Material bonding machine

A bonding machine and material technology, which is applied in the field of pressing equipment, can solve problems such as slow production speed, poor flatness, and material waves, and achieve the effects of reducing the number of staff, reducing production costs, and reducing labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific embodiment of the present invention is described in detail below in conjunction with accompanying drawing:

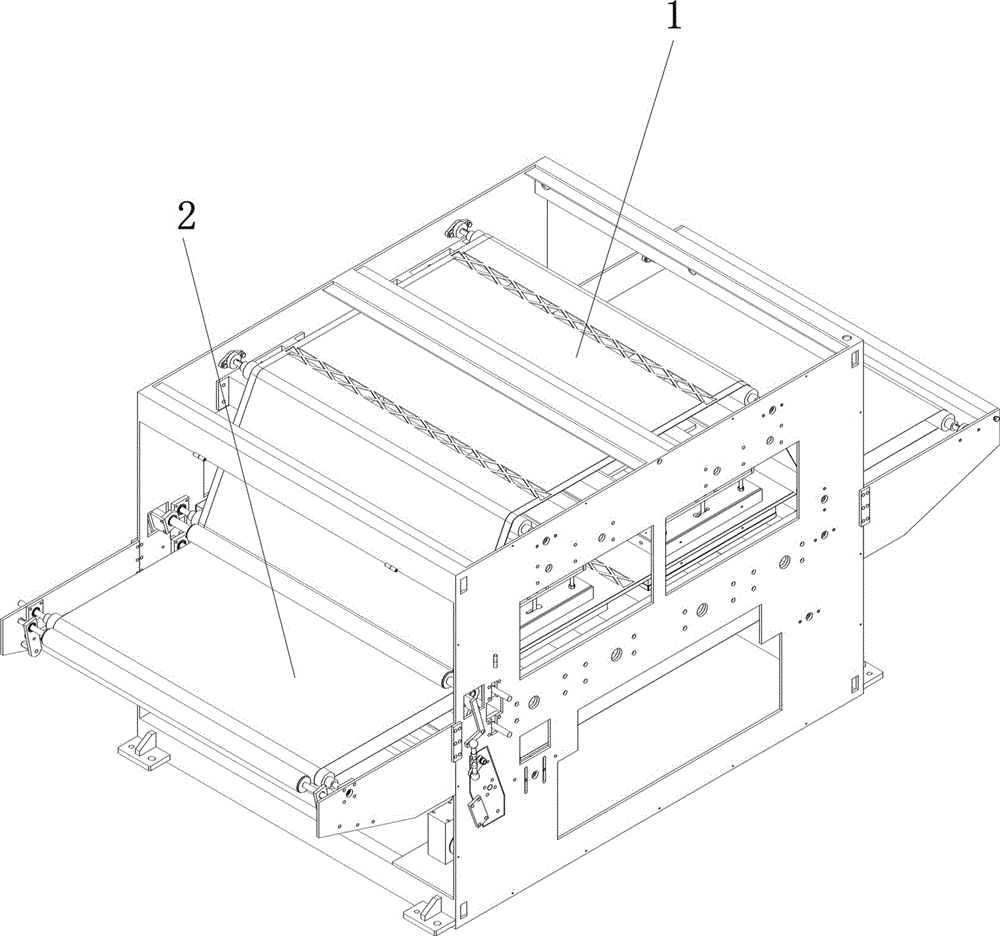

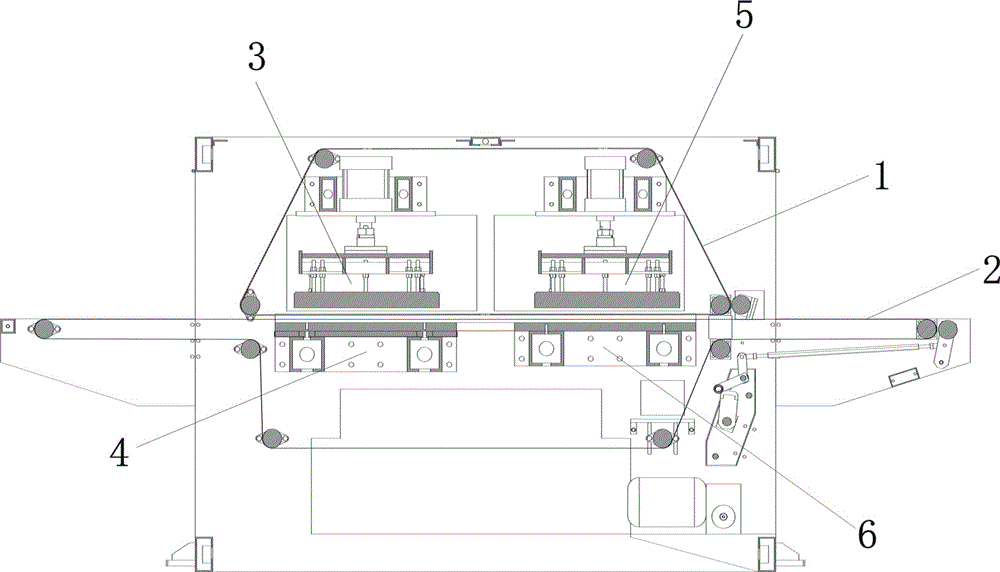

[0017] Referring to Fig. 1 and Fig. 2, the material bonding machine of the present specific embodiment comprises upper conveyer belt 1, lower conveyer belt 2 and thermal upper formwork 3, thermal lower formwork 4 and cold upper formwork 5, cold lower formwork 6, by upper Conveyor belt 1 and lower conveyor belt 2 realize pinching of materials, hot upper template 3 and cold upper template 5 are arranged on upper conveyor belt 1, hot lower template 4 and cold lower template 6 are arranged on lower conveyor belt 2, and the hot upper template Template 3 and hot lower template 4 heat press the material through upper conveyor belt 1 and lower conveyor belt 2 respectively, and then the cold upper template 5 and cold lower template 6 pass through upper conveyor belt 1 and lower conveyor belt 2 respectively for hot pressing The finished material is cooled, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com