Electroless tin plating formula for printed circuit board

A printed circuit board, chemical tin plating technology, applied in liquid chemical plating, metal material coating process, coating and other directions, can solve the problems of easy penetration plating, chemical nickel gold nickel corrosion, high storage conditions, etc. The coating is flat and dense, reducing adverse effects and excellent compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] Stannous ion: 10g / L;

[0055] Thiourea: 70g / L;

[0056] Methanesulfonic acid: 70g / L;

[0057] Citric acid: 30g / L;

[0058] Tetrasodium iminodisuccinate: 50g / L;

[0059] Carbohydrazide: 30g / L;

[0060] Sodium dodecylbenzenesulfonate: 10mg / L;

[0061] Bismuth acetate: 0.15g / L;

[0062] Polyamino polyether methylene phosphonic acid: 20g / L;

[0063] The bath temperature is 65°C; the time is 15 minutes;

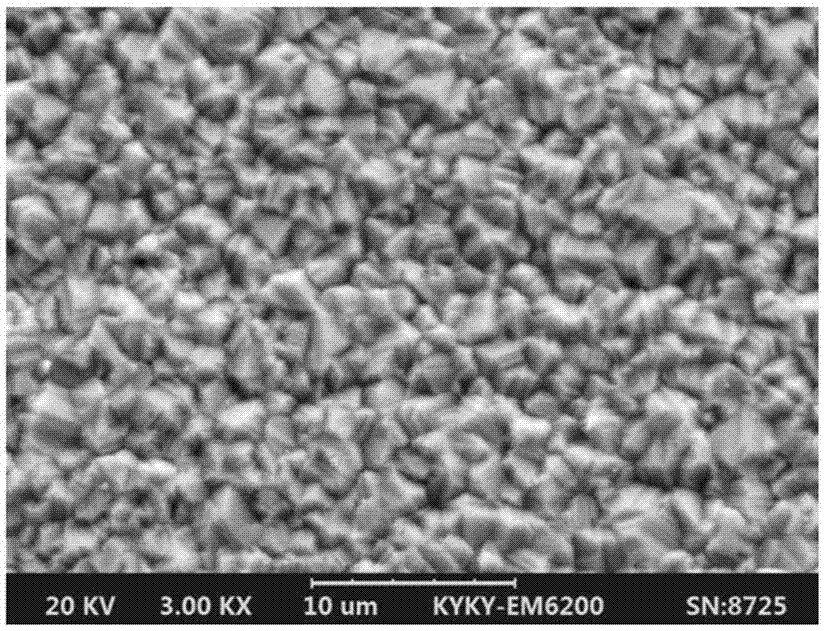

[0064] The thickness of the obtained coating is 0.84 μm, and the surface morphology of the coating is as follows figure 1 shown, from figure 1 It can be seen from the figure that the industry generally requires the thickness of the electroless tin coating to be above 0.8 microns. The thickness of the coating under this formula and parameter conditions meets the requirements of the industry, and the crystallization of the coating is clear and dense.

Embodiment 2

[0066] Stannous ion: 30g / L;

[0067] Thiourea: 130g / L;

[0068] Methanesulfonic acid: 30g / L;

[0069] Citric acid: 60g / L;

[0070] Tetrasodium iminodisuccinate: 20g / L;

[0071] Carbohydrazide: 10g / L;

[0072] Sodium dodecylbenzenesulfonate: 50mg / L;

[0073] Bismuth acetate: 0.05g / L;

[0074] Polyamino polyether methylene phosphonic acid: 40g / L;

[0075] The bath temperature is 70°C; the time is 15 minutes;

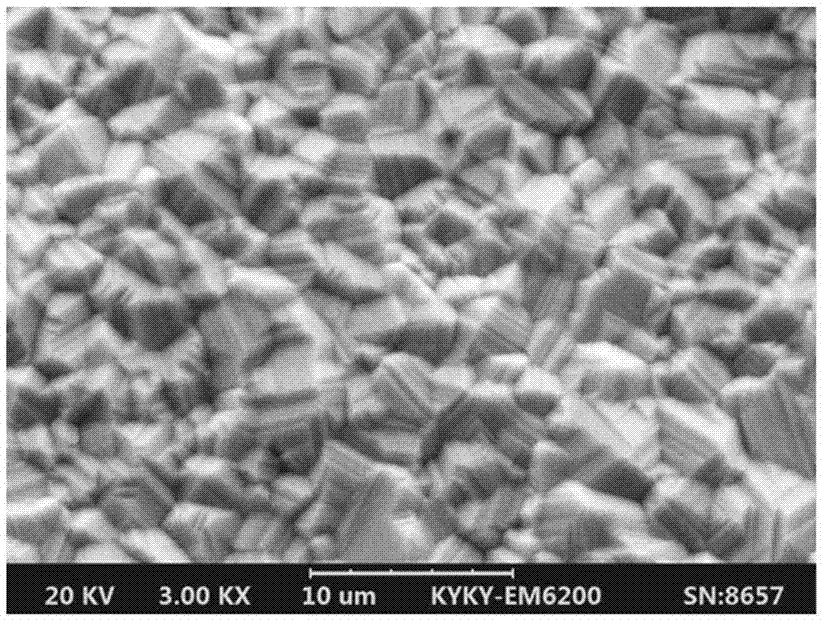

[0076] The thickness of the obtained coating is 1.34 μm, and the surface morphology of the coating is as follows figure 2 shown, from figure 2 It can be seen from the figure that the industry generally requires the thickness of the electroless tin coating to be above 0.8 microns, and the thickness of the coating under this formula and parameter conditions meets the requirements of the industry, and the crystallization of the coating is clear and dense.

Embodiment 3

[0078] Stannous ion: 20g / L;

[0079] Thiourea: 100g / L;

[0080] Methanesulfonic acid: 45g / L;

[0081] Citric acid: 50g / L;

[0082] Tetrasodium iminodisuccinate: 35g / L;

[0083] Carbohydrazide: 15g / L;

[0084] Sodium lauryl sulfate: 45mg / L;

[0085] Bismuth acetate: 0.1g / L;

[0086] Polyamino polyether methylene phosphonic acid: 30g / L;

[0087] The bath temperature is 75°C; the time is 15 minutes;

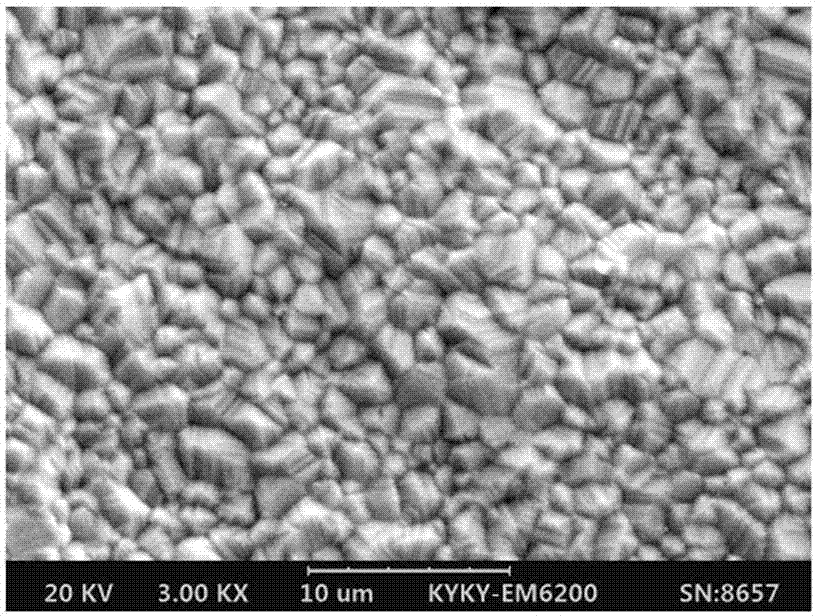

[0088] The thickness of the coating is 1.28 μm, and the surface morphology of the coating is as follows image 3 shown, from image 3 It can be seen from the figure that the industry generally requires the thickness of the electroless tin coating to be above 0.8 microns. The thickness of the coating under this formula and parameter conditions meets the requirements of the industry, and the crystallization of the coating is clear and dense.

[0089] As a comparative example: use a commercially available chemical tin plating solution to carry out chemical tin plating, the tem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com