The method of using the assembled tire frame of the ladder column integrated steel cylindrical revetment structure

An integrated, steel cylinder technology, applied in underwater structures, infrastructure engineering, construction, etc., can solve the problems of tooling structure disassembly, inconvenient hoisting, small operation space of construction platform, unfavorable equipment transportation and use, etc. The overall adaptability is strong, the construction space is large, and the operation is convenient.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in detail below with reference to the drawings and specific embodiments.

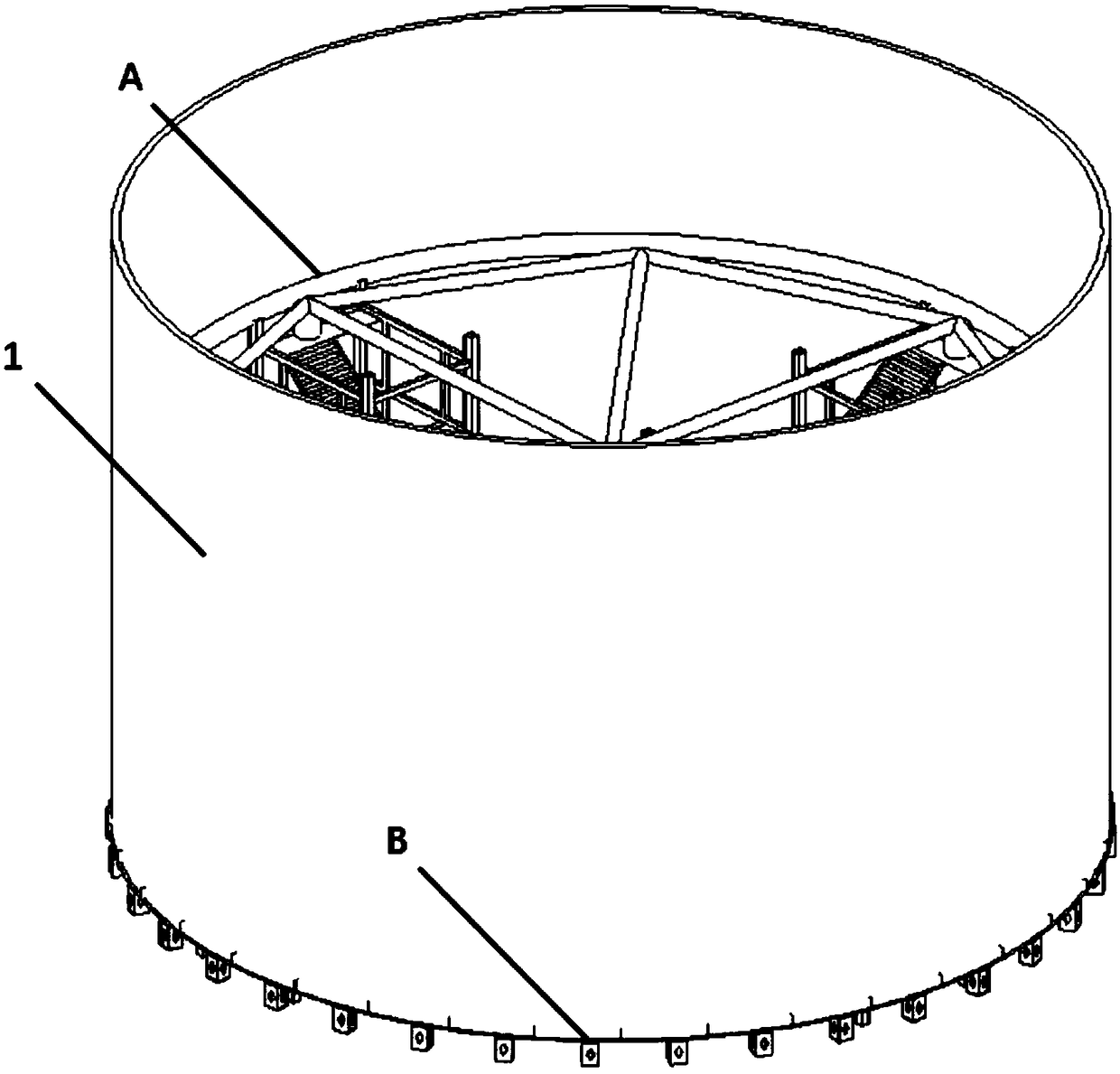

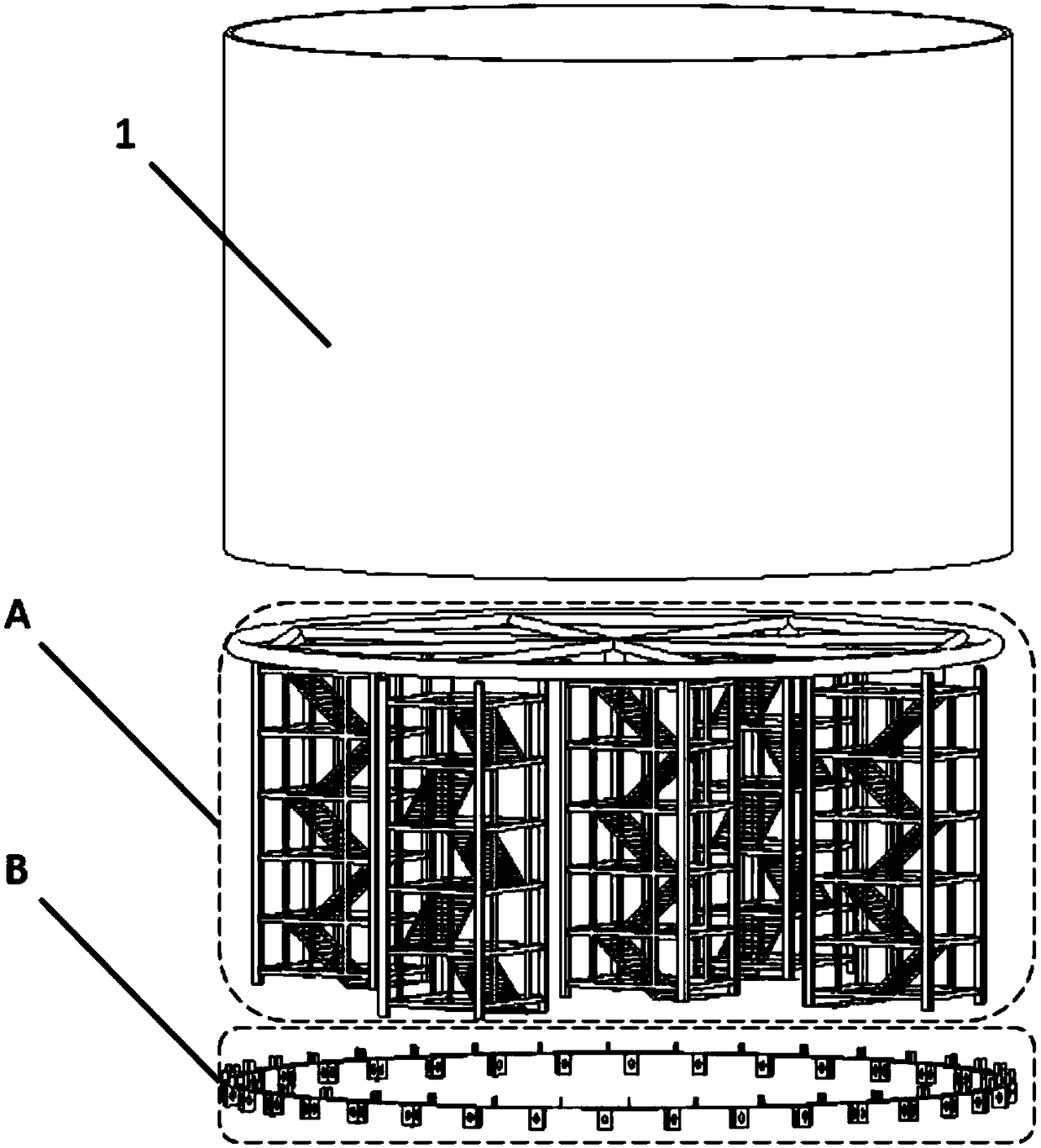

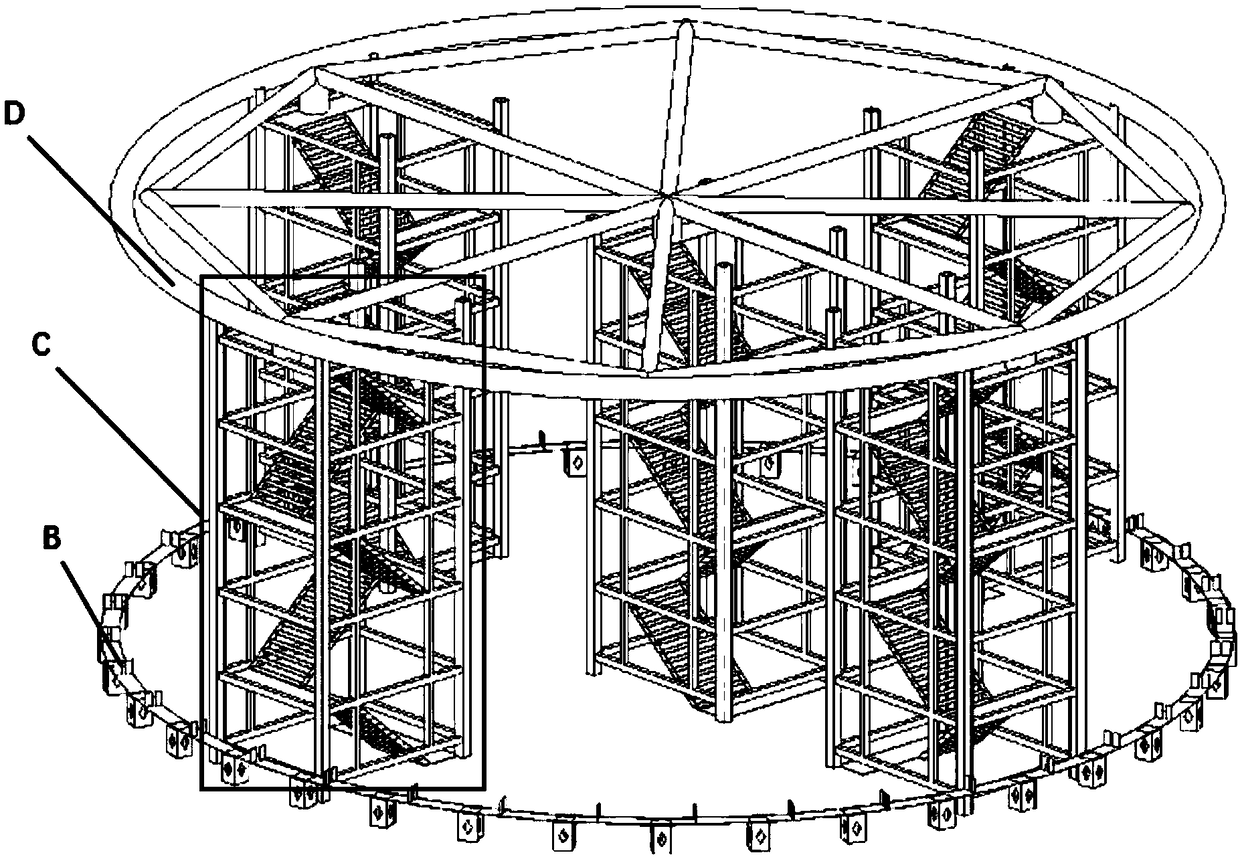

[0038] The use method of the integrated steel cylindrical bank revetment structure of the ladder column as shown in the figure includes the following steps:

[0039] (1) Prepare bottom limit assembly bracket B, ladder column integrated support frame C and top shaping frame D respectively;

[0040] The preparation method of the bottom limit assembly bracket B is as follows:

[0041] A plurality of buttresses 7 are evenly placed on the ground along the circumferential direction, and then a supporting plate 8 is welded on the plurality of buttresses 7, and then a plurality of limit brackets 9 are welded at equal intervals on the supporting plate 8. Each limit bracket 9 includes two limit plates arranged along the same radial direction of the pallet 8, and a gap for inserting the steel cylindrical bank protection structure 1 is left between the two limit plates. The r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com