Heat Dissipation Structure and Packaging Technology of igbt Module in Power Converter

A technology of heat dissipation structure and packaging technology, which is applied in the manufacture of semiconductor devices, electric solid devices, semiconductor/solid devices, etc., can solve the problems of working life and reliability affecting the normal operation of devices or systems, and achieve excellent in-plane thermal conductivity, Effect of enhancing reliability and satisfying heat dissipation requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with drawings and embodiments.

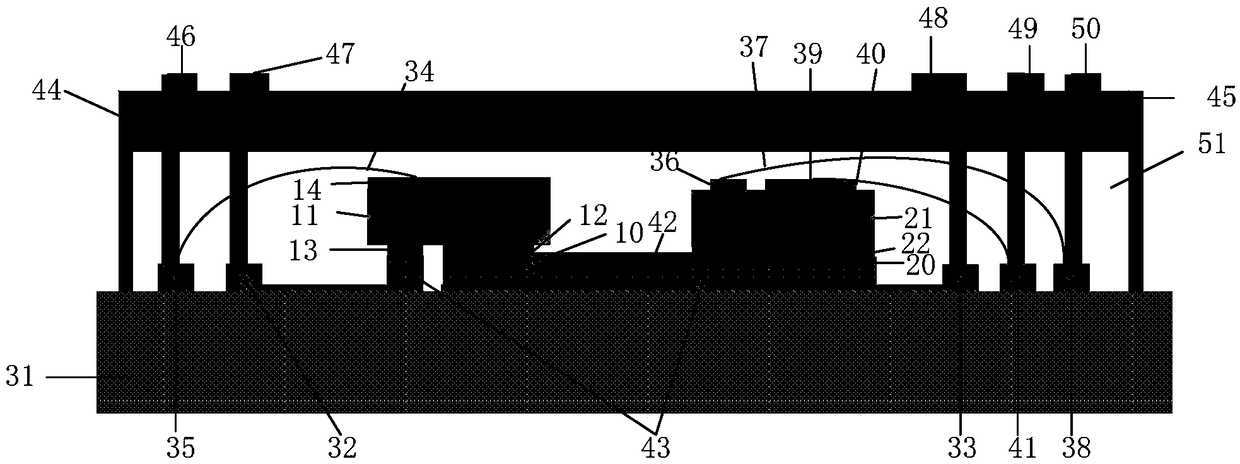

[0035] The invention proposes a heat dissipation structure of an IGBT module in a power converter, including a substrate, a chip, a heat sink, a graphene heat dissipation layer, a graphene-based interconnection material, a busbar and silica gel.

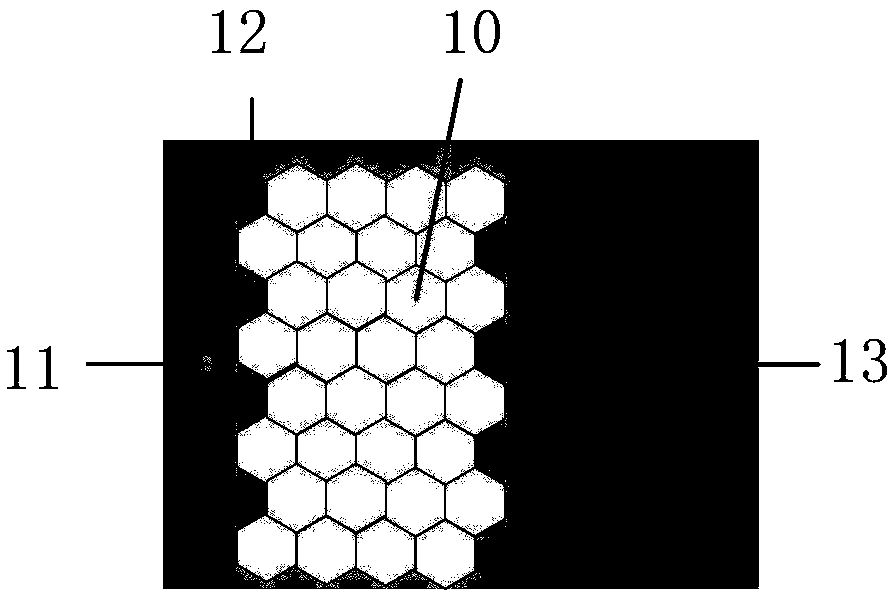

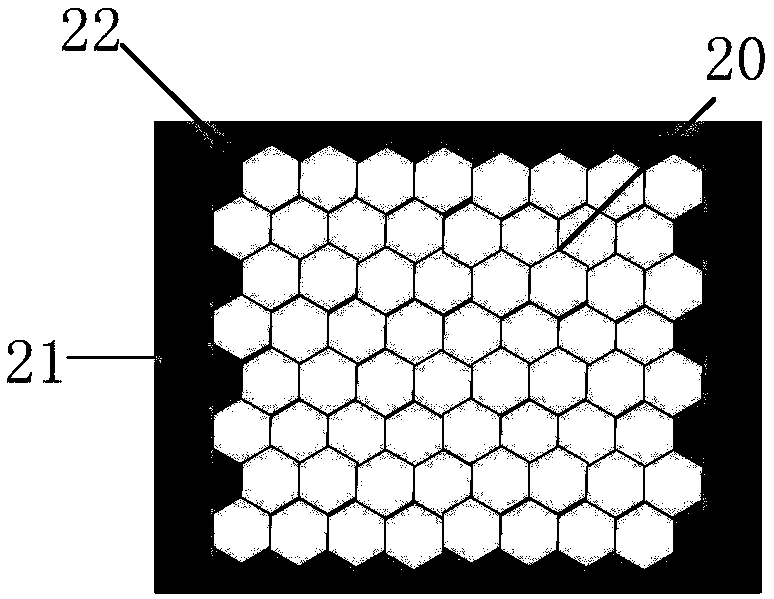

[0036] Wherein the monolayer graphene film prepared by chemical vapor deposition is used as the heat dissipation layer for the surface of the emitter 12 of the first IGBT chip and the surface of the collector 22 of the second IGBT chip, see figure 1 and figure 2 . figure 1 The first IGBT chip 11 has an emitter 12 and a gate 13 on the upper surface of the first IGBT chip, and the upper surface of the first IGBT chip emitter 12 is a first single-layer graphene film 10 . figure 2 There is a collector electrode 22 of the second IGBT chip on the upper surface of the second IGBT chip 21 , and the second single-layer graphene fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com