Automatic processing equipment and processing method for carbon fiber tube

A carbon fiber tube and processing equipment technology, which is applied in metal processing equipment, lighting and heating equipment, grinding/polishing equipment, etc., can solve the problems of not being suitable for mass production, inconvenient daily maintenance, and increasing production costs, and achieves convenience The effects of daily maintenance and repair, shortening the production cycle and improving the production progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

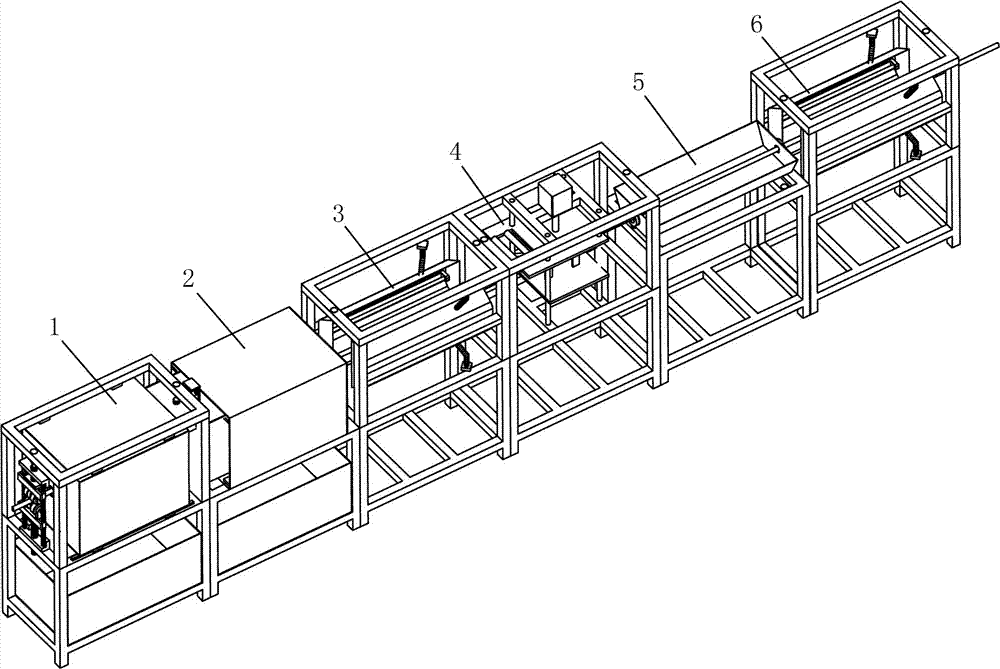

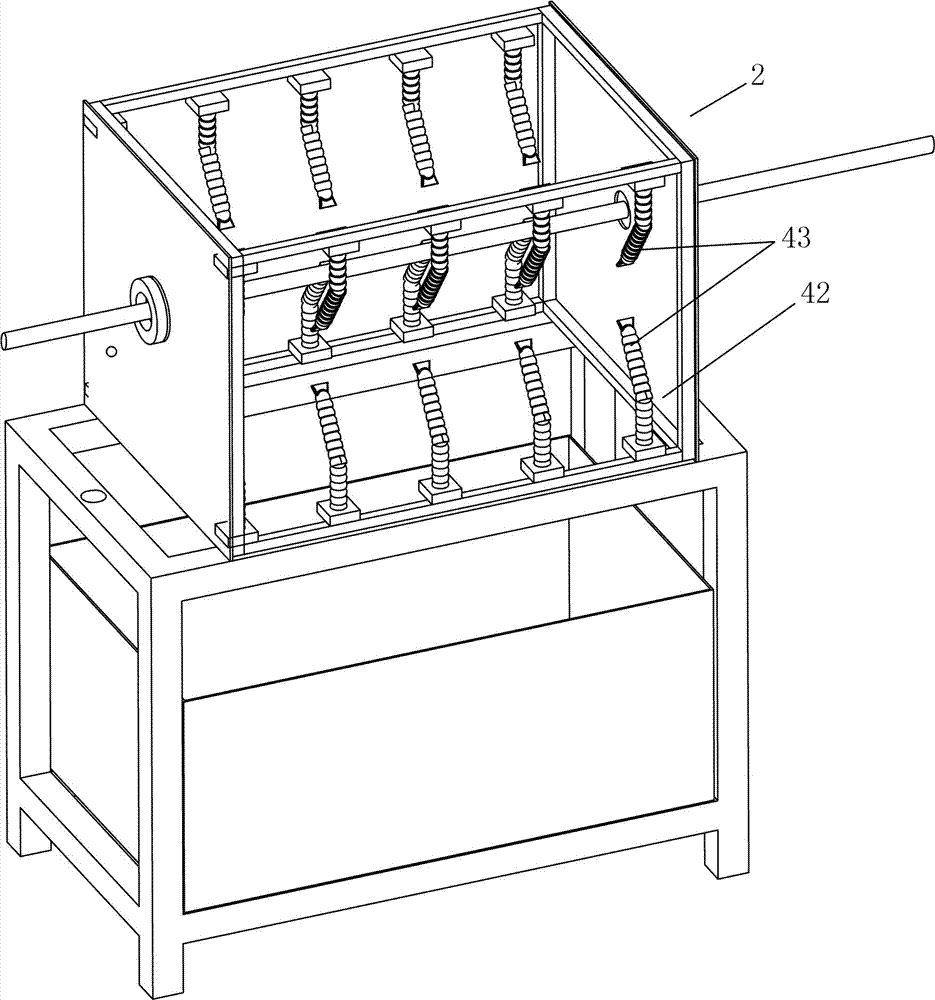

[0036] like Figure 1-10 As shown, an automatic processing equipment for carbon fiber tubes, including a polishing device 1, a washing device 2, a first drying device 3, a printing device 4, a gluing device 5 and The second drying device 6;

[0037] Described grinding device 1 comprises the feeding mechanism 7 that is arranged on both sides of frame respectively and the positioning grinding mechanism 8 that is arranged between described feeding mechanism 7, and described positioning grinding mechanism 8 is made of several grinding gears that are arranged coaxially and at intervals. Composed of components 9, the grinding components 9 are provided with a positioning plate 10, the two sides of the positioning plate 10 are respectively provided with an adjustment group 11 and a grinding group 12, and the grinding group 12 is provided with several The roller 13 on the positioning plate 10, the roller 13 is wound with a slidable grinding belt 14, and the accommodating cavity 15 for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com