Interlayer structure construction method of asphalt pavement

A technology of interlayer structure and construction method, applied in the field of traffic survey, can solve the problems of damage to the underlying layer structure, manual cleaning, waste of manpower and material resources, etc., and achieve strong resistance to deformation, prevent downward penetration, and increase shear strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

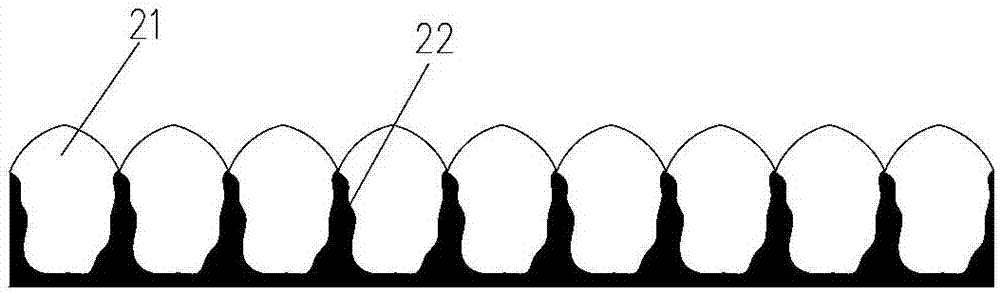

Image

Examples

Embodiment 1

[0065] 1 Technical requirements for rubber asphalt

[0066] Coarse rubber powder should be used for spreading rubber asphalt, such as 30 mesh. In order to ensure the stability of rubber asphalt quality, it is required to process and spread on the same day, and rubber asphalt should not exceed 24 hours from processing to spreading. The base asphalt for processing rubber asphalt should use grade A No. 70 road petroleum asphalt, and the external mixing amount of waste tire rubber powder is 22%; its quality should meet the requirements of current regulations.

[0067] 2 construction process

[0068] In order to ensure the construction quality of the rubber asphalt waterproof bonding layer, the cleaning of the underlying layer should be done well to ensure that all kinds of diseases of the underlying layer have been treated and the road surface is in a clean, dry and rough interface state; carry out trial sprinkling and determine some key points Construction parameters, and the u...

Embodiment 2

[0094] The difference with embodiment 1 is:

[0095] In step 1: the particle size of the rubber powder is 40 mesh, and the amount of the waste tire rubber powder added is 25%.

[0096] In step 2.3: the spreading amount of rubber asphalt is 2.4kg / m 2 ; The spreading temperature of rubber asphalt is controlled at 190°C.

[0097] In step 2.4: limestone material, the specification is 13mm; the spreading amount of crushed stone is generally 70% of the full pavement.

Embodiment 3

[0099] The difference with embodiment 1 is:

[0100] In step 1: the external mixing amount of waste tire rubber powder is 20%.

[0101]In step 2.3: the spreading amount of rubber asphalt is 2.0kg / m 2 ; The spreading temperature of rubber asphalt is controlled at 180°C.

[0102] In step 2.4: limestone material, the specification is 16mm; the spreading amount of crushed stone is generally 70% of the full pavement.

[0103] The road sections constructed in the above three embodiments were tested one week and one month after the construction, and the test results showed that the road surface has excellent water tightness and shear resistance, both of which meet the national standards.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com