Carbon fluoride and preparation method and application thereof

A carbon fluoride, the technology of carbon fluoride, which is applied in electrical components, battery electrodes, non-aqueous electrolyte batteries, etc., can solve the problems of limited industrialization development, poor storage performance, unstable carbon fluoride material structure, etc. Large market application prospect, simple preparation method effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

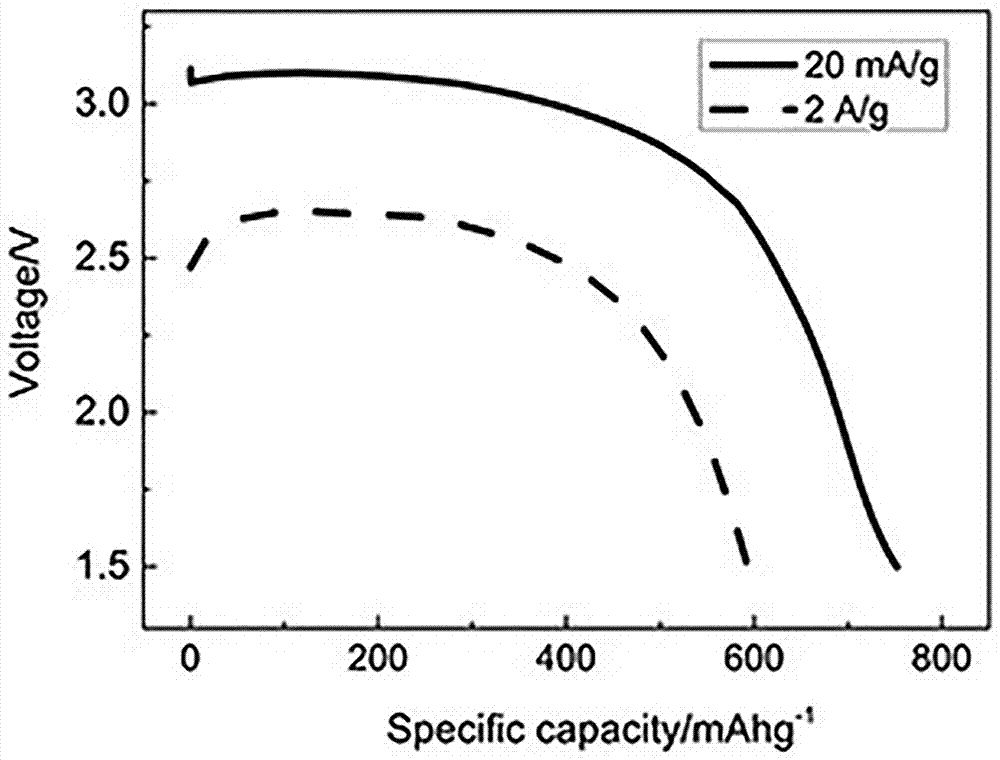

Embodiment 1

[0022] (1) Put 10g of carbon powder into the fluorination equipment, the C content is 80%, the N content is 8%, the H content is 5%, and the O content is 7%;

[0023] (2) The fluorination equipment was evacuated to make the vacuum degree reach -0.01 MPa, the fluorinated gas nitrogen trifluoride was introduced, the pressure was maintained at 200 kPa, and the reaction was carried out at 450 °C for 12 h to obtain 13.9 g of carbon fluoride. , in which the C content is 57.6 %, the F content is 42.4 %, and the discharge voltage plateau is 3.1 V (vs. Li + / Li).

Embodiment 2

[0025] (1) Put 10g of carbon powder into the fluorination equipment, the C content is 85%, the N content is 8%, the H content is 4%, and the O content is 3%;

[0026] (2) The fluorination equipment was evacuated to make the vacuum degree reach -0.01 MPa, the fluorinated gas nitrogen trifluoride was introduced, the pressure was kept at 300 kPa, and the reaction was carried out at 550 °C for 16 h to obtain 17.4 g of carbon fluoride. , in which the C content is 48.8%, the F content is 51.2%, and the discharge voltage plateau is 3.0 V (vs. Li + / Li).

Embodiment 3

[0028] (1) Put 10g of carbon powder into the fluorination equipment, the C content is 94%, the N content is 4%, and the H content is 2%;

[0029] (2) The fluorination equipment was evacuated to make the vacuum degree reach -0.01 MPa, the fluorinated gas nitrogen trifluoride was introduced, the pressure was maintained at 400 kPa, and the reaction was carried out at 600 °C for 16 h to obtain 21.3 g of carbon fluoride. , in which the C content is 44.1%, the F content is 55.9%, and the discharge voltage plateau is 3.0 V (vs. Li + / Li).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com