Preparation method and application of material for mineralization of purified water after reverse osmosis

A pure water and reverse osmosis technology, applied in the field of water treatment, can solve the corrosion problems of metal equipment, achieve high conversion rate, reduce equipment, and avoid equipment loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

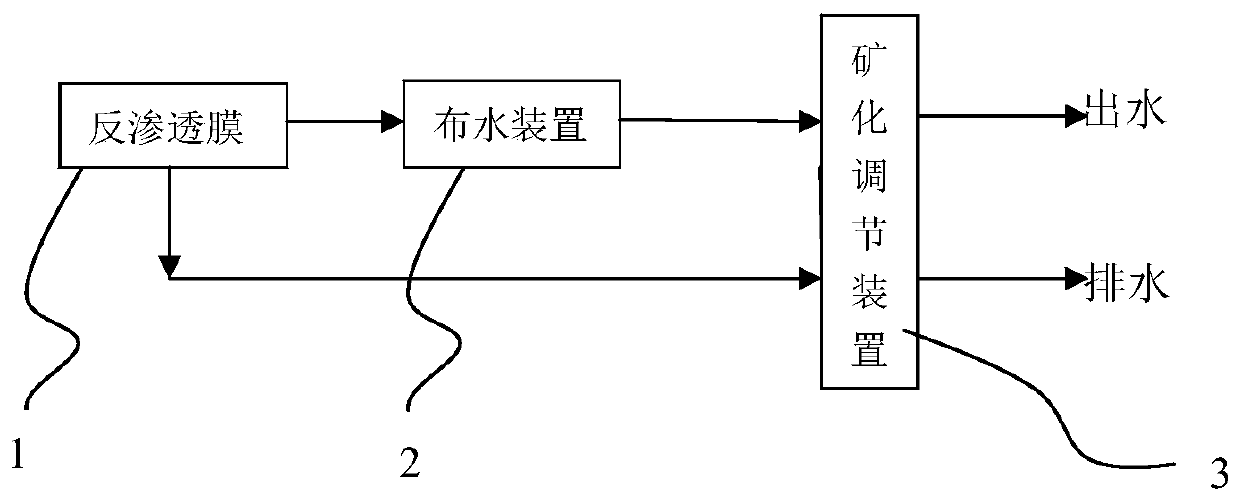

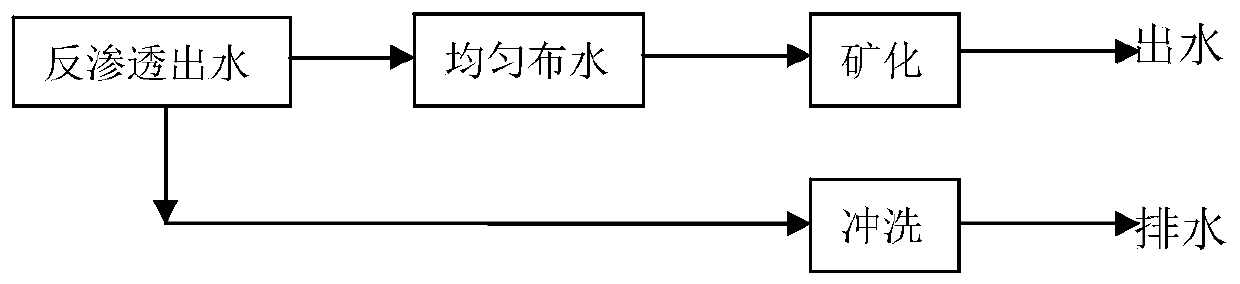

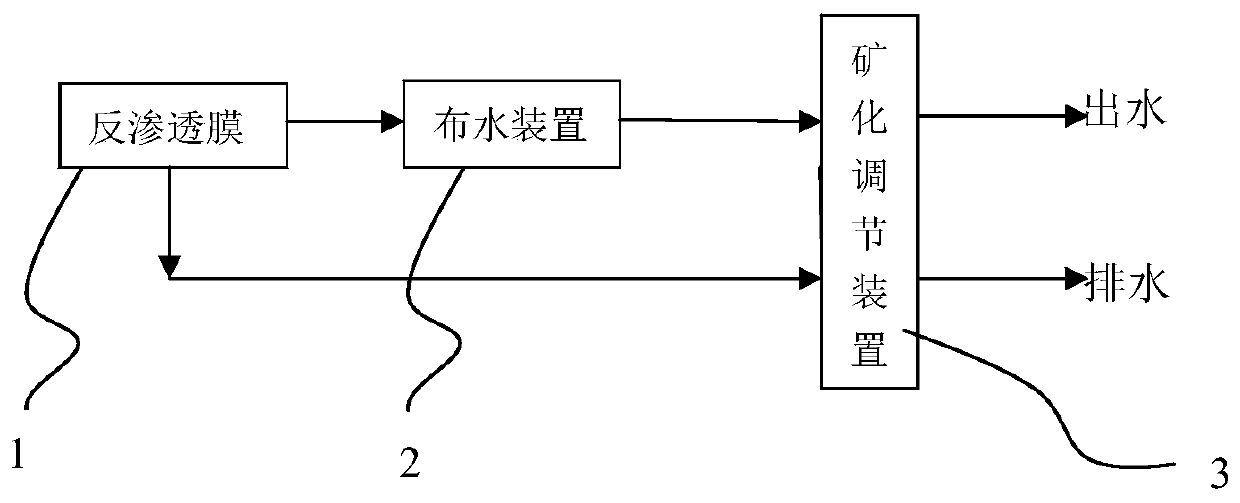

Image

Examples

preparation example Construction

[0027] What the present invention relates to is the preparation method for the mineralization material of purified water after reverse osmosis, comprises the following steps:

[0028] a. Wash the shells and dry them in the air; put them into a muffle furnace for calcination, take them out to cool, and crush them to obtain coarse shell powder. The main component of the shell is calcium carbonate. Calcining the shell through the high temperature of the muffle furnace makes the calcium carbonate react to produce calcium oxide and carbon dioxide, and makes the structure of the shell very loose, which is conducive to the next step of dissolution.

[0029] b. Pulverizing the periclase to obtain periclase coarse powder. Periclase is a magnesium oxide mineral, mainly produced in marble, and is formed by metamorphism of dolomite at high temperature. Crush the periclase for the next step of dissolution.

[0030] c. Put the coarse shell powder and the periclase coarse powder in the con...

Embodiment 1

[0046] The preparation method of the mineralized material used for pure water after reverse osmosis comprises the following steps:

[0047]a. Wash the shells and dry them in the air; put them into a muffle furnace for calcination, take them out to cool, and crush them to obtain coarse powder of shells; crush the shells to a particle size of 80 mesh.

[0048] b. Grinding the periclase to obtain periclase coarse powder; pulverizing the periclase to a particle size of 80 mesh.

[0049] c. Put the coarse shell powder and the periclase coarse powder in the container, add water several times, and grind them into a paste.

[0050] d. Add lactic acid to the above pasty suspension several times, stir evenly in an 80°C water bath, and pour out the suspension; the concentration of the lactic acid solution is 70%.

[0051] e. Collect the suspension that has been poured out many times, heat to evaporate the water, and when the suspension turns into a paste, cool to precipitate crystals to...

Embodiment 2

[0055] The preparation method of the mineralized material used for pure water after reverse osmosis comprises the following steps:

[0056] a. Wash the shells and dry them in the air; put them into a muffle furnace for calcination, take them out to cool, and crush them to obtain coarse shell powder; crush the shells to a particle size of 100 mesh.

[0057] b. Grinding the periclase to obtain periclase coarse powder; pulverizing the periclase to a particle size of 100 mesh.

[0058] c. Put the coarse shell powder and the periclase coarse powder in the container, add water several times, and grind them into a paste.

[0059] d. Add lactic acid to the above pasty suspension several times, stir evenly in a 90°C water bath, and pour out the suspension; the concentration of the lactic acid solution is 80%.

[0060] e. Collect the suspension that has been poured out many times, heat to evaporate the water, and when the suspension turns into a paste, cool to precipitate crystals to o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com