Chemically resistant outsole compound for labor insurance shoes and preparation method thereof

A technology of chemical corrosion resistance and mixed rubber, which is applied in the direction of shoe soles, footwear, applications, etc., can solve the problems of loss of protection, short life of labor insurance shoes, easy corrosion of soles, etc., to achieve reasonable ratio and improve plasticity and mastication efficiency, good chemical resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] This embodiment discloses a method for preparing a chemically resistant outsole rubber compound for labor insurance shoes according to claim 1, comprising the following steps:

[0027] (1) Preparation of peptizer masterbatch: get No. 3 imported cigarette sheet rubber and peptizer in the same weight portion as the peptizer and mix to make peptizer masterbatch;

[0028] (2) glue breaking: after neoprene rubber, EPDM rubber and remaining No. 3 imported smoke sheet glue are cut into small pieces by weight, they are respectively dropped into glue breaking machine and broken into rubber threads;

[0029](3) Mastication: Put the No. 3 imported tobacco sheet rubber filament into the open mill with a roller distance of 0.5mm or less and a roller temperature of 40°C to 50°C by using the Botong plasticating method. After plasticizing and thinning, Discharging and cooling, put the cooled rubber material into the open mill with a roll distance of 5mm~8mm, and add roller mastication,...

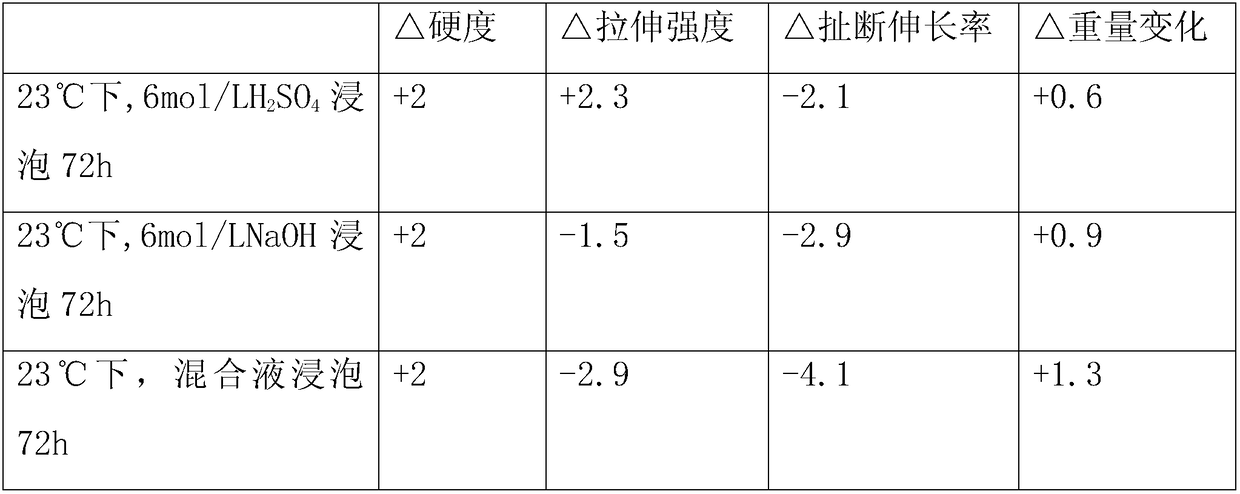

Embodiment 1

[0034] The labor insurance shoes of the present embodiment are chemically resistant outsole rubber mixes, and the rubber mix raw materials include the following components by weight: 65 parts of No. 3 imported smoked sheet rubber, 35 parts of chloroprene rubber, and 15 parts of EPDM rubber. 7 parts of coumarone resin, 10 parts of petroleum resin, 4 parts of stearic acid, 4 parts of nano zinc oxide, 2.5 parts of magnesium oxide, 1.5 parts of sulfur, 0.8 parts of accelerator Na-22, 1.2 parts of accelerator TBSI, 1.2 parts of anti-aging agent NBC, 2.4 parts of anti-aging agent RD, 23 parts of modified sepiolite powder, and 1 part of peptizer.

[0035] In this embodiment, the modified sepiolite powder is sepiolite powder whose surface is modified by a silane coupling agent.

[0036] The preparation method of the chemical corrosion-resistant outsole rubber compound for labor insurance shoes of the present embodiment comprises the following steps:

[0037] (1) Preparation of peptiz...

Embodiment 2

[0049] The labor insurance shoes of the present embodiment are chemically resistant outsole rubber mixes, and the rubber mix raw materials include the following components by weight: 62 parts of No. 3 imported smoked sheet rubber, 32 parts of neoprene rubber, and 12 parts of EPDM rubber. 6 parts of coumarone resin, 8 parts of petroleum resin, 3 parts of stearic acid, 3 parts of nano zinc oxide, 3 parts of magnesium oxide, 1 part of sulfur, 0.48 parts of accelerator Na-22, 0.72 parts of accelerator TBSI, anti-aging 1 part of agent NBC, 2 parts of anti-aging agent RD, 20 parts of modified sepiolite powder, and 0.8 part of peptizer.

[0050] In this embodiment, the modified sepiolite powder is sepiolite powder whose surface is modified by a silane coupling agent.

[0051] The preparation method of the chemical corrosion-resistant outsole rubber compound for labor insurance shoes of the present embodiment comprises the following steps:

[0052] (1) Preparation of peptizer masterb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com