Organic waste gas recovery system and organic waste gas recovery method

A technology of organic waste gas and recovery system, applied in separation methods, chemical instruments and methods, gas treatment, etc., can solve the problems of welding seam detachment, low cooling efficiency, economic loss of users, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

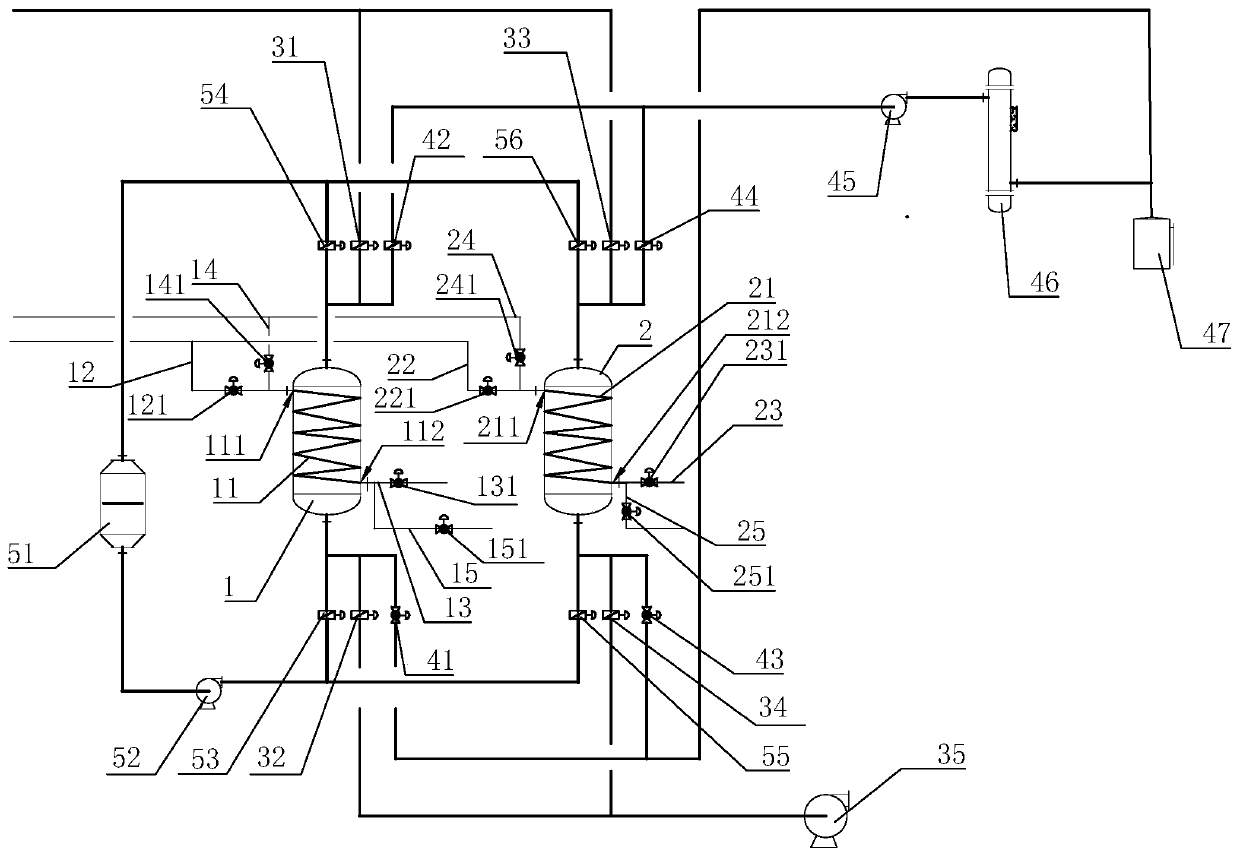

[0026] Embodiment 1: An organic waste gas recovery system, including an alternating adsorption and desorption module, the alternating adsorption and desorption module includes a first adsorption bed 1 and a second adsorption bed 2, and the first adsorption bed 1 is provided with a first steam inlet 111 and the first steam coil 11 of the first steam outlet 112, the second adsorption bed 2 is provided with the second steam coil 21 with the second steam inlet 211 and the second steam outlet 212, the first steam inlet 111 is provided with The first steam inlet pipe 12 of the first steam inlet control valve 121 communicates with the output port of the external steam input device (not shown), and the second steam inlet 211 passes through the second steam inlet pipe provided with the second steam inlet control valve 221 22 communicates with the output port of the external steam input device, the first steam outlet 112 communicates with the first exhaust pipe 13 provided with the first...

Embodiment 2

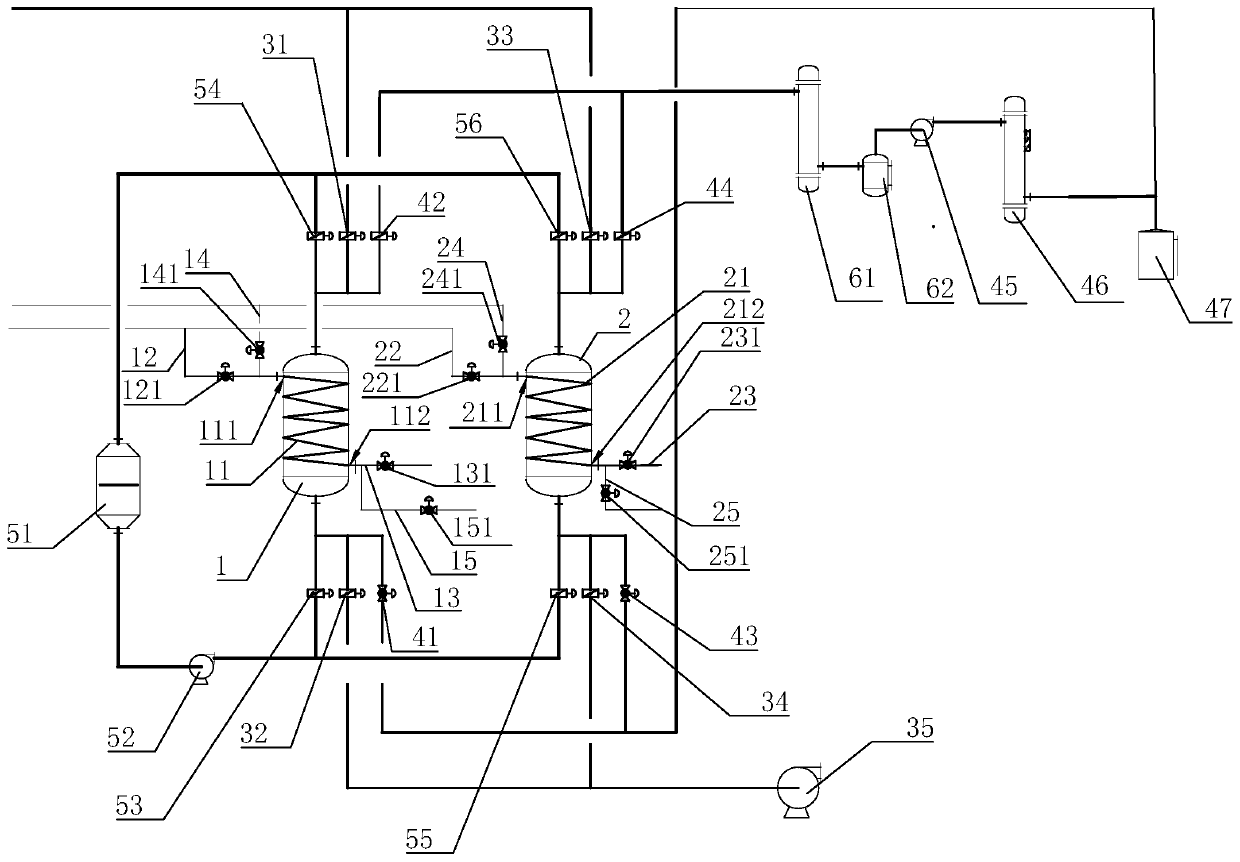

[0030] Embodiment 2: the rest is the same as Embodiment 1, the difference is that the desorption assembly also includes a second cooler 61 and a second storage tank 62, and the second storage tank 62 is provided with an input port at the side and an upper The output port of the second storage tank 62, the input port and the output port of the second storage tank 62 are respectively connected with the inside of the second storage tank 62, and the input port of the second cooler 61 is connected with the first desorption outlet control valve 42 and the first The input port of the adsorption bed 1 is connected, and the input port of the second cooler 61 is also communicated with the second desorption outlet control valve 44 and the input port of the second adsorption bed 2 through pipelines, and the output port of the second cooler 61 is connected through the pipeline. The pipeline communicates with the input port of the second storage tank 62 , and the output port of the second st...

Embodiment 3

[0031] Embodiment 3: The organic waste gas recovery method using the organic waste gas recovery system described in Embodiment 1 includes the following steps:

[0032] Set adsorption time, desorption temperature, continuous desorption time, first cooling temperature and second cooling temperature, and continuously transport organic waste gas through the external organic waste gas input port; where the set desorption temperature range is 100~120°C , the set continuous desorption time range is 1~2 hours, the set first cooling temperature range is 60~75°C, and the set second cooling temperature is 30~35°C

[0033] Synchronously open the first water inlet control valve 141, the first drainage control valve 151, the first adsorption inlet control valve 31 and the first adsorption outlet control valve 32 and close the first steam inlet control valve 121, the first exhaust steam control valve 131, The first desorption inlet control valve 41, the first desorption outlet control va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com