Two-component organosilicon pouring sealant and preparation method thereof

A silicone potting glue, a two-component technology, applied in the field of potting glue, can solve the problems of silicone potting glue production efficiency and product quality, catalyst poisoning, etc., to achieve excellent bonding performance, easy operation, and use less effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The preparation of embodiment 1 base material

[0032] 100 parts of linear vinyl polydimethylsiloxane with a viscosity of 500 mPa.s and a vinyl content of 0.4 wt%, 260 parts of aluminum oxide with an average particle size of 5 μm, and aluminum hydroxide with an average particle size of 10 μm 40 parts were added into a vacuum kneader and mixed evenly, and then dehydrated and blended for 60 minutes at a temperature of 140° C. and a vacuum degree of 0.08 Mpa to obtain a base material.

Embodiment 2

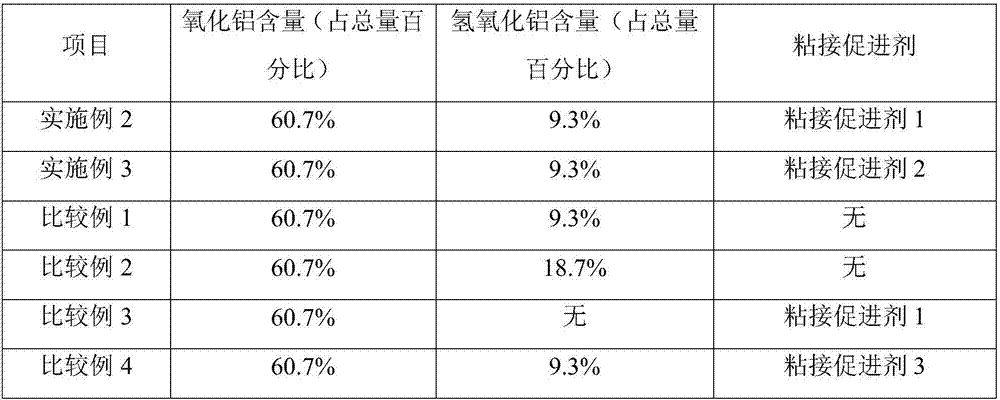

[0033] Example 2 Two-component silicone potting glue

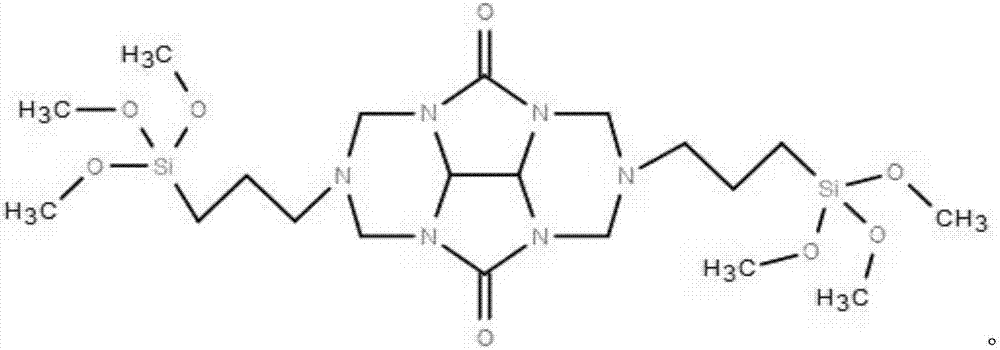

[0034] Two-component silicone potting compound, including equal mass of A component and B component; A component includes 100 parts of the base material of Example 1, platinum catalyst and 4 parts of adhesion promoter 1; the B component Including 100 parts of the base material of Example 1, 10 parts of crosslinking agent and 0.01 part of inhibitor; the platinum catalyst is a vinyl siloxane complex of chloroplatinic acid, wherein the content of platinum in the A component is 10ppm; The joint agent is a hydrogen-containing silicone oil with a hydrogen content of 0.36%, and the inhibitor is 1-ethynyl-1-cyclohexanol; the adhesion promoter 1 is a nitrogen-containing heterocyclic polycyclic siloxane selected from

[0035]

[0036] Its preparation method comprises the following steps:

[0037] S1: base material is prepared as in Example 1;

[0038] S2: Add the vinyl siloxane complex of chloroplatinic acid to 100 parts of the...

Embodiment 3

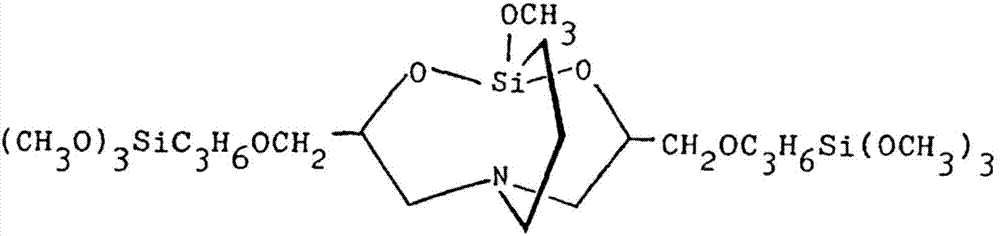

[0041] Example 3 Two-component silicone potting glue

[0042]Two-component silicone potting glue, including equal mass of A component and B component; A component includes 100 parts of the base material of Example 1, platinum catalyst and 4 parts of adhesion promoter 2; the B component Including 100 parts of the base material of Example 1, 10 parts of crosslinking agent and 0.01 part of inhibitor; the platinum catalyst is a vinyl siloxane complex of chloroplatinic acid, wherein the content of platinum in the A component is 10ppm; The joint agent is a hydrogen-containing silicone oil with a hydrogen content of 0.36%, and the inhibitor is 1-ethynyl-1-cyclohexanol; the adhesion promoter 2 is a nitrogen-containing heterocyclic polycyclic siloxane selected from

[0043] The preparation method is the same as in Example 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com