Preparation method of gold octahedron-graphene composite nanomaterial and sensor chip based thereon and its application

A graphene composite and nanomaterial technology, which is applied in the fields of nanotechnology, nanotechnology, and analytical materials for materials and surface science, and can solve the problems of high cost, slow detection reaction speed, and insufficient sensitivity of trace heavy metal ions. , to achieve strong loading capacity, low detection limit, and good absorption of trace heavy metal ions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Example 1 Preparation of gold octahedron-graphene composite nanomaterials and application of the structure to prepare sensor chips

[0028] 1. Preparation of gold octahedron-graphene composite nanomaterials

[0029] Follow the steps below:

[0030] (1) Preparation of gold octahedral nanostructures

[0031] Prepare gold octahedron nanostructure by chemical method, at first the ethylene glycol of 20mL, the polyethylene (Poly) of 0.4mL is added the phosphoric acid (H 3 PO 4 ), after mixing and stirring for 2 minutes, add 0.02mL of chloroauric acid (HAuCl 4 ), reacted at room temperature for 15 minutes, and then kept heating at 195°C for 30 minutes in an oil bath. During the reaction, the solution changed from colorless to purple and then to brown, and finally a gold octahedral nanostructure was obtained. The size of the obtained gold octahedral nanostructure is 80-100nm, and its structure is as follows: figure 1 shown.

[0032] (2) Prepare graphene film material

[...

Embodiment 2

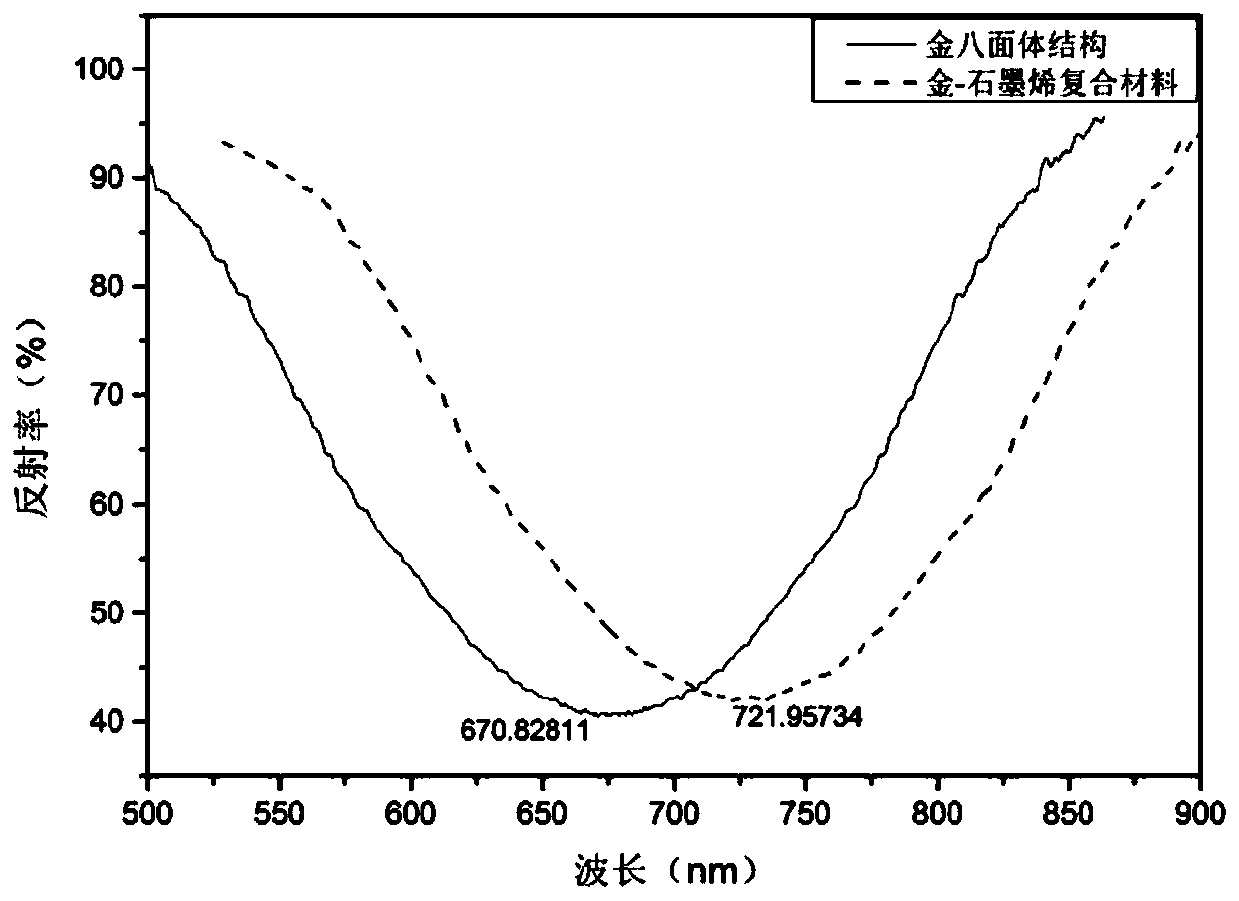

[0040] Embodiment 2 SPR optical fiber sensor using gold octahedron-graphene composite nanomaterial and its application

[0041] 1. Construction of SPR fiber optic sensor using gold octahedron-graphene composite nanomaterials

[0042] Utilize the sensor chip that is plated with gold octahedron-graphene composite nano film prepared in embodiment 1, construct SPR fiber optic sensor, this SPR fiber optic sensor is made up of following assembly (its structural representation is as follows Figure 4 Shown): (1) Light source component - broadband light source (HL-2000), the wavelength range is 350nm-1050nm, (2) Optical transmission component - optical fiber for transmitting optical signals, (3) SPR sensor chip - ——that is, the sensor chip coated with gold octahedron-graphene composite nanofilm prepared in Example 1, used for light path reflection, enhancing adsorption and photoelectric characteristics, (4) water tank——for holding detection samples, (5) ) accepts components - spectru...

Embodiment 3

[0048] (1) Preparation of gold octahedral nanostructures

[0049] Prepare gold octahedral nanostructure by chemical method, at first the ethylene glycol of 18mL, the polyethylene (Poly) of 0.39mL is added the phosphoric acid (H 3 PO 4 ), after mixing and stirring for 2 minutes, add 0.015mL of chloroauric acid (HAuCl 4 ), reacted at room temperature for 12 minutes, and then kept heating at 185° C. for 35 minutes in an oil bath. During the reaction, the solution changed from colorless to purple and then to brown, and finally a gold octahedral nanostructure was obtained. The size of the obtained gold octahedral nanostructure is about 100nm.

[0050] (2) Preparation of gold octahedron-graphene nanostructures

[0051] In the preparation process of the gold octahedron-graphene nanostructure, the prepared gold octahedron is diluted with 99.7% alcohol with a solubility of 14ml, and the gold octahedron solution is observed under the scanning electron microscope without large-scale a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com