Lead concentrate processing technology

A treatment process and lead concentrate technology, applied in the field of lead concentrate treatment process, can solve the problems of ineffective separation of smoke and dust, difficulty in recycling and reuse of smoke and dust, and achieve the effects of saving equipment investment, strong adaptability, and shortening the process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

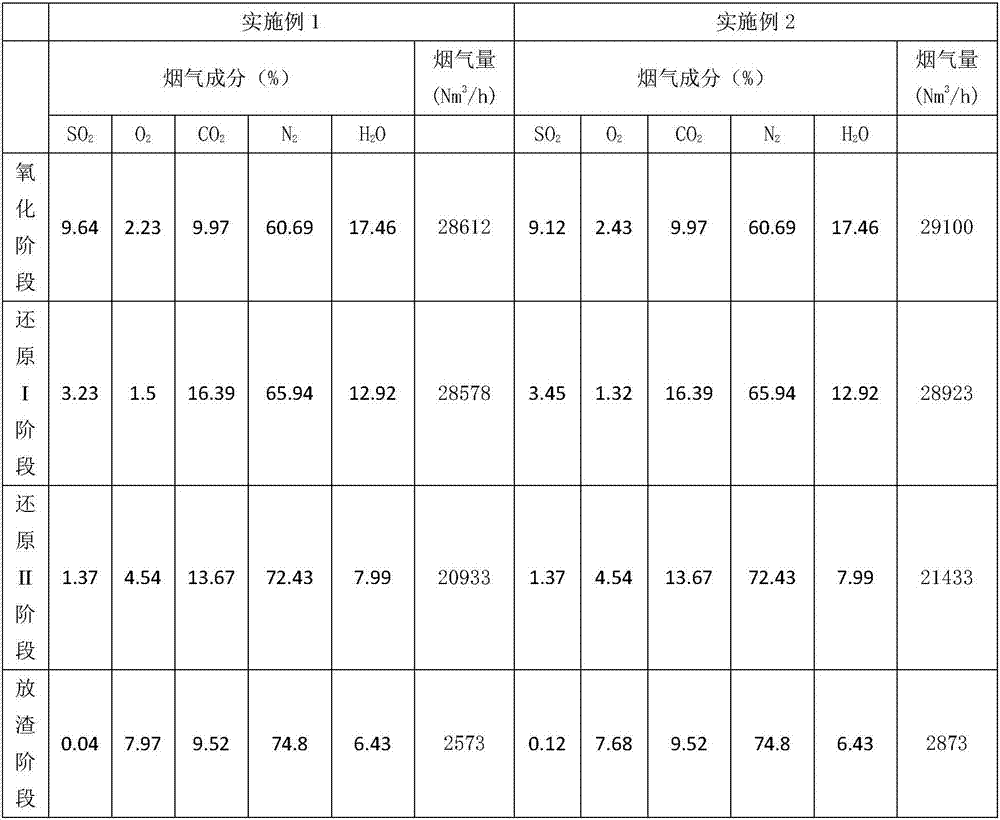

Embodiment 1

[0031] Embodiment 1: a kind of lead concentrate processing technology, it comprises following stages: 1) oxidation smelting stage; 2) reduction smelting I stage; 3) reduction smelting II stage, wherein:

[0032] 1) Oxidation smelting stage: 10-20t / h of lead concentrate with a lead content ≥ 45wt% is mixed with limestone and quartz sand for granulation, and then continuously added to the Ausmelt furnace, and 800-3000Nm of oxygen is injected into the Ausmelt furnace 3 / h, air 7000~15000Nm 3 / h, pulverized coal 0.5-1t / h, maintain oxygen-enriched concentration: 29-31v%, control molten pool temperature 1050-1150°C, carry out oxidation smelting, when the amount of material entering the furnace reaches 180t, and the slag contains 35-42wt% lead , 1) the oxidation smelting stage is completed;

[0033] 2) Stage I of reduction smelting: Add lead concentrate and lump coal into the Ausmelt furnace that has completed 1) oxidation smelting stage, wherein the input amount of lead concentrate ...

Embodiment 2

[0041] Embodiment 2: a kind of lead concentrate processing technology, it comprises the following stages: 1) oxidation smelting stage; 2) reduction smelting I stage; 3) reduction smelting II stage, wherein:

[0042] 1) Oxidation smelting stage: 10-20t / h lead concentrate, lead fume ≤ 10t / h (lead content ≥ 45wt% after mixing) mixed with limestone and quartz sand and granulated continuously into the Ausmelt furnace, then poured into the Ausmelt furnace Spray oxygen 800~3000Nm 3 / h, air 7000~15000Nm 3 / h, pulverized coal 0.5~1t / h, keep the oxygen-enriched concentration: 29~31v%, control the molten pool temperature 1050~1150℃, carry out oxidation smelting, when the amount of material fed into the furnace reaches the rated amount and the lead content in the slag is 35~ 42wt%, 1) the oxidation smelting stage is completed;

[0043] 2) Stage I of reduction smelting: Add lead concentrate and lump coal into the Ausmelt furnace that has completed 1) oxidation smelting stage, wherein the...

Embodiment 3

[0053] Embodiment 3: as figure 1 A kind of lead concentrate treatment process shown, it comprises the following stages: 1) oxidation smelting stage; 2) reduction smelting I stage; 3) reduction smelting II stage, wherein:

[0054] 1) Oxidation smelting stage: Mix and granulate lead-containing materials with a lead content ≥ 45wt% with limestone and quartz sand, then continuously add them into the Ausmelt furnace, and inject 800-3000Nm of oxygen into the Ausmelt furnace 3 / h, air 7000~15000Nm 3 / h, pulverized coal 0.5~1t / h, keep the oxygen-enriched concentration: 29~31v%, control the molten pool temperature 1050~1150℃, carry out oxidation smelting, when the amount of material fed into the furnace reaches the rated amount and the lead content in the slag is 35~ 42wt%, 1) the oxidation smelting stage is completed;

[0055] 2) Stage I of reduction smelting: Add lead concentrate and lump coal into the Ausmelt furnace that has completed 1) oxidation smelting stage, wherein the inpu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| Ash content | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com