Three-phase amorphous inductor

An amorphous, three-phase technology, used in inductors, fixed inductors, fixed signal inductors, etc., can solve the problem that the product does not have high saturation magnetic induction intensity, cannot be applied to resist large current and strong interference, and cannot accurately control the insulation distance. and other problems, to achieve the effects of excellent temperature stability and frequency characteristics, low loss and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Specific embodiments of the present invention will be described below.

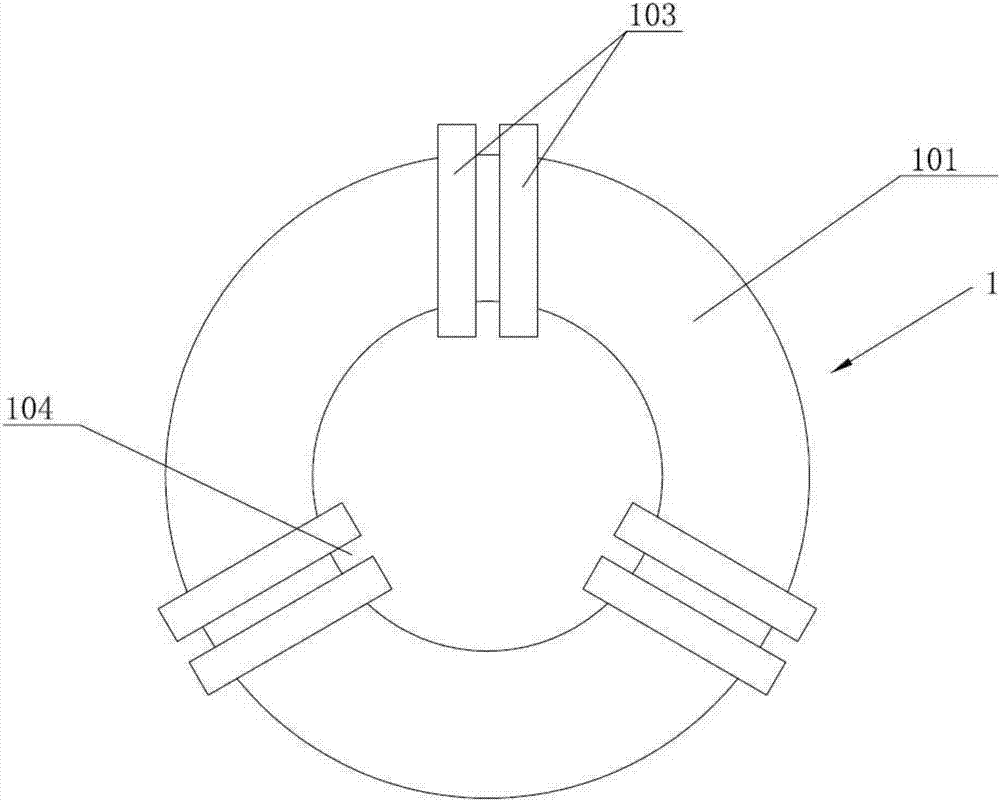

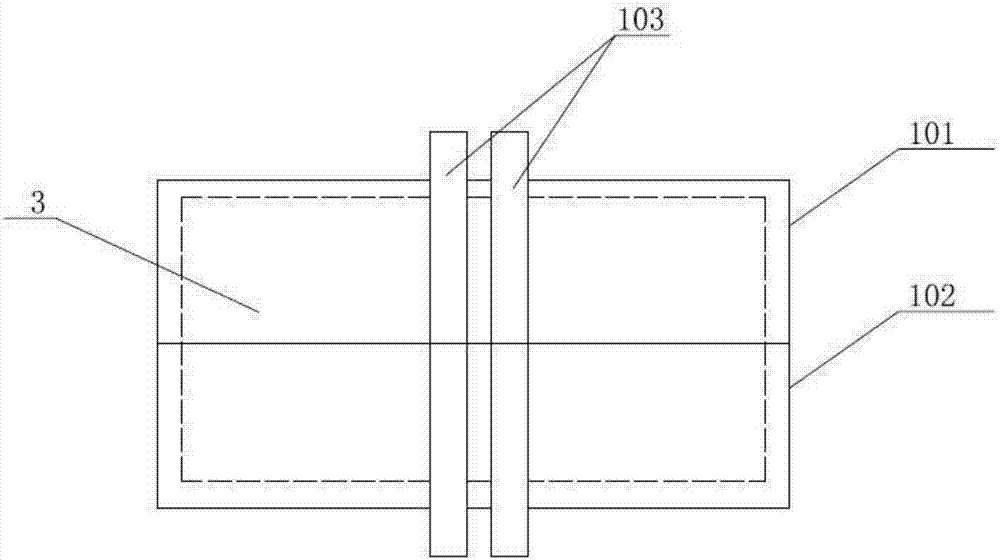

[0027] Such as figure 1 , figure 2 and Figure 6 As shown, the three-phase amorphous inductor is composed of a base 2 and a shell component 1 that cooperate with each other;

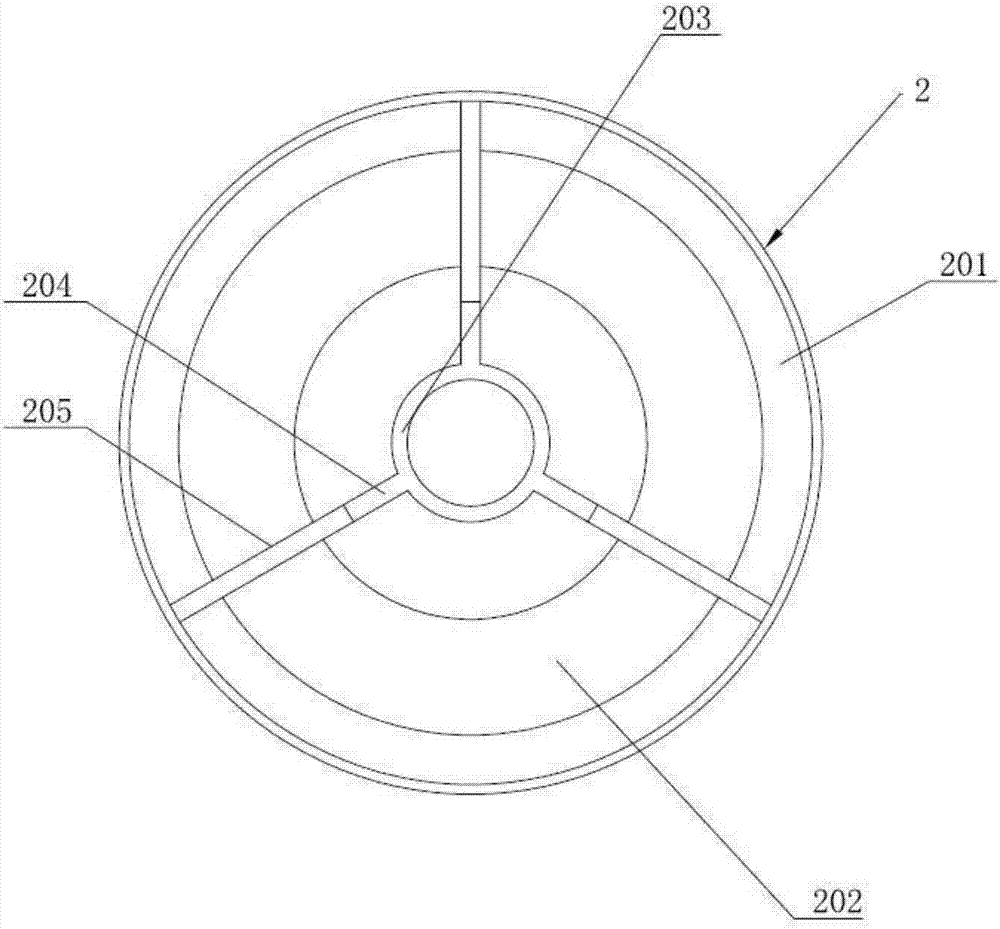

[0028] Such as figure 2 As shown, the specific structure of the base 2 is as follows:

[0029] It includes a seat body 201, a second positioning groove 202 for fitting the shell assembly 1 is provided on the seat body 201 along the circumferential direction, a flange 203 is formed extending from the center of the seat body 201, and at least extends outward along the outer periphery of the flange 203 Two fixing plates 204 are formed, and each fixing plate 204 is connected with the flange 203 to form an integral body, as Figure 5 As shown, the outside of each fixing plate 204 also extends outward along the horizontal direction to form a positioning bar 205, and each positioning bar 205 is connected with the fixing plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com