Device and method for preparing copper-based catalyst by coprecipitation

A copper-based catalyst, co-precipitation technology, applied in chemical instruments and methods, catalyst activation/preparation, physical/chemical process catalysts, etc. problems such as optimal crystals to achieve the effect of improving accuracy, reducing uncertainty, and reducing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

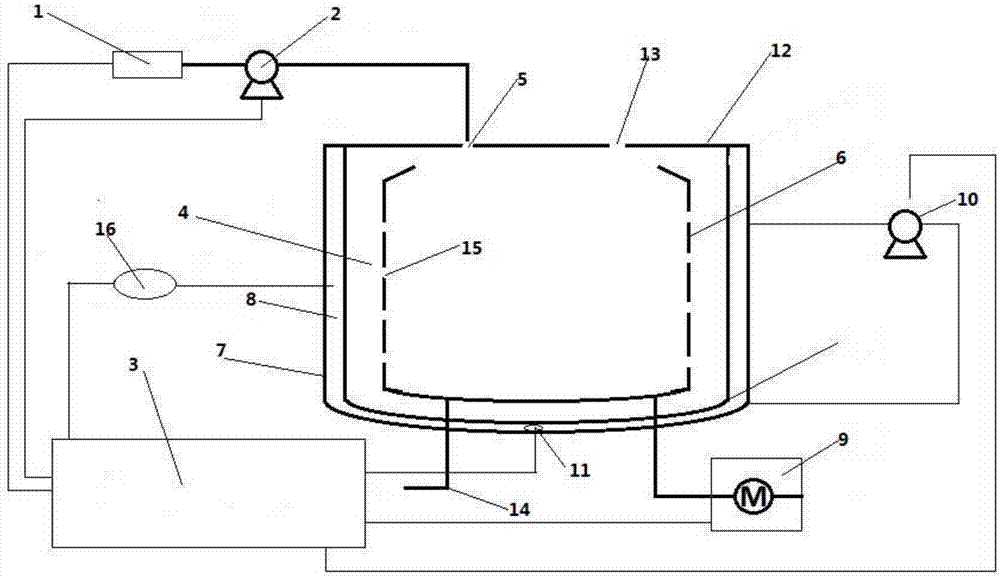

[0045] Preparation of methanol-steam recombination catalyst for hydrogen production: Weigh appropriate amount of copper nitrate, aluminum nitrate and zinc nitrate and dissolve in 2L of deionized water, and weigh appropriate amount of sodium carbonate and dissolve in 2L of deionized water. The obtained salt and alkali are dissolved in a raw material liquid preheater for preheating, then fed into a reaction kettle through a feed pump for reaction and aging. After aging, open the drain valve at the bottom, adjust the rotation frequency of the drum, and at the same time continuously add deionized water through the water inlet of the kettle cover, and the sodium ions and nitrate ions in the reaction product will be discharged through the drain. After washing, the filter cake obtained by centrifugal drying is evenly pasted on the filter cloth of the drum, and the temperature of the heat transfer oil in the jacket is adjusted to dry the filter cake to remove its physical moisture. Th...

Embodiment 2

[0047] Catalytic cracking of methanol to prepare carbon monoxide catalyst: Weigh an appropriate amount of copper nitrate, zinc nitrate and nickel nitrate and dissolve them in 1.8L of water, and weigh an appropriate amount of sodium carbonate and dissolve them in 2L of water. The obtained salt and alkali are dissolved in a raw material liquid preheater for preheating, then fed into a reaction kettle through a feed pump for reaction and aging. After aging, open the drain valve at the bottom, adjust the rotation frequency of the drum, and at the same time continuously add deionized water through the water inlet of the kettle cover, and the sodium ions and nitrate ions in the reaction product will be discharged through the drain. After washing, the filter cake obtained by centrifugal drying is evenly pasted on the filter cloth of the drum, and the temperature of the heat transfer oil in the jacket is adjusted to dry the filter cake to remove its physical moisture. The desired hydr...

Embodiment 3

[0049] Preparation of low-carbon mixed alcohol catalyst for synthesis gas: Weigh an appropriate amount of zinc nitrate, aluminum nitrate, copper nitrate and cobalt nitrate and dissolve them in 2.5L of water, and weigh an appropriate amount of potassium carbonate and dissolve them in 2.5L of water. The obtained salt and alkali are dissolved in a raw material liquid preheater for preheating, and added to a reaction kettle for reaction. After the one-step reaction and aging is completed, the preheated second-step raw material solution is added to the reaction kettle for reaction and aging. After aging, open the drain valve at the bottom, adjust the rotating frequency of the drum, and at the same time continuously add deionized water through the water inlet of the kettle cover, and the potassium ions and nitrate ions in the reaction product will be discharged through the drain. After washing, the filter cake obtained by centrifugal drying is evenly pasted on the filter cloth on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com