Photovoltaic materials and their preparation methods and applications

A photovoltaic material and atomic technology, applied in the field of solar cells, can solve problems such as increasing efficiency, high cost, and reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

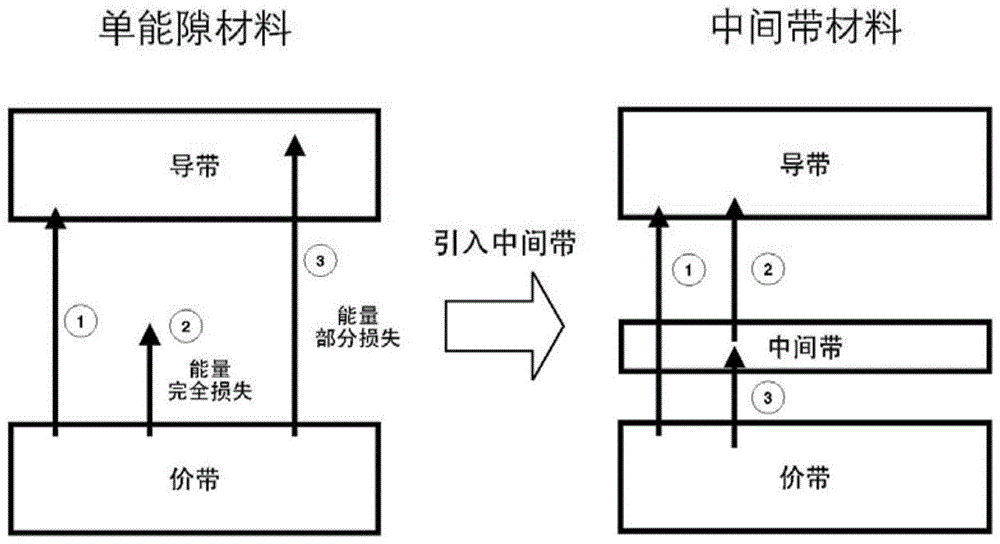

[0024] In the preparation process of the above-mentioned photovoltaic material, different chemical ratios are used, which will produce different impurity phases in the semiconductor material. Specific impurity phases can be produced by precise stoichiometry. In order to manufacture special functional materials. According to calculations, when Al and Se have an accurate ratio of 1:2, the doped P will replace Al and Se atoms at the same time, and the substitution of P for Al and Se will produce ions with different electrical properties. The positions of Al and Se tend to be close to each other to form stable substitution pairs, which will help the formation of high-concentration doped materials. This substitution has the effect of forming a new intermediate band in the original energy gap. The density of states in the middle band is determined by the doping concentration of P. In particular, a more reasonable doping concentration is between 5% and 20%.

[0025] Figure 4-6 ...

Embodiment 1

[0045] see Figure 8 , Figure 8 It is a schematic diagram of the structure of the vapor deposition sample equipment. Figure 7 11, 12, 13 and 14 are heating source furnaces for Cu, Al, Se and doping element X respectively. The shutter 20 is used to close the source port in time when the evaporation ends. Molecular beams formed when Cu, Al, Se and dopant elements are heated and evaporated. The substrate 30 is provided between the heater 40 and the heat source furnaces 11 , 12 , 13 , and 14 .

[0046] First, put the prepared soda-lime glass coated with 1 μm thick Mo as the substrate on the sample holder, close the sampling window, and use the co-evaporation method to simultaneously heat the source furnace of Cu, Al, P, and Se in the MBE chamber The target material in the present invention obtains a photovoltaic material with an atomic ratio of Cu:Al:P:Se=1.0:0.9:0.2:1.9. Among them, the temperature of the substrate is 400°C, and the temperatures of the source furnaces of C...

Embodiment 2

[0048] Put the prepared soda-lime glass coated with Mo with a thickness of 1 μm as the substrate on the sample holder, close the sampling window, and use the co-evaporation method to simultaneously heat the source furnaces of Cu, Al, As, and Se in the MBE chamber, A photovoltaic material with an atomic ratio of Cu:Al:As:Se=1.0:0.95:0.1:1.95 is obtained. Among them, the temperature of the substrate is 420°C, and the temperatures of the source furnaces of Cu, Al, As, and Se are 1260°C, 710°C, 800°C, and 280°C, respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com