzyme dietary fiber comprises the following raw materials in parts by weight: 30 parts of enzyme powder, 1.5 parts of fructo-oligosaccharide, 10 parts of polydextrose, 15 parts of galacto-oligosaccharide, 5 parts of oat flour and 6 parts of purslane powder.

[0026] The preparation method of the enzyme powder is as follows: according to the mass ratio of 2:1:1:1:1:3:2:1, fresh apples, persimmons, hawthorns, kiwis, pineapples, papaya, blueberries and psyllium Subshells, crushed into small pieces below 1 cubic centimeter, the volume is 2m 3 In the fermentation tank, the charging volume of the fermentation tank is 1.6m 3 , inoculate according to 10 9 -10 10 cfu / m 3 The amount of inoculum was inoculated with Saccharomyces cerevisiae, Lactobacillus acidophilus (strain number R0052), Lactobacillus paracasei (strain number GM080) and Lactobacillus rhamnosus (strain number R0011), stirred evenly, and cultured at room temperature for 30-60 days , freeze-dried, and crushe...

Embodiment 3

[0032] An enzyme dietary fiber, comprising the following raw materials in parts by weight: 50 parts of enzyme powder, 3 parts of fructo-oligosaccharide, 10-15 parts of polydextrose, 25 parts of galacto-oligosaccharide, 8 parts of oat flour and 10 parts of purslane powder .

[0033] The preparation method of the enzyme powder is as follows: according to the mass ratio of 2:1:1:1:1:3:2:1, fresh apples, persimmons, hawthorns, kiwis, pineapples, papaya, blueberries and psyllium Subshells, crushed into small pieces below 1 cubic centimeter, the volume is 2m 3 In the fermentation tank, the charging volume of the fermentation tank is 1.6m 3 , inoculate according to 10 9 -10 10 cfu / m 3 The amount of inoculum was inoculated with Saccharomyces cerevisiae, Lactobacillus acidophilus (strain number R0052), Lactobacillus paracasei (strain number GM080), and Lactobacillus rhamnosus (strain number R0011), stirred evenly, and cultured at room temperature for 30-60 days , freeze-dried, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com