Preparation method of 42CrMo steel casting rolling forming ring member sample for EBSD testing

A forming ring and steel casting technology, applied in the preparation of test samples, measuring devices, material analysis using wave/particle radiation, etc., can solve the problems of low pattern recognition rate, long preparation cycle, high flatness and smoothness, etc. Achieve the effect of high pattern recognition rate, convenient preparation and convenient material collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

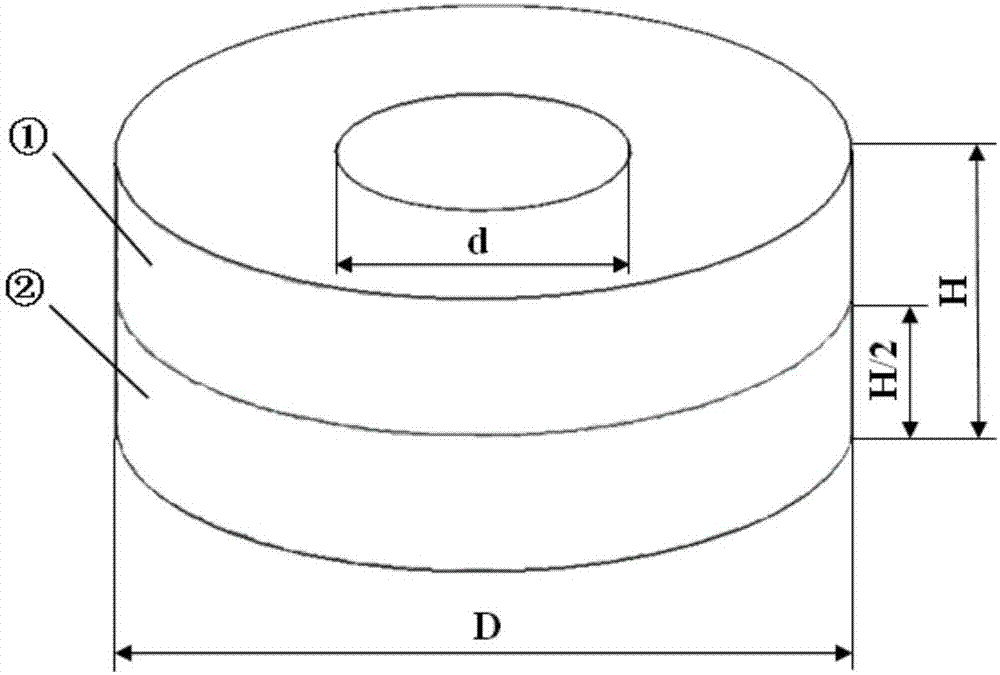

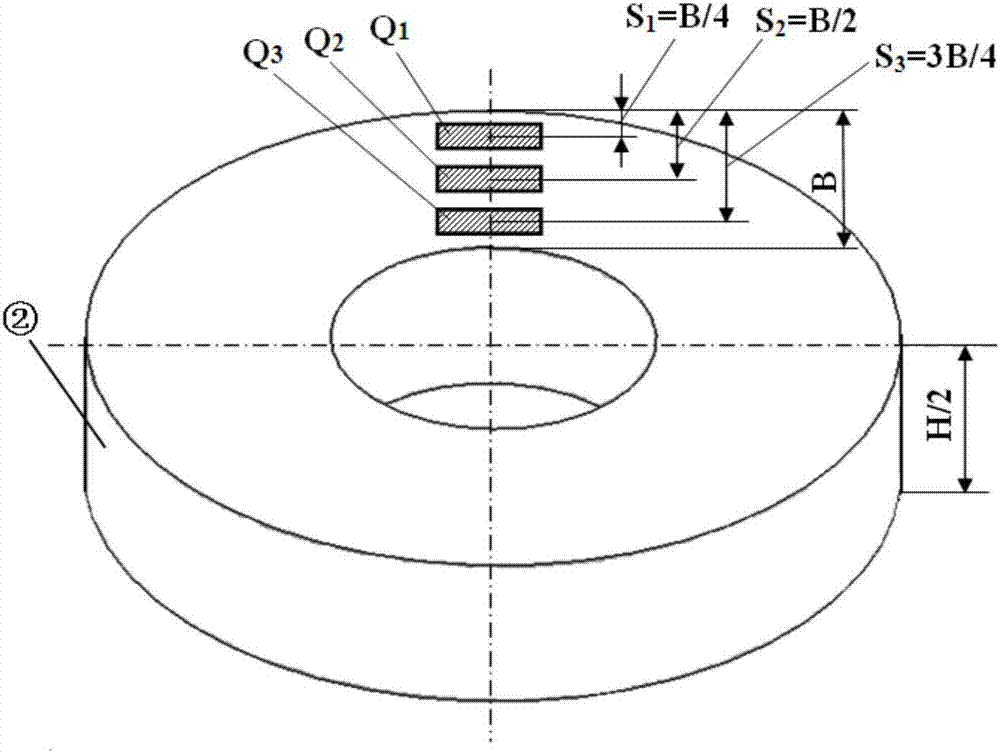

[0024] Such as figure 1 As shown, take the outer diameter of the ring D =320mm, inner diameter of ring d =260mm, ring wall thickness B =30mm, ring height H =50mm, the process steps are as follows:

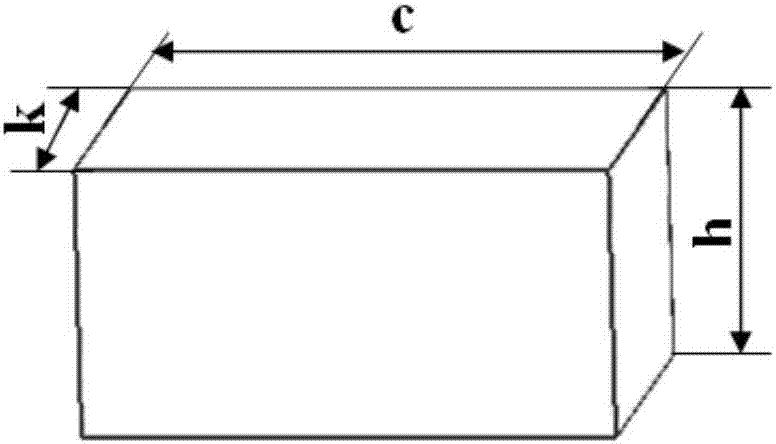

[0025] (1) Cut the unit body Q of the specimen: if figure 1 , 2 As shown, the specimen unit body Q is cut at different positions along the radial wall thickness direction in the middle section of the 42CrMo steel cast rolling forming ring in the height direction by using a CNC slow-moving wire cutting machine. 1 , Q 2 , Q 3 , the shape of the specimen unit body is as follows image 3 For the cuboid shown, the length of the cuboid is c=5mm, the width k=4mm, the height h=2mm, and the unit body Q of the specimen is 1 , Q 2 , Q 3 The distances from the center of the ring to the outer surface of the ring are S 1 =7.5mm, S 2 =15mm,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com