Continuous annealing method for hot stamping forming steel

A technology of hot stamping and annealing, which is applied in heat treatment furnaces, heat treatment equipment, heat treatment process control, etc., can solve the problems of low production efficiency of surface oxide film, affect the phase transition process of workpiece body, affect heat transfer and thermal conductivity, etc., and achieve Good applicability, improved bonding firmness, and good firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

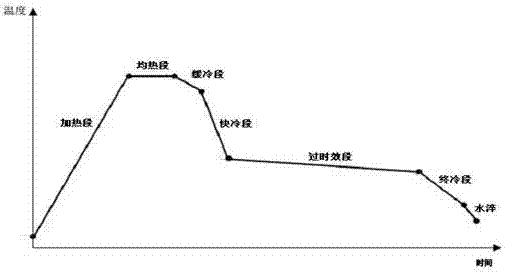

[0026] Embodiment 1: The specific process of the continuous annealing method of the hot stamping formed steel is as follows.

[0027] The mass fraction of the chemical composition of the hot stamping forming steel is: C 0.21%, Mn 1.40%, Si 0.30%, S0.006%, P 0.015%, Al 0.035%, Cr 0.20%, B 0.002%, and the rest are iron and unavoidable impurities.

[0028] The continuous annealing process is as follows: 1) Annealing process: the temperature of the uniform temperature section is 780°C, the start temperature of the rapid cooling is 680°C, the end temperature of the rapid cooling is 390°C, the aging end temperature is 360°C, the end temperature of the final cooling section is 150°C, and the temperature after water quenching is 43 ℃. The process speed is 100m / min. The dew point values are +14°C in the heating section, +15°C in the uniform temperature section, and +16°C in the slow cooling section.

[0029] 2) Smoothing process: the smoothing elongation rate is 1.2%, the rolling ...

Embodiment 2

[0031] Embodiment 2: The specific process of the continuous annealing method of the hot stamping formed steel is as follows.

[0032] The mass fraction of the chemical composition of the hot stamping forming steel is: C 0.22%, Mn 1.30%, Si 0.35%, S0.006%, P 0.020%, Al 0.030%, Cr 0.50%, B 0.005%, and the rest are iron and unavoidable impurities.

[0033] The continuous annealing process is as follows: 1) Annealing process: the temperature of the uniform temperature section is 790°C, the start temperature of the rapid cooling is 670°C, the end temperature of the rapid cooling is 400°C, the aging end temperature is 370°C, the end temperature of the final cooling section is 160°C, and the temperature after water quenching is 45°C. ℃. The process speed is 95m / min. The dew point values are +19°C in the heating section, +19°C in the uniform temperature section, and +20°C in the slow cooling section.

[0034] 2) Smoothing process: the smoothing elongation rate is 1.5%, the rollin...

Embodiment 3

[0036] Embodiment 3: The specific process of the continuous annealing method of the hot stamping formed steel is as follows.

[0037] The mass fraction of the chemical composition of the hot stamping forming steel is: C 0.25%, Mn 1.40%, Si 0.18%, S0.005%, P 0.022%, Al 0.050%, Cr 0.30%, B 0.003%, and the rest are iron and unavoidable impurities.

[0038]The continuous annealing process is as follows: 1) Annealing process: the temperature of the uniform temperature section is 800°C, the start temperature of the rapid cooling is 690°C, the end temperature of the rapid cooling is 410°C, the aging end temperature is 380°C, the end temperature of the final cooling section is 150°C, and the temperature after water quenching is 50°C ℃. The process speed is 80m / min. The dew point values are +12°C in the heating section, +13°C in the uniform temperature section, and +15°C in the slow cooling section.

[0039] 2) Smoothing process: the smoothing elongation rate is 2.0%, the rolling ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com