System and method for on-line heat loss test of groove type high temperature evacuated collector tubes

A technology of vacuum heat collecting tube and testing system, which is applied in the direction of liquid tightness measurement using liquid/vacuum degree, testing of fluid tightness, testing of machine/structural components, etc., to shorten detection time, small vacuum drift of leak rate, The effect of easy detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

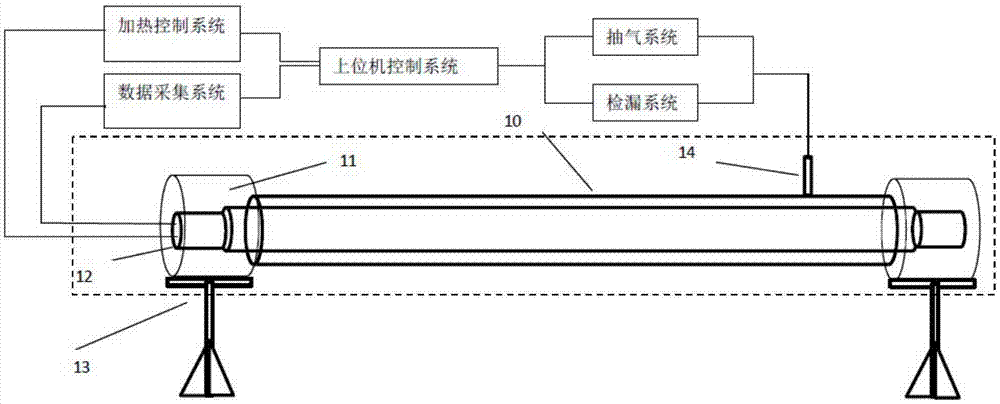

[0044] refer to figure 1 As shown, the on-line heat loss testing system of the trough-type high-temperature vacuum heat collecting tube of the present invention mainly includes an air extraction system, a leak detection system, a uniform temperature heating system, a heating control system, a data acquisition system and a host computer control system.

[0045] Described uniform temperature heating system (see figure 1 The dotted frame part in ) is used for heating the measured tube 10, and in this embodiment, the heater is composed of a heating rod and a uniform temperature copper tube.

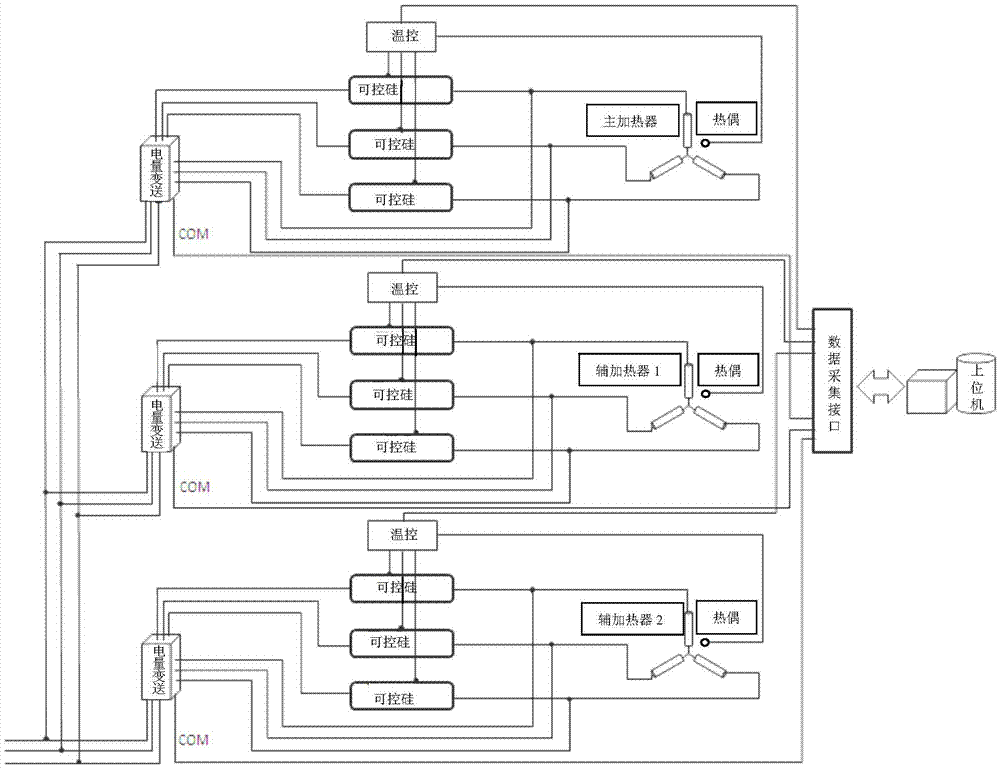

[0046] The heating control system includes power transmitters, temperature controllers and inspection instruments, circuit breakers with leakage protection, silicon controlled rectifiers, lead wires, etc., which can be set independently in the form of cabinets, and are used to control the uniform temperature heating system. Heating state implementation control, see image 3 As shown, its wo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com