Safe and environment-friendly type natural stone waterproof alkali-resistant backing adhesive and preparation method thereof

A safe, environmentally friendly and natural technology, applied in the direction of adhesives, adhesive additives, non-polymer adhesive additives, etc., can solve the problems of white flowers, high cost, insufficient bonding strength, etc., and achieve simple preparation methods and mild process conditions , Improve the effect of application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

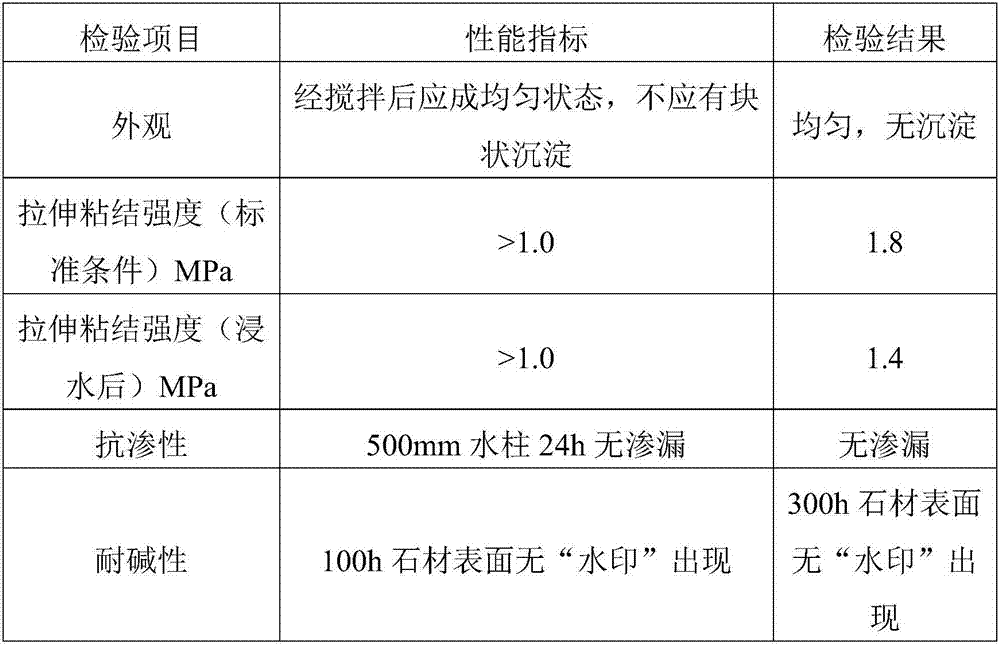

Examples

Embodiment 1

[0025] A safe and environment-friendly natural stone waterproof and alkali-resistant adhesive, the adhesive includes the following components and contents by weight: 5 parts of liquid mixture, 5 parts of powder mixture, wherein the liquid mixture includes the following components and contents by weight: acrylic acid 400 parts of emulsion, 100 parts of lithium silicate aqueous solution, 2 parts of bactericide, 2 parts of defoamer and 496 parts of water, the powder mixture includes the following components and parts by weight: 450 parts of kaolin, 300 parts of heavy calcium carbonate powder, 250 parts of snow white powder, 2 parts of superplasticizer and 2 parts of cellulose.

[0026] Wherein, the acrylic emulsion is commercially available Bardford RS-2608; in the lithium silicate aqueous solution, the mass percentage of lithium silicate is 35%, and the modulus of lithium silicate is 6; the fungicide is commercially available KATHON LXE; The foaming agent is commercially availab...

Embodiment 2

[0033] A safe and environment-friendly natural stone waterproof and alkali-resistant adhesive, the adhesive includes the following components and contents by weight: 6 parts of liquid mixture, 4 parts of powder mixture, wherein the liquid mixture includes the following components and contents by weight: acrylic acid 420 parts of emulsion, 95 parts of lithium silicate aqueous solution, 3 parts of bactericide, 1 part of defoamer and 550 parts of water, the powder mixture includes the following components and content by weight: 430 parts of kaolin, 320 parts of heavy calcium carbonate powder, 230 parts of snow white powder, 3 parts of superplasticizer and 1 part of cellulose.

[0034] Among them, the acrylic acid emulsion is commercially available Bardford RS-2608; in the lithium silicate aqueous solution, the mass percentage of lithium silicate is 45%, and the modulus of lithium silicate is 8; the bactericide is commercially available KATHON LXE; The foaming agent is commerciall...

Embodiment 3

[0039] A safe and environment-friendly natural stone waterproof and alkali-resistant adhesive, the adhesive includes the following components and parts by weight: 4 parts of liquid mixture, 6 parts of powder mixture, wherein the liquid mixture includes the following components and content by weight: acrylic acid 380 parts of emulsion, 105 parts of lithium silicate aqueous solution, 1 part of bactericide, 3 parts of defoamer and 450 parts of water, the powder mixture includes the following components and parts by weight: 480 parts of kaolin, 280 parts of heavy calcium carbonate powder, 270 parts of snow white powder, 1 part of superplasticizer and 3 parts of cellulose.

[0040]Among them, the acrylic acid emulsion is commercially available Bardford RS-2608; in the lithium silicate aqueous solution, the mass percentage of lithium silicate is 40%, and the modulus of lithium silicate is 4; the bactericide is commercially available KATHON LXE; The foaming agent is commercially avai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com