A continuous rectification separation method and equipment for a propylene carbonate crude product

A technology for propylene carbonate and rectification separation, which is applied in separation methods, distillation separation, chemical instruments and methods, etc., can solve the problems of difficulty in meeting battery-level purity requirements and high operating costs, and achieves improved mass transfer and separation efficiency. Liquid contact space, the effect of improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

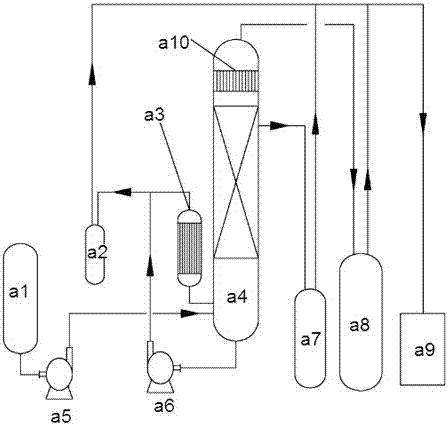

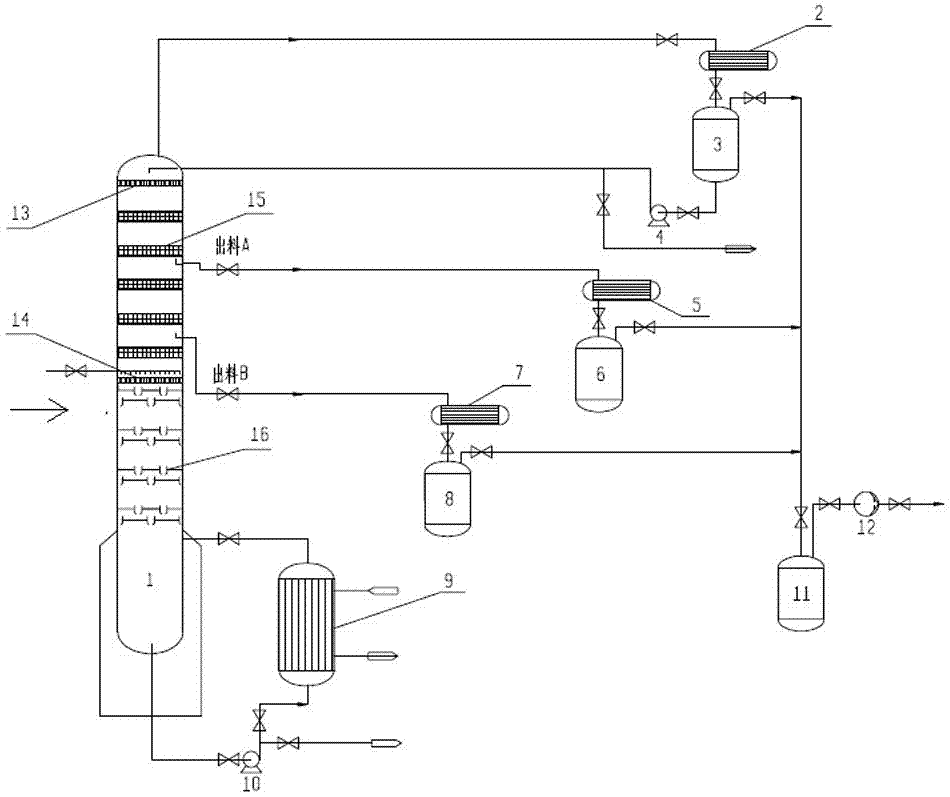

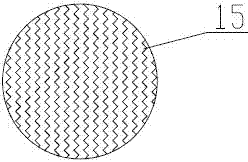

[0034] Embodiment 1: with reference to attached figure 2 , the continuous rectification separation method of a kind of propylene carbonate crude product that the present invention mentions, its technical scheme is to comprise the following steps:

[0035] Step 1: The operating temperature is 90-130°C, and the crude propylene carbonate product with a product purity of 98% enters the middle part of the propylene carbonate rectification tower 1, and the inner cavity of the propylene carbonate rectification tower 1 is provided with a reflux distributor from top to bottom 13. Multiple groups of diamond-shaped reaction promotion units 15, feed distributor 14 and multiple groups of liquid stripping filter discs 16, the outside of the propylene carbonate rectifying tower 1 are respectively connected to the rectifying tower top condenser 2 and the A discharge line condenser 5. B discharge line condenser 7 and rectification column kettle reboiler 9;

[0036] Step 2: After sufficient g...

Embodiment 2

[0046] Embodiment 2: the continuous rectification separation method of a kind of propylene carbonate crude product that the present invention mentions, its technical scheme is to comprise the following steps:

[0047] Step 1: the operating temperature is 90°C, and the propylene carbonate crude product with a product purity of 98% enters the middle part of the propylene carbonate rectification tower 1, and the inner cavity of the propylene carbonate rectification tower 1 is provided with a reflux distributor 13, Multiple groups of diamond-shaped reaction promotion units 15, feed distributors 14 and multiple groups of liquid stripping filter discs 16, the outside of the propylene carbonate rectifying tower 1 are respectively connected to the rectifying tower top condenser 2, the A discharge line condenser 5, B discharge line condenser 7 and rectifying column kettle reboiler 9;

[0048] Step 2: After sufficient gas-liquid exchange in the diamond-shaped reaction promotion unit 15 ...

Embodiment 3

[0052] Embodiment 3: the continuous rectification separation method of a kind of propylene carbonate crude product that the present invention mentions, its technical scheme is to comprise the following steps:

[0053] Step 1: the operating temperature is 130°C, and the propylene carbonate crude product with a product purity of 98% enters the middle part of the propylene carbonate rectification tower 1, and the inner cavity of the propylene carbonate rectification tower 1 is provided with a reflux distributor 13, Multiple groups of diamond-shaped reaction promotion units 15, feed distributors 14 and multiple groups of liquid stripping filter discs 16, the outside of the propylene carbonate rectifying tower 1 are respectively connected to the rectifying tower top condenser 2, the A discharge line condenser 5, B discharge line condenser 7 and rectifying column kettle reboiler 9;

[0054] Step 2: After sufficient gas-liquid exchange in the diamond-shaped reaction promotion unit 15...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com