An epoxy bracket for installing a drawer-type power module

A power module, drawer-type technology, applied in the field of brackets, to achieve the effects of small size, rapid protection and energy release, and convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

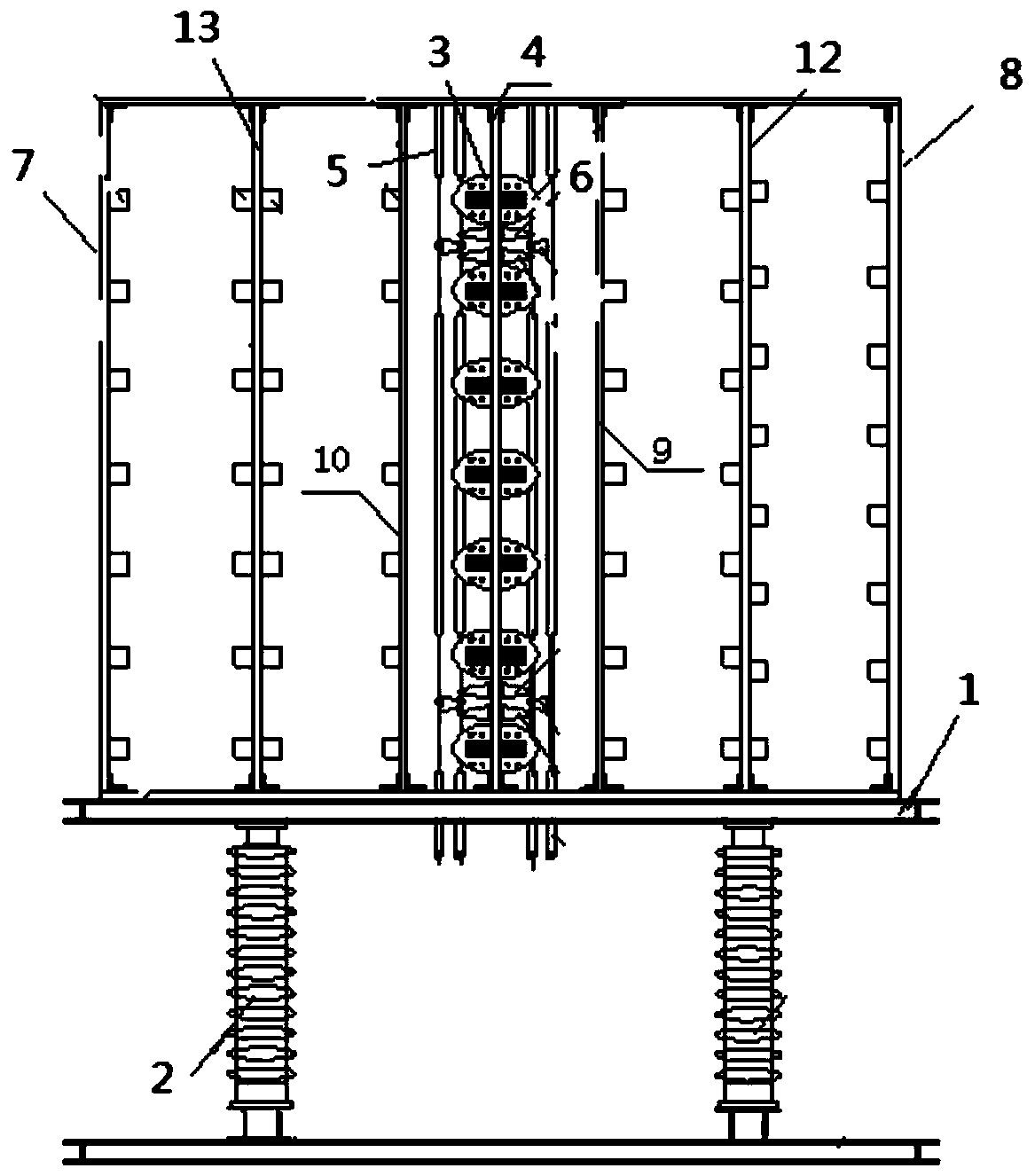

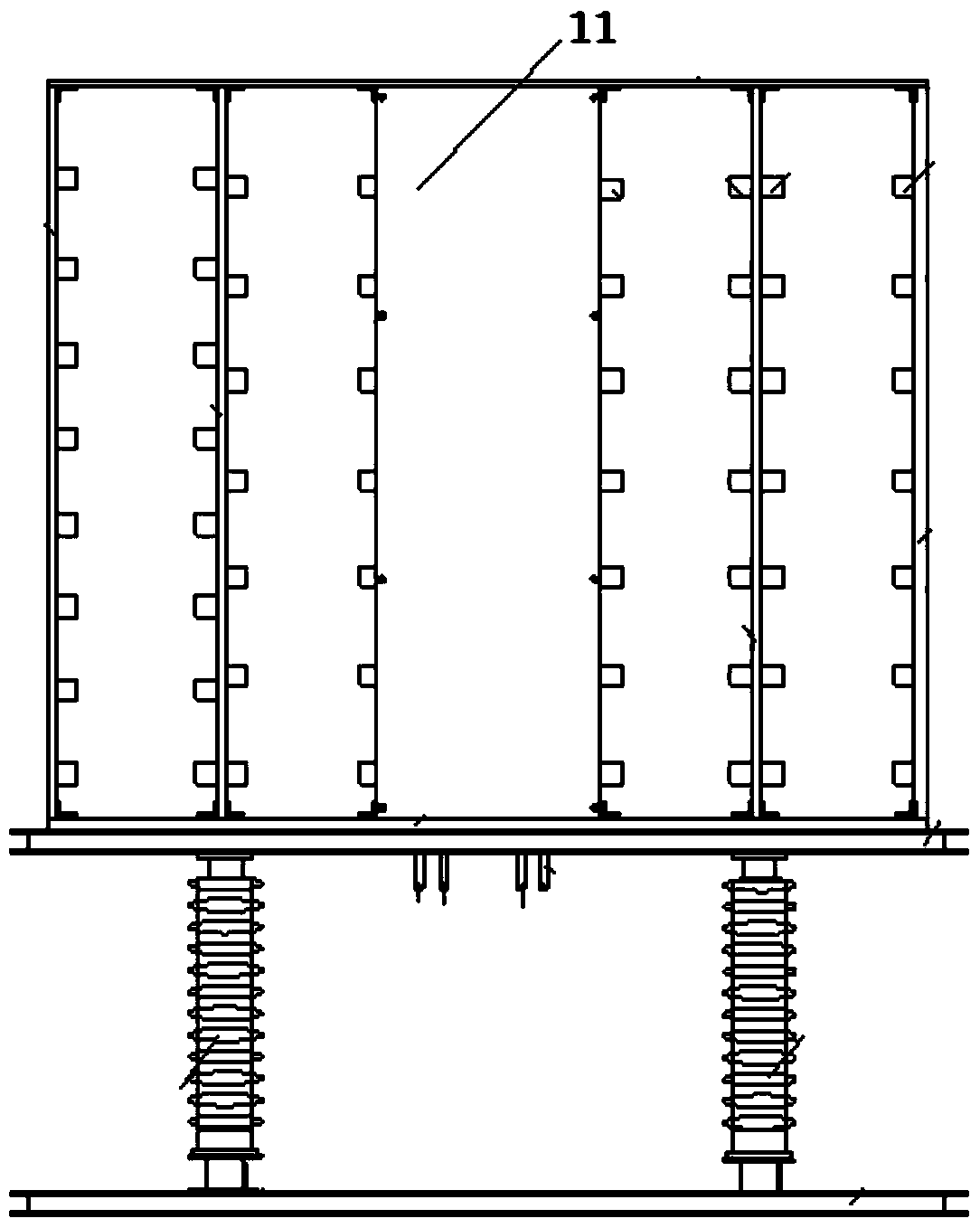

[0012] An epoxy bracket for installing a drawer-type power module, including a square casing 1 composed of epoxy boards, and a high-voltage porcelain bottle 2 is installed on the lower surface of the casing 1, and several epoxy boards are installed vertically inside the casing 1, including epoxy Board A4, Epoxy Board G7, Epoxy Board H8, Epoxy Board B9, Epoxy Board C10, Epoxy Board D11, Epoxy Board E12, Epoxy Board F13, located on the epoxy board A4 in the center of the shell 1 Install the transformer 3, a total of multiple transformers are installed on the epoxy board A4 located in the center of the shell 1, the copper strip 5 is installed on both sides of the epoxy board A4 through the insulating support 6, the transformer 3 is powered by the copper strip 5; the epoxy Epoxy strips are installed on board B9, epoxy board C10, epoxy board E12, epoxy board F13, left and right epoxy boards G7 and epoxy board H8 of shell 1, and power modules can be installed on the epoxy boards.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com