Completely biodegradable fiber-reinforced starch foam tableware and its preparation method

A biodegradable, fiber-reinforced technology, used in table utensils, home utensils, coatings, etc., can solve problems such as the inability to achieve high foaming ratio of starch, no tableware waterproof and oil-proof treatment, and non-biodegradable polyvinyl alcohol, etc. Molding cycle, good water and oil resistance, and small foam pore size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

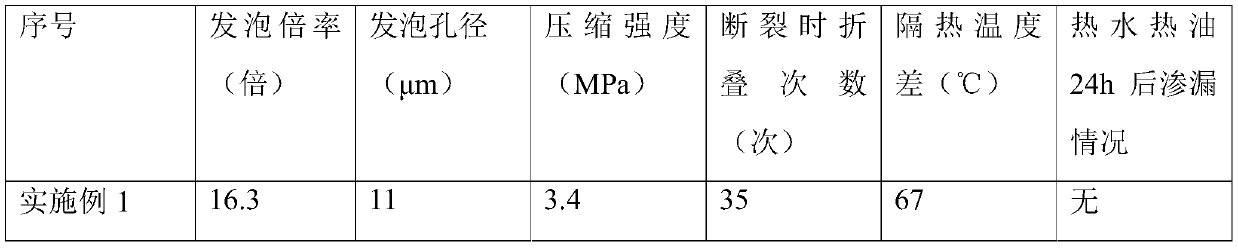

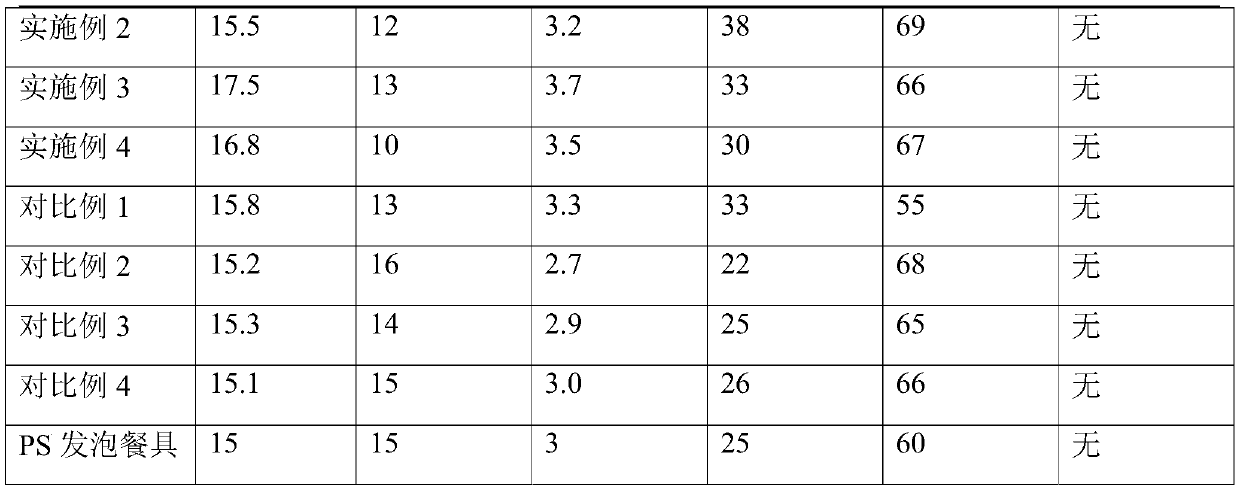

Examples

Embodiment 1

[0046] 50% tapioca starch (50 mesh), 20% polylactic acid short fiber (50D, 25mm), 10% polybutylene succinate powder (100 mesh), 5% 5000 mesh hydrotalcite ZnMg 3 al 2 (OH) 12 CO 3 mH 2 O is added in the mixer successively, stirred at normal temperature for 10 min, then added 3% diethanolamine, stirred at normal temperature for 15 min, finally added 10% foaming agent (water / stearic acid / baking soda=8 / 1 / 1 mass ratio), 2% 100-mesh glyceryl monostearate was stirred and mixed evenly at 40°C, then added to the mold, hot-pressed at 180°C for 40 seconds, and finally sprayed with a polybutylene terephthalate adipate film with a thickness of 10 μm. A completely biodegradable fiber-reinforced starch foam tableware is obtained.

Embodiment 2

[0048] 60% tapioca starch (100 mesh), 15% polylactic acid short fiber (100D, 10mm), 10% polybutylene terephthalate adipate powder (500 mesh), 3% 5500 mesh hydrotalcite ZnMg 3 al 2 (OH) 12 CO 3 mH 2 O is added in the agitator successively, stirred at normal temperature for 10 min, then added 3% triethanolamine, stirred at normal temperature for 15 min, finally added 8% foaming agent (water / palmitic acid / baking soda=6 / 2 / 2 mass ratio), 1 % 50 mesh glycerol monostearate was mixed evenly at 60°C, then added to the mold, hot-pressed at 250°C for 20 seconds, and finally sprayed with a polypropylene carbonate film with a thickness of 20 μm to obtain a completely biodegradable fiber-reinforced starch foam. soak tableware

Embodiment 3

[0050] 82% tapioca starch (150 mesh), 5% polyglycolic acid short fiber (10D, 50mm), 5% polybutylene terephthalate adipate powder (300 mesh), 1% 4500 mesh hydrotalcite ZnMg 3 al 2 (OH) 12 CO 3 mH 2 O is added in the mixer successively, stirred at normal temperature for 10 min, then added 1% monoethanolamine, stirred at normal temperature for 15 min, finally added 5% foaming agent (water / oleic acid / baking soda=7 / 2 / 1 mass ratio), 1 % 150 mesh glyceryl monostearate was stirred and mixed evenly at 50°C, then added to the mold, hot-pressed at 220°C for 60 seconds, and finally sprayed with a polybutylene succinate film with a thickness of 5 μm to obtain a completely biodegradable Fiber reinforced starch foam tableware.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com