T-shaped aluminum soldering machine

The technology of welding machine and automatic welding machine is applied in the fields of aluminum alloy welding and aluminum alloy hull construction to achieve the effects of reducing labor intensity, simple structure and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

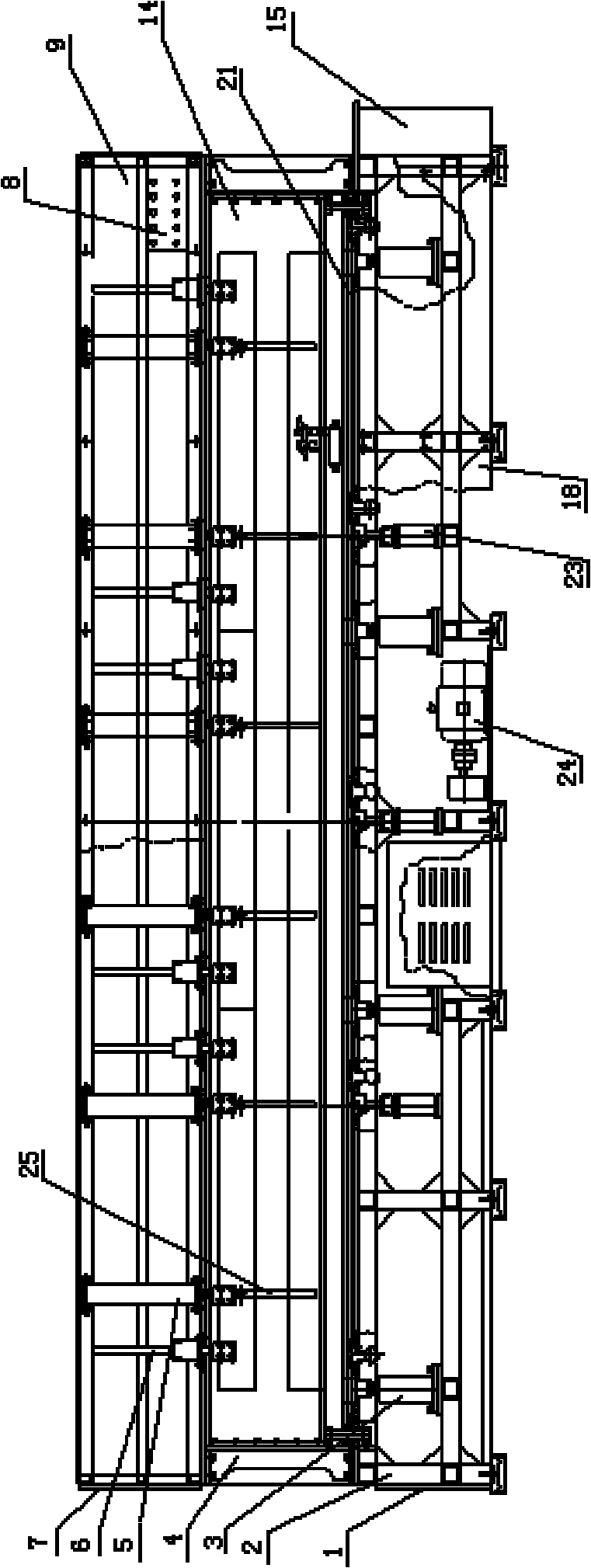

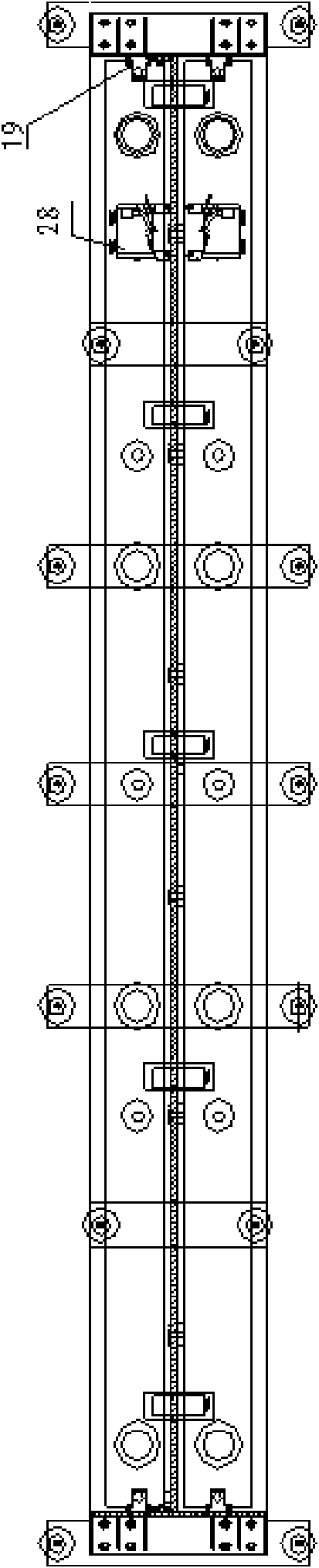

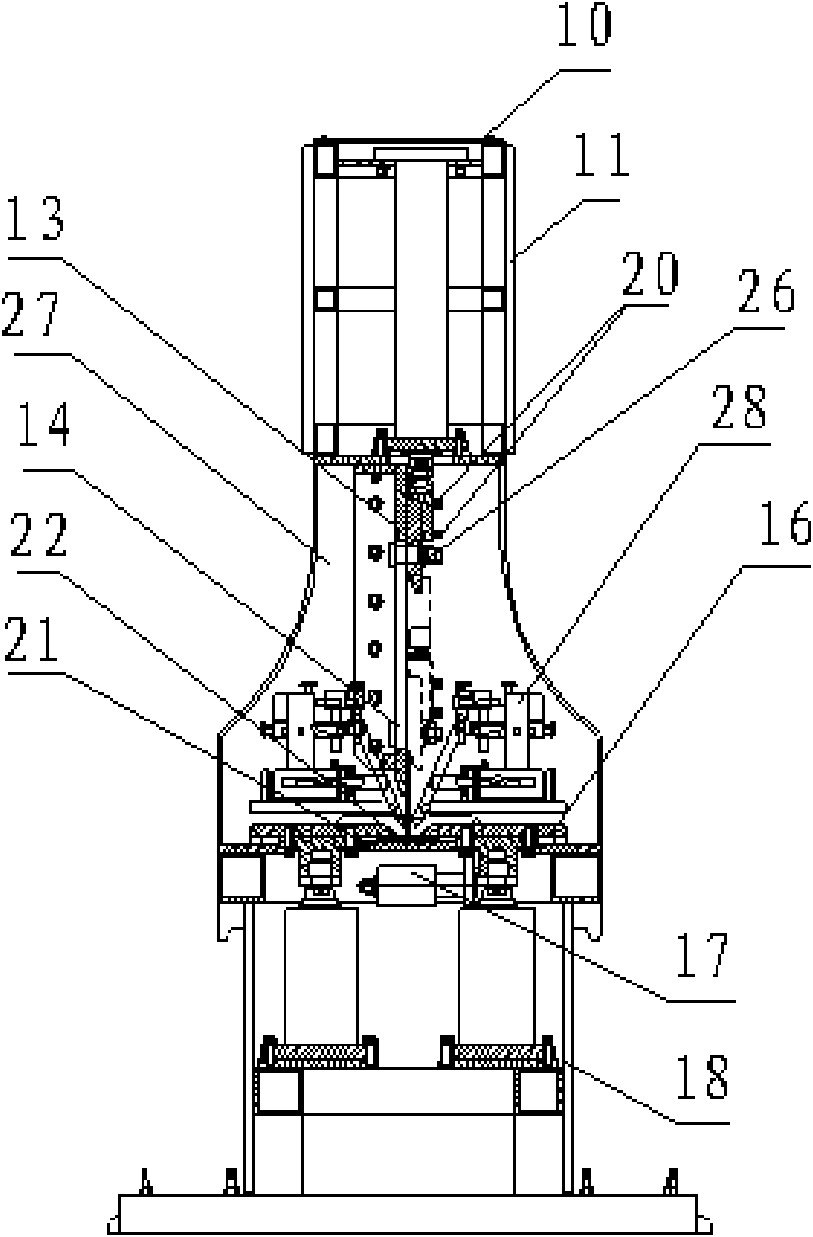

[0017] like figure 1 As shown, the lower frame 2 and the upper frame 9 are rectangular frame structures welded by square steel, the lower frame 2 is fixedly installed on the horizontal plane through the base, and the two are fixedly connected by bolts. A workbench panel 21 is installed on the lower frame 2, and the workbench panel 21 is a ridge shape, and the anti-deformation gap is reserved for the panel of T-shaped aluminum. Both ends of the lower frame 2 cover the end cover plate 1 of the lower frame, and the side covers the side cover plate 18 of the lower frame. Hydraulic system 24, the first oil cylinder 5, and the first oil cylinder 5 are connected to the hydraulic system 24 on the lower frame 2 under the workbench panel 21, and the first oil cylinder 5 piston rod heads are connected to the lower pressing plate 16, as image 3 shown. combined a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com