Water purifying agent and preparation method thereof

A water purifier and cement technology, which is applied in chemical instruments and methods, water/sewage treatment, adsorbed water/sewage treatment, etc., can solve the problems of chemical water purifiers will dissolve and the water purification effect is poor, and achieve the ability to purify water. Comprehensive, outstanding effect, strong adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

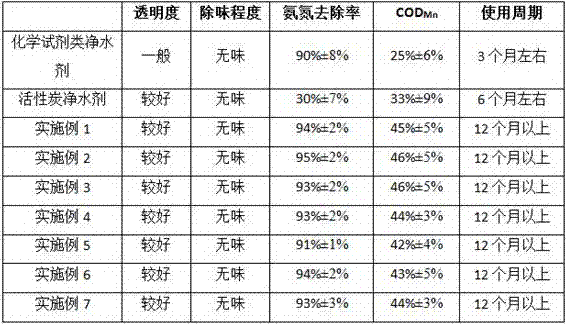

Image

Examples

Embodiment 1

[0018] Embodiment 1, a preparation method of a water purifying agent, is made from Codonopsis dregs, activated carbon, diatomite, bentonite, sodium silicate, aluminum sulfate, white Portland cement and gypsum, and the specific steps are: Step 1, Preparation of materials: Grinding Codonopsis dregs into 100-200 mesh particles, activated carbon into 6-100 mesh particles, diatomite, bentonite, sodium silicate, aluminum sulfate, white Portland cement and gypsum in powder form;

[0019] Step 2. Mixing: Weigh 30 parts of Codonopsis dregs, 15 parts of activated carbon, 15 parts of diatomite, 5 parts of bentonite, 5 parts of sodium silicate, 15 parts of aluminum sulfate, 5 parts of white Portland cement and 3 parts of gypsum After mixing, add 15 parts of water and stir again to obtain the mixture;

[0020] Step 3. Granulation: Put the mixture in a granule extruder to form granules to make granules with a particle size of 30-50 mm. After drying the granules naturally for 72 hours, place...

Embodiment 2

[0021] Embodiment 2, a preparation method of a water purifying agent, is made from Codonopsis dregs, activated carbon, diatomite, bentonite, sodium silicate, aluminum sulfate, white Portland cement and gypsum. The specific steps are: Step 1, Preparation of materials: Grinding Codonopsis dregs into 100-200 mesh particles, activated carbon into 6-100 mesh particles, diatomite, bentonite, sodium silicate, aluminum sulfate, white Portland cement and gypsum in powder form;

[0022] Step 2. Mixing: Weigh 50 parts of Codonopsis dregs, 30 parts of activated carbon, 20 parts of diatomite, 10 parts of bentonite, 10 parts of sodium silicate, 20 parts of aluminum sulfate, 10 parts of white Portland cement and 5 parts of gypsum After mixing, add 30 parts of water and stir again to obtain the mixture;

[0023] Step 3. Granulation: Put the mixture in a granule extruder to form granules to make granules with a particle size of 30-50 mm. After drying the granules naturally for 72 hours, place ...

Embodiment 3

[0024] Embodiment 3, a preparation method of a water purifying agent, is made from Codonopsis dregs, activated carbon, diatomite, bentonite, sodium silicate, aluminum sulfate, white Portland cement and gypsum, and the specific steps are: Step 1, Preparation of materials: Grinding Codonopsis dregs into 100-200 mesh particles, activated carbon into 6-100 mesh particles, diatomite, bentonite, sodium silicate, aluminum sulfate, white Portland cement and gypsum in powder form;

[0025] Step 2, mixing: Weigh 42 parts of Codonopsis dregs, 25 parts of activated carbon, 18 parts of diatomite, 8 parts of bentonite, 8 parts of sodium silicate, 18 parts of aluminum sulfate, 10 parts of white Portland cement and 5 parts of gypsum After mixing, add 25 parts of water and stir again to obtain the mixture;

[0026] Step 3. Granulation: Put the mixture in a granule extruder to form granules to make granules with a particle size of 30-50 mm. After drying the granules naturally for 72 hours, plac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com