High-performance straw fiber oil-absorbing material, as well as preparation method and application thereof

An oil-absorbing material, straw fiber technology, applied in chemical instruments and methods, other chemical processes, adsorption water/sewage treatment, etc., can solve the problems of low recycling performance, low saturated oil absorption capacity, poor oil-water selectivity, etc. Significant cost and environmental protection, high oil absorption performance, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0077] This example provides a method of using ethyl acetate as a solvent and palm wax as a hydrophobic agent to modify rice straw to obtain a rice straw fiber oil-absorbing material, and this example also provides an oil-absorbing material for the prepared rice straw fiber The oil and water absorption and oil holding performance of the material were tested:

[0078] Wherein, the preparation method of the rice straw fiber oil-absorbing material comprises the following steps:

[0079] (1) Preparation of hydrophobic agent solution: Take 0.5g of palm wax into a 500mL beaker, add 200mL of ethyl acetate, heat and dissolve in a constant temperature water bath at 80°C for 30min, and obtain a hydrophobic agent with a mass concentration of 0.0025g / ml solution.

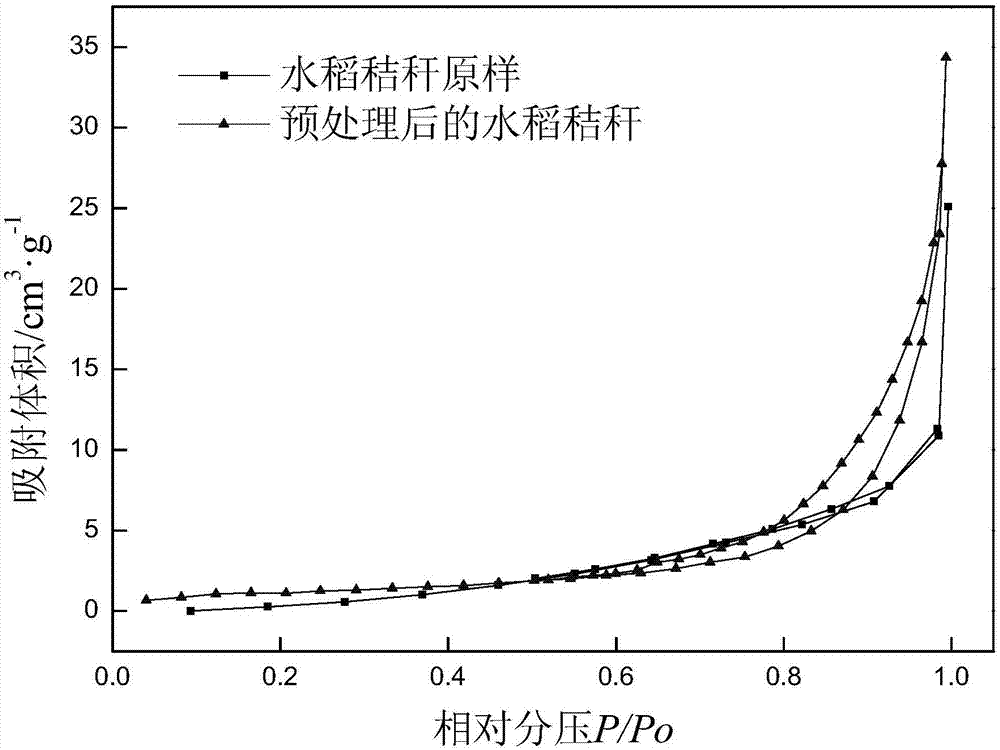

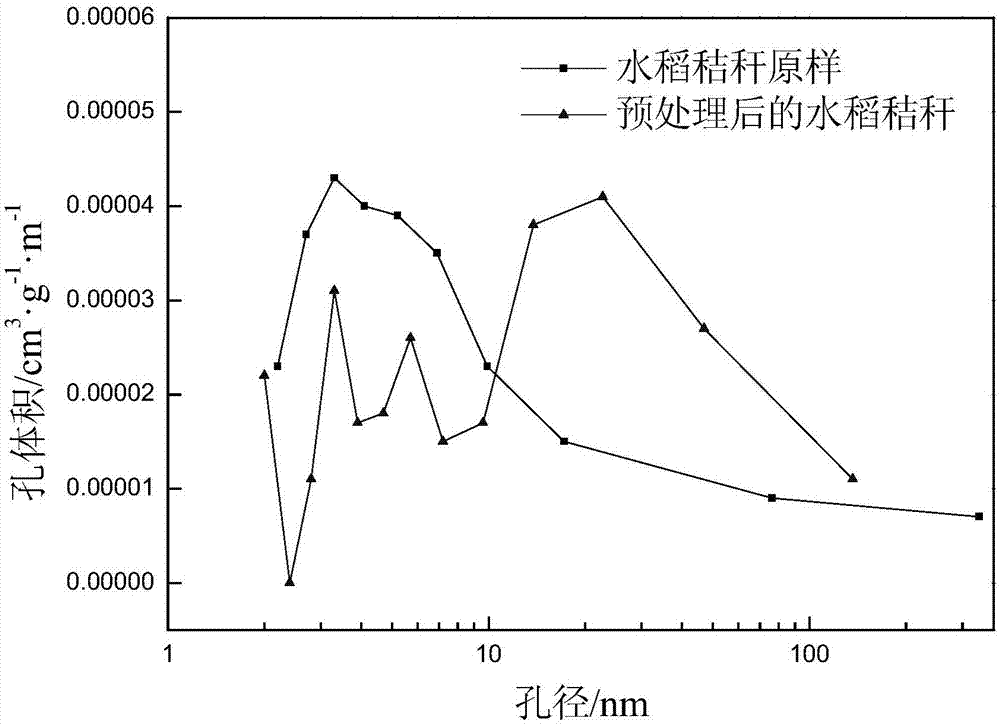

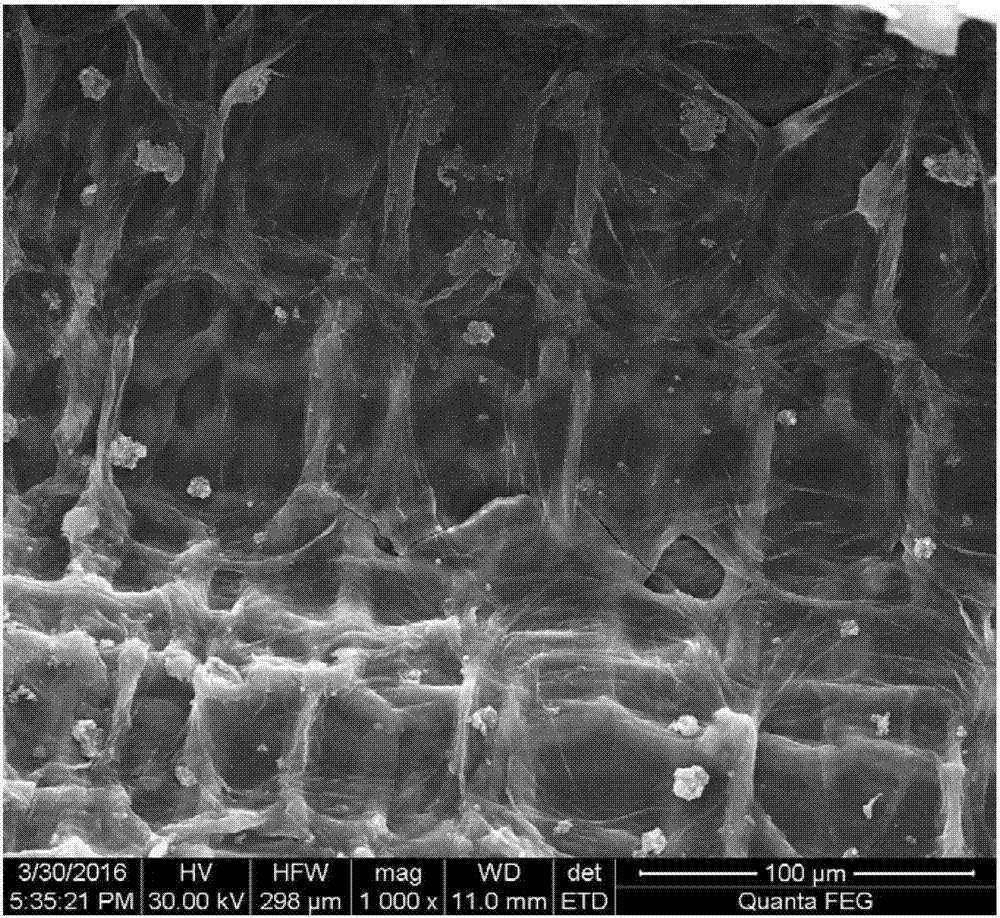

[0080] (2) Pretreatment of straw: Take 40g of rice straw powder (850μm-1cm) in the autoclave, add 800mL of deionized water, raise the temperature in the autoclave to 200°C, pretreat for 15min, and open it after cooling down an...

Embodiment 2

[0091] This example provides a method of using ethyl acetate as a solvent and paraffin as a hydrophobic agent to modify corn stalks to obtain a corn stalk fiber oil-absorbing material, and this example also provides the prepared corn stalk fiber oil-absorbing material The oil and water absorption and oil holding performance were tested:

[0092] Wherein, the preparation method of corn stalk fiber oil-absorbing material comprises the following steps:

[0093] (1) Preparation of hydrophobic agent solution: Put 1 g of paraffin into a 500 mL beaker, add 300 mL of ethyl acetate, heat and dissolve in a constant temperature water bath at 80°C for 30 min, and obtain a hydrophobic agent solution with a mass concentration of 0.0033 g / mL.

[0094] (2) Pretreatment of straw: Take 20g of corn stalk powder (250μm-850μm) in a high-pressure reactor, add 800mL of deionized water, raise the temperature in the reactor to 180°C, pretreat for 30min, and open it after cooling down and releasing the...

Embodiment 3

[0101] This example provides a method of using carbon tetrachloride as a solvent and palm wax as a hydrophobic agent to modify wheat straw to obtain an oil-absorbing material, and this example also provides an overview of the prepared wheat straw fiber oil-absorbing material. Oil absorption, water absorption and oil holding performance were tested:

[0102] (1) Preparation of hydrophobic agent solution: Take 0.8g of palm wax and put it into a 500mL beaker, add 100mL of carbon tetrachloride, heat and dissolve in a constant temperature water bath at 70°C for 20min, and obtain a hydrophobic agent with a mass concentration of 0.008g / mL agent solution.

[0103] (2) Pretreatment of straw: Take 30g of wheat straw powder (150μm-250μm) in a high-pressure reactor, add 600mL of deionized water, raise the temperature in the reactor to 210°C, pretreat for 15min, and open it after cooling down and releasing the pressure The reaction kettle was filtered and washed to obtain a solid filter r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com