Thermal jet printing head based on graphene-carbon nanotube composite structure and preparation method thereof

A carbon nanotube composite and carbon nanotube technology, which is applied in printing and other directions, can solve the problems of unstable closing, high contact resistance, and easy contamination of the printing chamber by UV curing glue, and achieve the effect of complete microfluidic structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0074] The preparation method of the above-mentioned thermal jet printing head mainly includes the following steps:

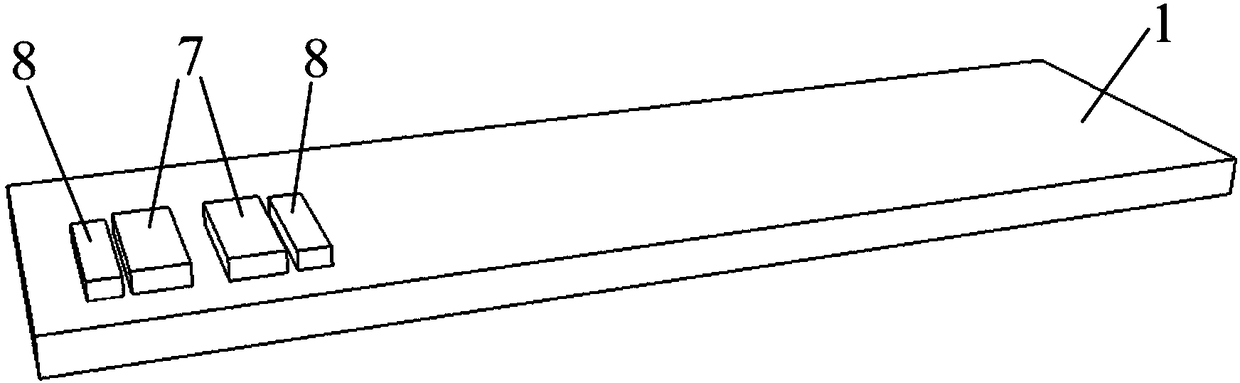

[0075] In the first step, a graphene-carbon nanotube composite structure microbubble generator and a carbon nanotube temperature sensor array are prepared on a glass substrate;

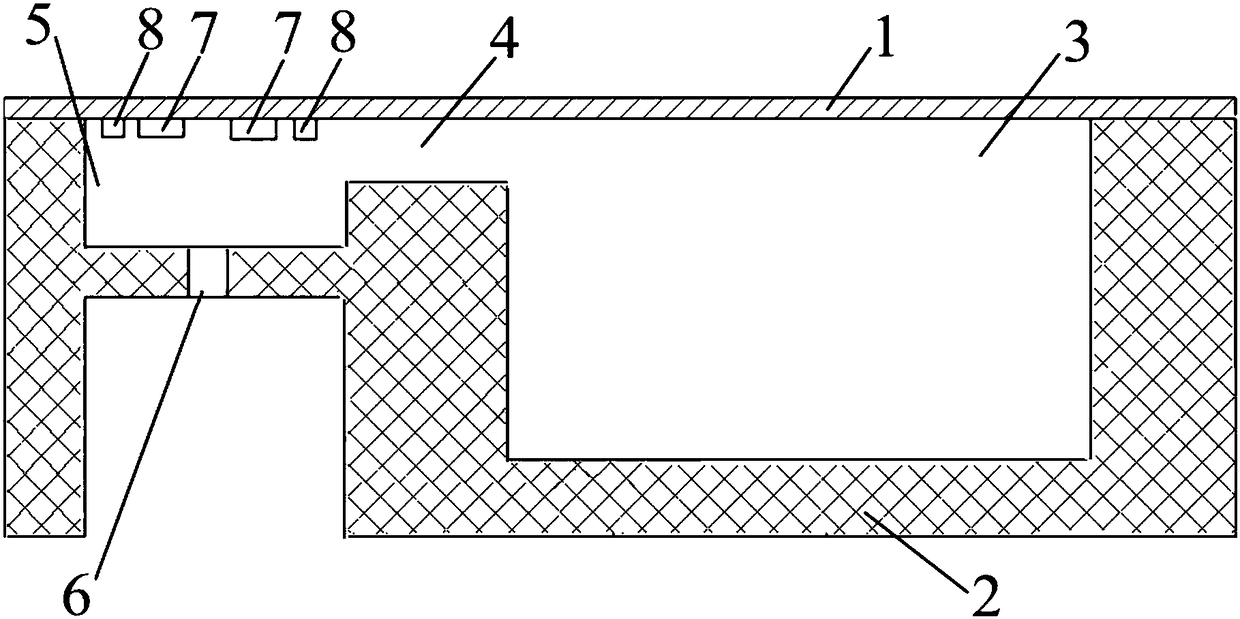

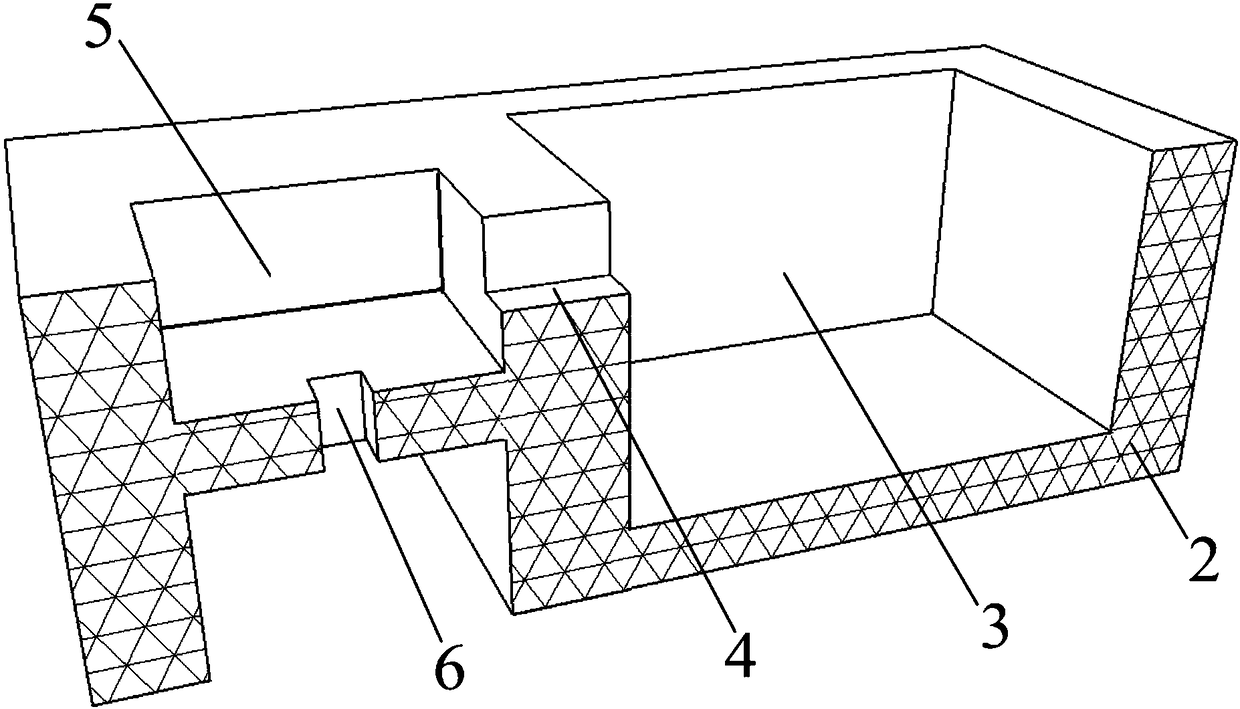

[0076]In the second step, the microfluidic structure is prepared on the silicon wafer by using the ICP process and the surface planarization process of PDMS (polydimethylsiloxane) to fill the deep groove; the microfluidic structure includes the main channel, the inkjet chamber, the ink inlet channels, nozzles, inkjet channels;

[0077] In the third step, the glass and silicon wafers are bonded using an anodic bonding process with graphene fragments as the intermediate layer. The bonding method is shown in Figures 9 and 10. The graphene fragments 9 are located between the glass substrate 1 and the silicon substrate 2. High pressure and high temperature are applied to the glass substrat...

Embodiment 1

[0110] (1) Using quartz glass as the substrate, the quartz glass is cleaned, and the graphene-carbon nanotube composite structure microbubble generator and carbon nanotube temperature sensor array are prepared on the quartz glass. The process is as follows:

[0111] (1.1) Magnetron sputtering is used to form a nickel film with a thickness of 100nm, and nickel electrodes are formed by using the existing stripping process; the distance between the nickel electrodes of the temperature sensor is 2 μm, and the width is 4 μm;

[0112] (1.2) The graphene grown by CVD on the copper foil is transferred to the glass substrate by the wet transfer process of spin-coated PMMA, and the graphene electrode of the microbubble generator is prepared through the RIE etching of photolithography and oxygen; the graphene electrode of the graphene electrode The pitch is 2 μm and the width is 4 μm;

[0113](1.3) Mix carbon nanotubes with absolute ethanol solvent at a ratio of 0.001mg / ml, and disperse ...

Embodiment 2

[0132] (1) Using Pyrex7740 type glass as the substrate, the glass is cleaned, and the microbubble generator and temperature sensor based on the graphene-carbon nanotube composite structure are prepared on the quartz glass, and the process is as follows:

[0133] (1.1) Magnetron sputtering is used to form a titanium film with a thickness of 200nm, and a titanium test electrode is formed by using the existing stripping process;

[0134] (1.2) Adopt the wet transfer process of spin-coated PMMA to transfer the graphene grown by CVD on the copper foil to the glass substrate, and prepare the graphene electrode of microbubble generator and temperature sensor through photolithography and RIE etching of oxygen; The pitch is 6 μm and the width is 5 μm;

[0135] (1.3) Mix the carbon nanotubes and absolute ethanol solvent at a ratio of 0.05 mg / ml, and disperse the carbon nanotubes evenly by ultrasound; apply an AC voltage of 1 MHz, 16 V between the titanium electrodes on the glass, and us...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com