Shell protective structure of electro-hydraulic servo valve

An electro-hydraulic servo valve and protective structure technology, applied in the field of electro-hydraulic servo, can solve the problems of servo valve performance and quality influence, servo valve torque motor short circuit, coil and enameled wire corrosion, etc., to improve the protection level, high reliability, The effect of stable and effective work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

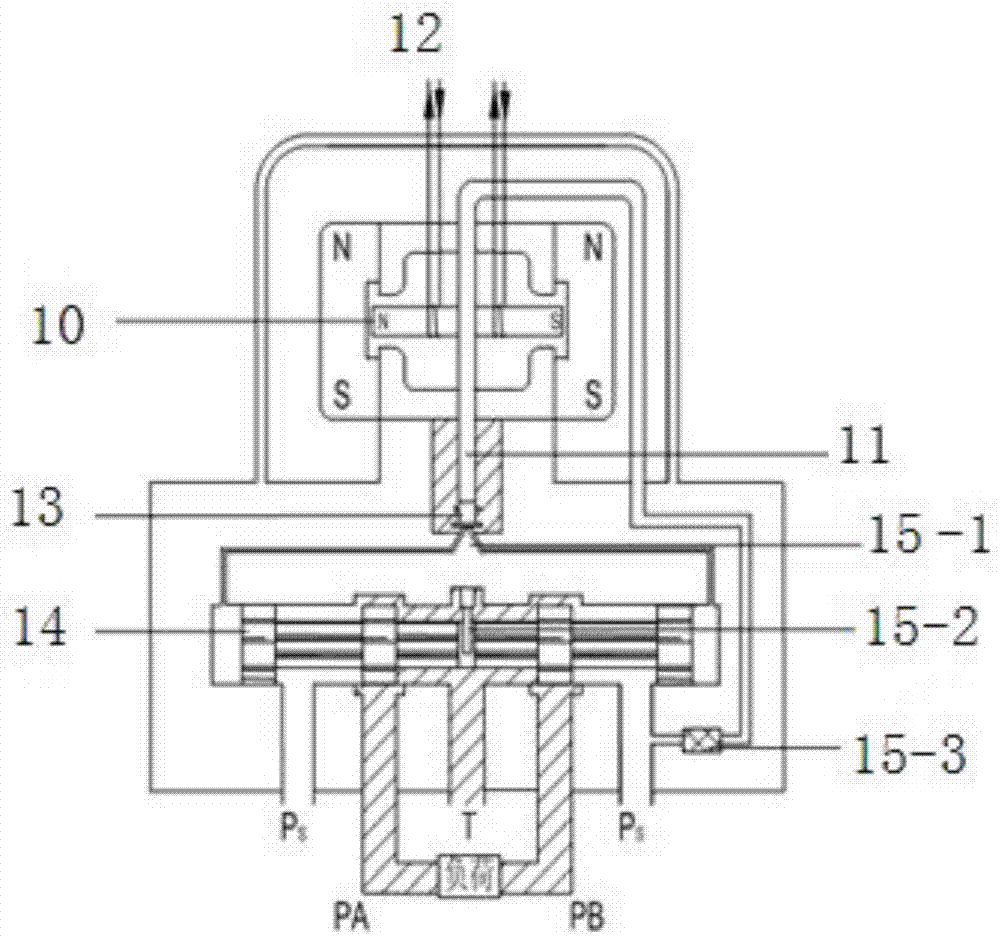

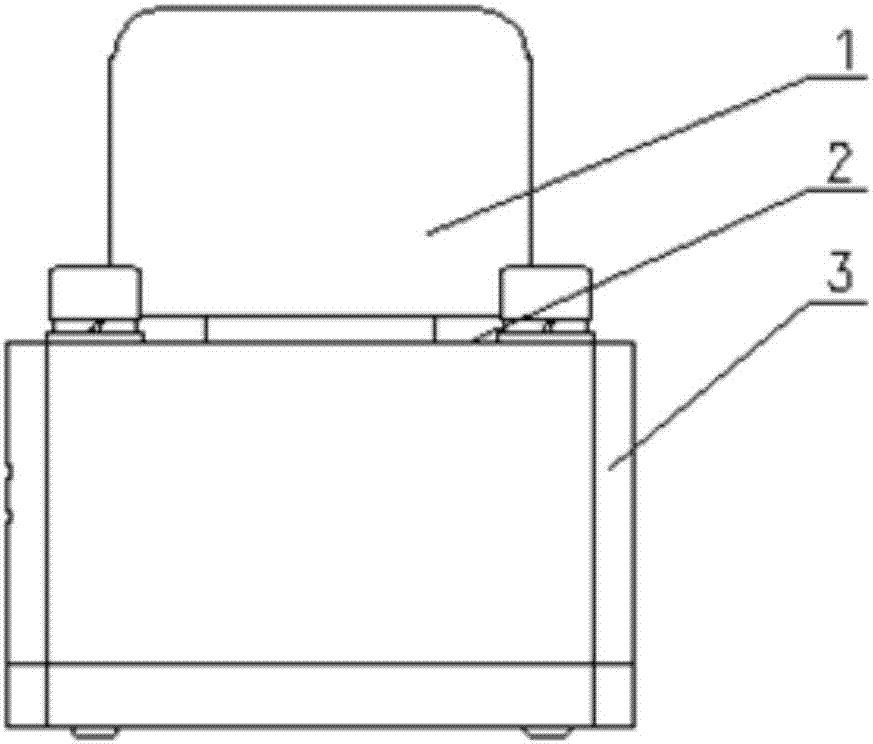

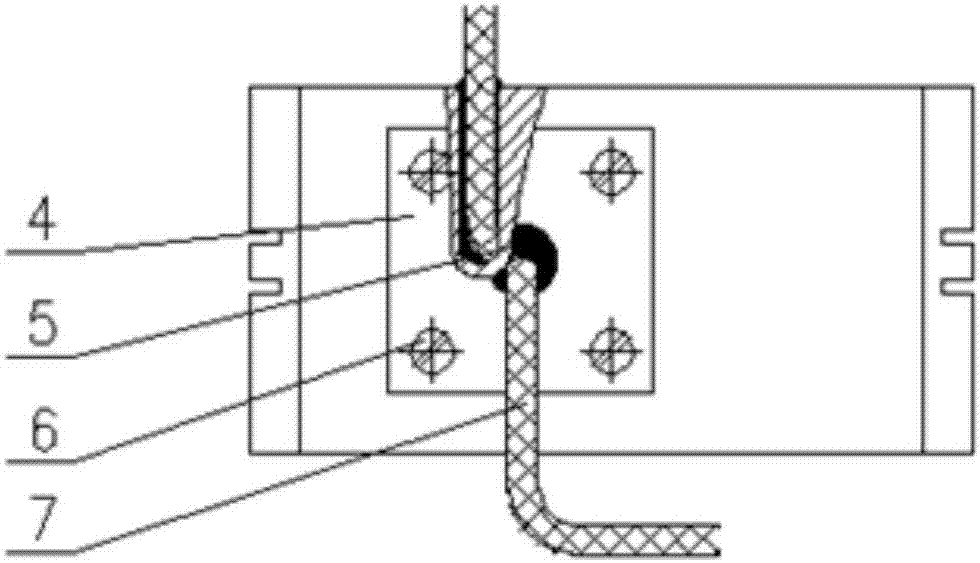

[0020] Such as Figure 2 to Figure 4 As shown, a shell protection structure of an electro-hydraulic servo valve includes an upper cover 1, S-7 polysulfide rubber 2, a valve body 3, a cover plate 4, polyurethane sealant 5, screws 6, shielding wire 7, and sealant 8 . The shielding wire 7 enters through the threading hole on the side of the valve body 3 and passes upward through the outlet hole on the upper surface of the valve body 3, and is welded and connected with the lead wire of the motor coil. The threading hole is filled with polyurethane sealant 5, and the cover plate 4 is fixedly connected with fasteners; After high-temperature aging treatment, the protective structure of the entire electro-hydraulic servo valve shell is formed.

[0021] The processing method of the improved structure of the present invention is as follows:

[0022] Pass the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com