Photolithographic alignment method for manufacturing a semiconductor device

A photolithographic alignment and semiconductor technology, which is applied in the direction of semiconductor devices, semiconductor/solid-state device parts, electric solid-state devices, etc., can solve problems such as difficult identification, unclear marks, and complex structures, and achieve improved recognition rates, Meet the requirements, the effect of simple implementation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0074] as attached Figure 7 To attach Figure 11 As shown, a specific embodiment of a photolithography alignment method for manufacturing a semiconductor device. When the marking area is located in the exposure area, and the marking substance 5 is a liquid substance, the photolithography alignment method includes the following steps:

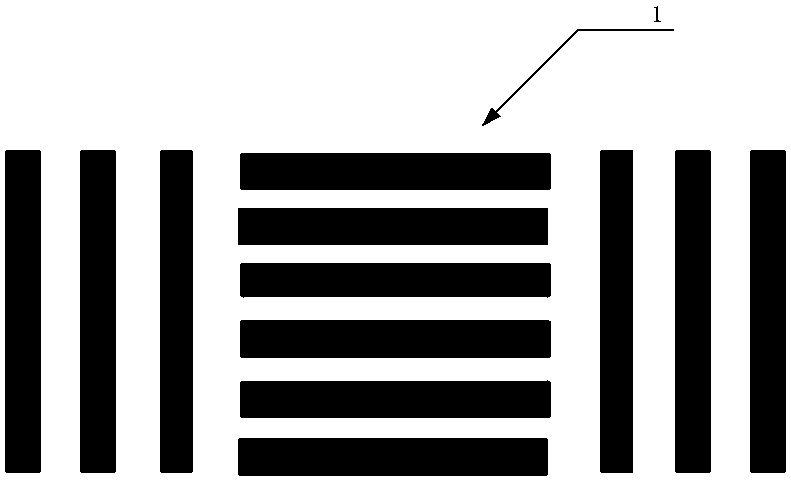

[0075] S1001: After forming an oxide layer on the upper part of the base layer 2, form a photolithographic alignment mark 1 by thin film photolithography or etching, as shown in the attached figure 2 shown;

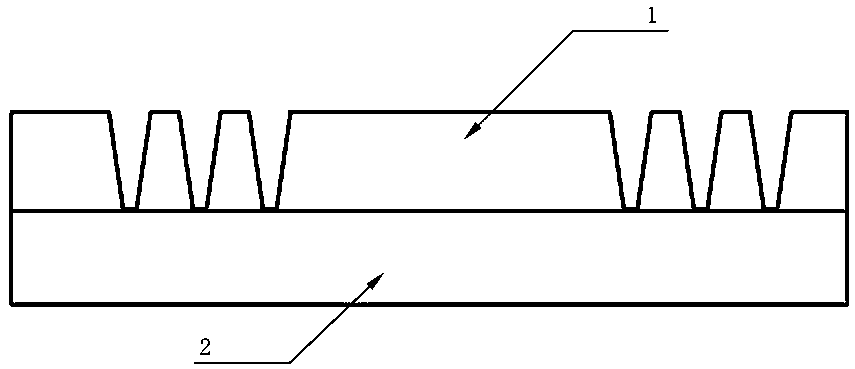

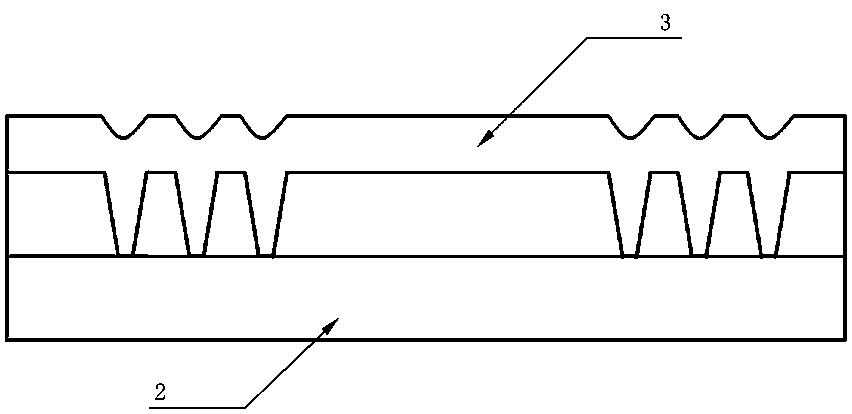

[0076] S1002: grow a metal layer (process alignment layer 3) through the thin film, as attached image 3 shown;

[0077] S101: dripping or depositing a marking substance 5 in the marking area of the process alignment layer 3, as attached Figure 7 As shown; the marking substance 5 uses a negative photoresist to add pigments, so that there is a contrast between the marking substance 5 and the process alignment layer 3, and the exposu...

Embodiment 2

[0085] When the marking area is located in the non-exposed area, and the marking substance 5 is a liquid substance, the photolithographic alignment method includes the following steps:

[0086] S1001: After forming an oxide layer on the upper part of the base layer 2, form a photolithographic alignment mark 1 by thin film photolithography or etching, as shown in the attached figure 2 shown;

[0087] S1002: grow a metal layer (process alignment layer 3) through the thin film, as attached image 3 shown;

[0088] S101: dripping or depositing a marking substance 5 in the marking area of the process alignment layer 3, as attached Figure 7 As shown; the marking substance 5 uses a negative photoresist to add pigments, so that there is a contrast between the marking substance 5 and the process alignment layer 3, and the exposure wavelength of the negative photoresist is different from the exposure wavelength of the positive photoresist;

[0089] S102: remove part of the markin...

Embodiment 3

[0096] When the marking area is located in the exposure area, and the marking substance 5 is a solid substance, the photolithographic alignment method includes the following steps:

[0097] S1001: After forming an oxide layer on the upper part of the base layer 2, form a photolithographic alignment mark 1 by thin film photolithography or etching, as shown in the attached figure 2 shown;

[0098] S1002: grow a metal layer (process alignment layer 3) through the thin film, as attached image 3 shown;

[0099] S101: dripping or depositing a marking substance 5 in the marking area of the process alignment layer 3, as attached Figure 7 Shown; Marking substance 5 adopts POLY (polysilicon) or SIPOS (semi-insulating polysilicon);

[0100] S102: remove part of the marking substance 5, so that only the concave area of the marking area has the marking substance 5, so as to form the secondary alignment mark 4, as attached Figure 8 shown;

[0101] S103: On the basis of the fore...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com