Preparation method of strain-response conductivehydrogel

A conductive hydrogel and reaction technology, which is applied in the preparation of strain-responsive conductive hydrogel and the preparation of strain-responsive conductive hydrogel synthesized by microwave-assisted heating cooperative assembly, can solve the problems of hydrogel mechanical strength, ductility and toughness , unsatisfactory recoverability and other issues, to achieve good strain response conductivity, reduce production costs, and high fatigue strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

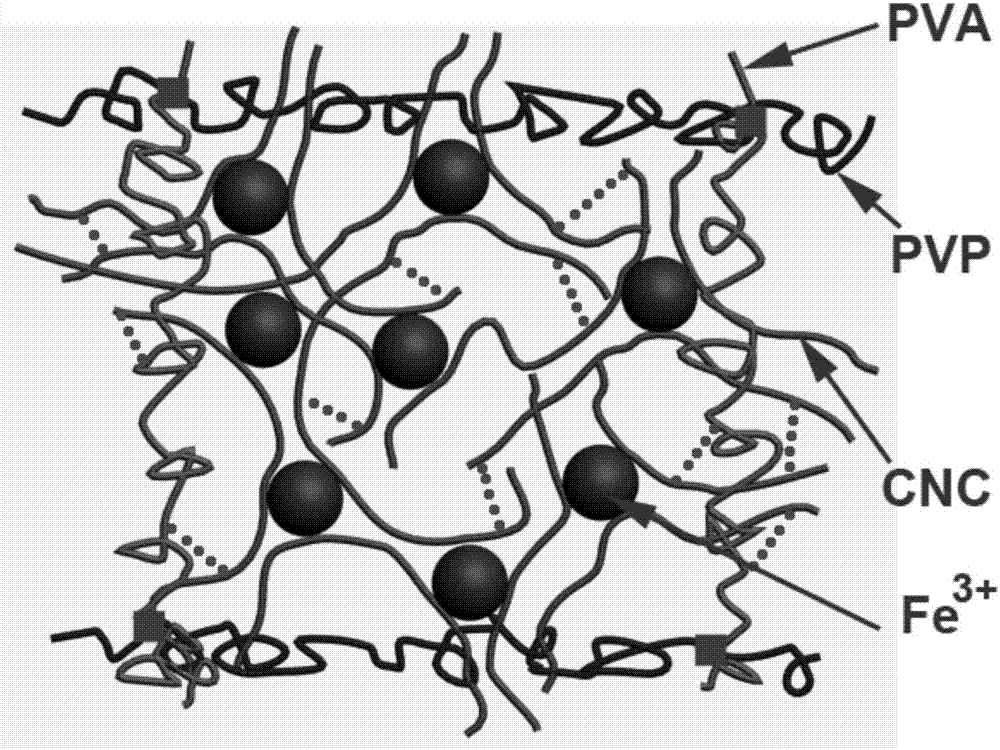

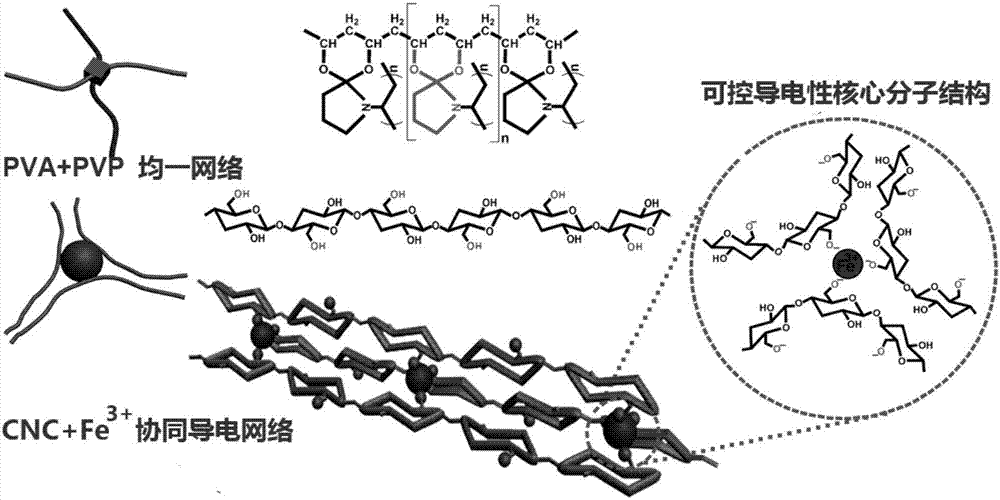

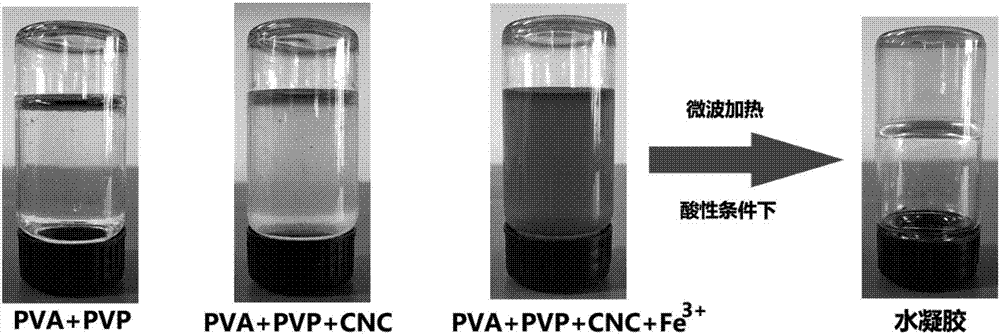

[0042] In the preparation method according to the present invention, the homogeneous network formed by polymer PVA and PVP is used as the matrix phase, and Fe 3+ The "core-skin" structure network formed by coordination with CNC is used as the conductive phase of the hydrogel. First, PVA and PVP are prepared into a solution, then the PVA solution and the PVP solution are mixed in a certain ratio, and then a certain amount of CNC and Fe 3+ , React under microwave-assisted heating conditions, and finally add sulfuric acid dropwise to the reaction solution, stir quickly with a glass rod, and cool to room temperature to obtain a stable hydrogel. This process does not require any complicated experimental equipment and does not add any crosslinking agent , Organic solvents, initiators, and UV-induced conditions, the components are assembled together to form a uniform network structure to give the hydrogel high mechanical strength and high fatigue strength, and it also has strain-respons...

Embodiment 1

[0054] 1) Add 10g of PVA particles (PVA17-88, molecular weight of 170,200,000, alcoholysis of about 88%, Sinopharm Chemical Reagent Co., Ltd.) into 115mL of deionized water, stir magnetically, and heat at 80℃ for 15min , To obtain a PVA solution with a concentration of 8% by mass of polyvinyl alcohol;

[0055] 2) Add 5g of PVP powder (PVP powder K-30, molecular weight 10,000-70,000, Xilong Chemical Co., Ltd.) into 20mL of deionized water and disperse for 15min under ultrasonic conditions to prepare the mass percentage concentration of polyvinylpyrrolidone in the solution 20% PVP solution;

[0056] 3) Preparation of reaction matrix solution

[0057] The polyvinyl alcohol solution obtained in step 1) and the polyvinylpyrrolidone solution obtained in step 2) are mixed and stirred in a volume ratio of 7:3 to obtain a 100 mL solution;

[0058] 4) Preparation of reaction solution

[0059] Preparation of nano cellulose: Take 50 mL of the prepared mass percentage concentration of 58% sulfuric...

experiment Embodiment 1

[0089] Experimental Example 1: Mechanical performance experiment

[0090] A mechanical testing machine (UTM6530) was used to study the mechanical properties of the strain response conductive hydrogel. The sample size used in the tensile test is: 5×2×0.5cm 3 The tensile loading rate is 60mm / min. Such as Figure 5 , 6 As shown, Fe in the hydrogel prepared according to Example 1 3+ The "core-skin" structure formed with nanocellulose can enhance the mechanical properties of the hydrogel. The strain-responsive conductive hydrogel can reach 820% elongation under a tensile stress of 6.2MPa. Under the condition of 80%, the recovery rate of 10 cycles is still maintained at 97.6%, showing super fatigue resistance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| alcoholysis degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com