A kind of processing device and processing method of vanadium-titanium magnetite

A vanadium titanomagnetite and processing method technology, applied in the field of metallurgy, can solve the problems of long process flow, low product quality, poor economy and the like, and achieve the effects of simple equipment operation, good reduction effect and low operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

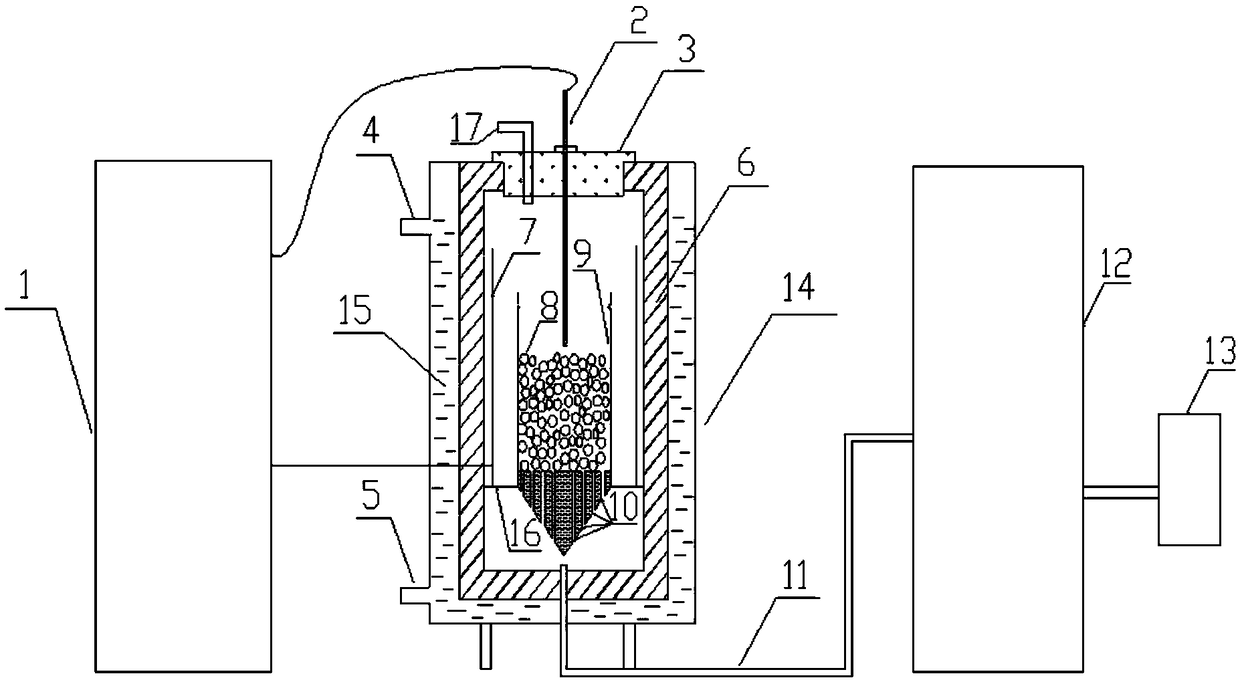

[0065] use figure 1 The shown processing device processes the vanadium-titanium magnetite concentrate. The main components and mass percentages of the vanadium-titanium magnetite concentrate are shown in Table 1, and Table 1 shows the main components and contents of the vanadium-titanium magnetite concentrate.

[0066] Table 1 Main components and content / % of vanadium-titanium magnetite concentrate

[0067] sample name

TF

Fe 2 o 3

FeO

TiO 2

S

P

Vanadium Titanium Magnetite Concentrate

52.60

41.61

30.23

12.91

0.65

0.008

[0068] Note: TFe is the total mass percentage of iron elements in vanadium-titanium magnetite concentrate.

[0069] making carbon pellets

[0070] Mix vanadium-titanium magnetite concentrate with anthracite coal powder (reducing agent) and bentonite (binder) according to the ratio of 100:28:3, mix them and briquette to obtain The cylindrical carbon-containing green pellets were dried at 110°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com