Heat-conductive silica gel compound, heat-conductive silica gel material, heat-conductive silica gel slice and preparation method thereof

A technology of heat-conducting silica gel sheet and heat-conducting silica gel, applied in the direction of heat exchange materials, chemical instruments and methods, etc., can solve the problems of reducing heat-conducting silica gel, increasing interaction force, reducing thermal expansion coefficient of heat-conducting silica gel material, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The preparation method of the thermally conductive material provided by the invention comprises the following steps:

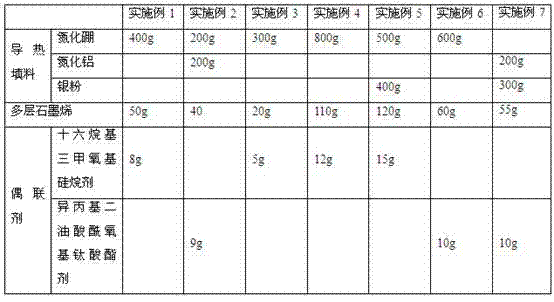

[0025] (1) Add the coupling agent to water or anhydrous ethanol solvent to prepare a coupling agent solution, add thermally conductive filler and multi-layer graphene to the coupling agent solution, stir, suction filter, and dry to obtain the thermally conductive agent material;

[0026] (2) Mix the above-mentioned pretreated thermal conductive agent with silicone resin and other additives, stir at high speed, vacuumize after mixing the materials, and solidify and form.

[0027] In step (1), the mass fraction of the coupling agent solvent is 1.0-2.4wt%. Add thermally conductive fillers and multi-layer graphene at a constant temperature of 60-70°C and continue to stir. After 20-60 minutes of heat preservation, suction filtration after the reaction is sufficient Drying, the drying temperature is 80-110°C.

[0028] The present invention also provides the ...

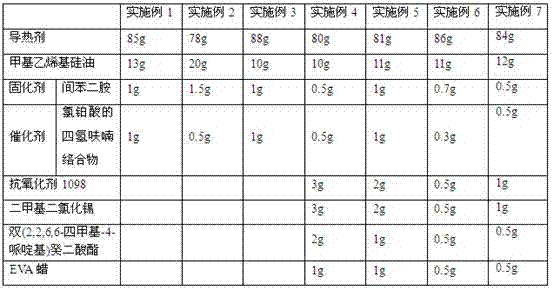

Embodiment 1~7

[0032] This embodiment is used to illustrate the thermally conductive silica gel sheet provided by the present invention and its preparation method.

[0033] (1) Preparation of heat conducting agent

[0034] Prepare 500 g of a silane coupling agent absolute ethanol solution with a concentration of 1.5 wt%, and place it in an oil bath at 65°C. First add a certain amount of multilayer graphene powder, stir at 1000rmp for 10 minutes, then add a certain amount of boron nitride powder and continue stirring for 20 minutes. After the reaction was completed, it was suction filtered, and then dried in a blast drying oven at 110° C. to obtain a heat conducting agent. Refer to the data in Table 1 for the specific group distribution ratio.

[0035] (2) Preparation of thermally conductive silica gel sheet:

[0036] Weigh a certain amount of heat conducting agent prepared in step (1), together with silicone, and at least one of antioxidant, heat stabilizer, light stabilizer, lubricant, etc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com