Aluminum ash utilizing method

A technology of aluminum ash and aluminum ash slag, applied in chemical instruments and methods, ammonia preparation/separation, inorganic chemistry, etc., can solve problems restricting the development of the secondary aluminum industry, and achieve large-scale promotion and application and high utilization efficiency , low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

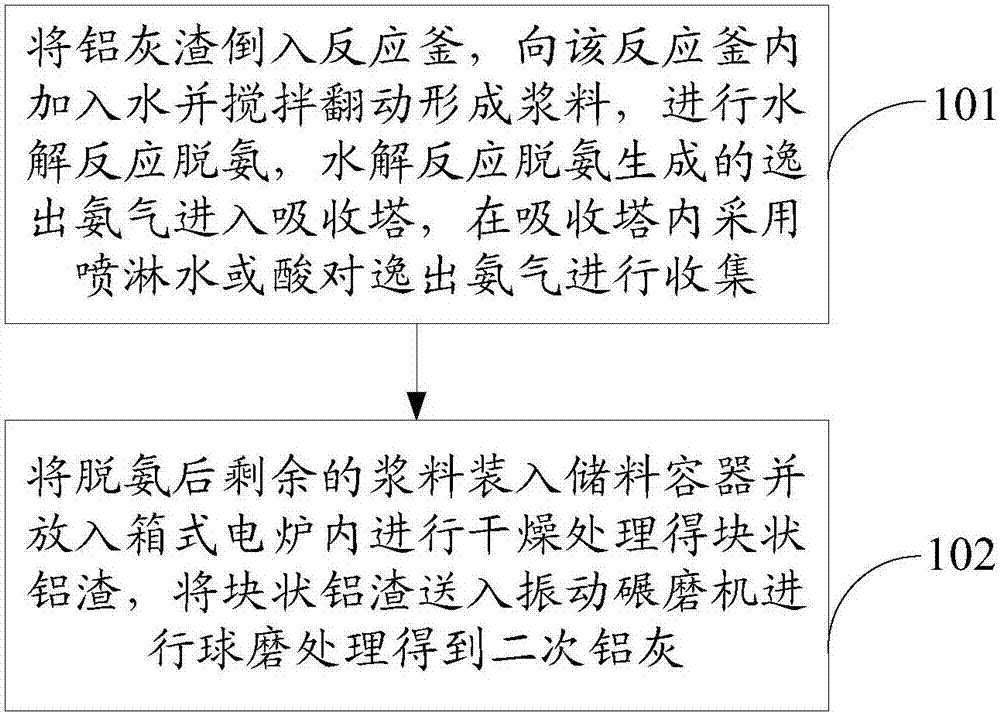

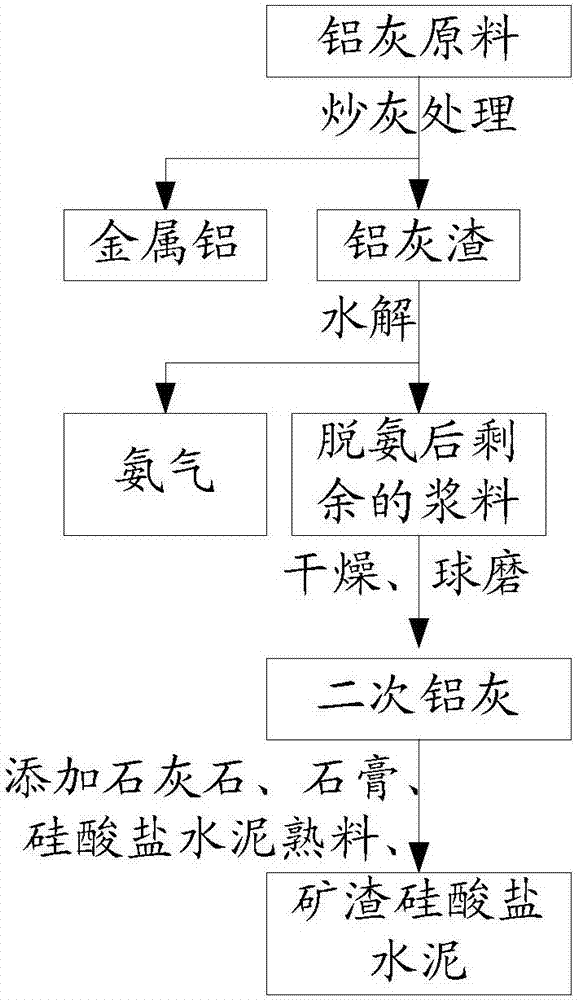

[0053] For example, a method for utilizing aluminum ash includes:

[0054] In a dust-proof environment, the aluminum ash raw material (containing 15.7% alumina, 16.4% elemental aluminum, and 20.5% aluminum nitride) is sent to the ash frying device for frying ash treatment. The temperature of the ash frying is 680 ° C. Metal aluminum in the aluminum ash raw material is extracted to obtain aluminum ash slag;

[0055] Air-cool the aluminum ash to about 80°C and pour it into the reaction kettle, add water to the reaction kettle, the aluminum ash and water are deaminated by hydrolysis at a mass ratio of 1:2, and the prepared ammonia gas is collected by an absorption tower;

[0056] Put the remaining slurry after deamination into a container and put it into a box-type electric furnace for drying treatment to obtain massive aluminum slag, and send the massive aluminum slag to a vibration mill for ball milling to obtain secondary aluminum ash;

[0057] The secondary aluminum ash is t...

Embodiment 2

[0060] For example, a method for utilizing aluminum ash includes:

[0061] In a dust-proof environment, the aluminum ash raw material (containing 7.5% alumina, 23.5% elemental aluminum, and 30.1% aluminum nitride) is sent to the ash frying device for ash frying. Metal aluminum in the aluminum ash raw material is extracted to obtain aluminum ash slag;

[0062] Air-cool the aluminum ash to about 80°C and pour it into the reaction kettle, add water to the reaction kettle, the aluminum ash and water are deaminated by hydrolysis at a mass ratio of 1:3, and the prepared ammonia gas is collected by an absorption tower;

[0063] Put the remaining slurry after deamination into a container and put it into a box-type electric furnace for drying treatment to obtain massive aluminum slag, and send the massive aluminum slag to a vibration mill for ball milling to obtain secondary aluminum ash;

[0064] The secondary aluminum ash is treated as follows: Portland cement clinker, limestone and...

Embodiment 3

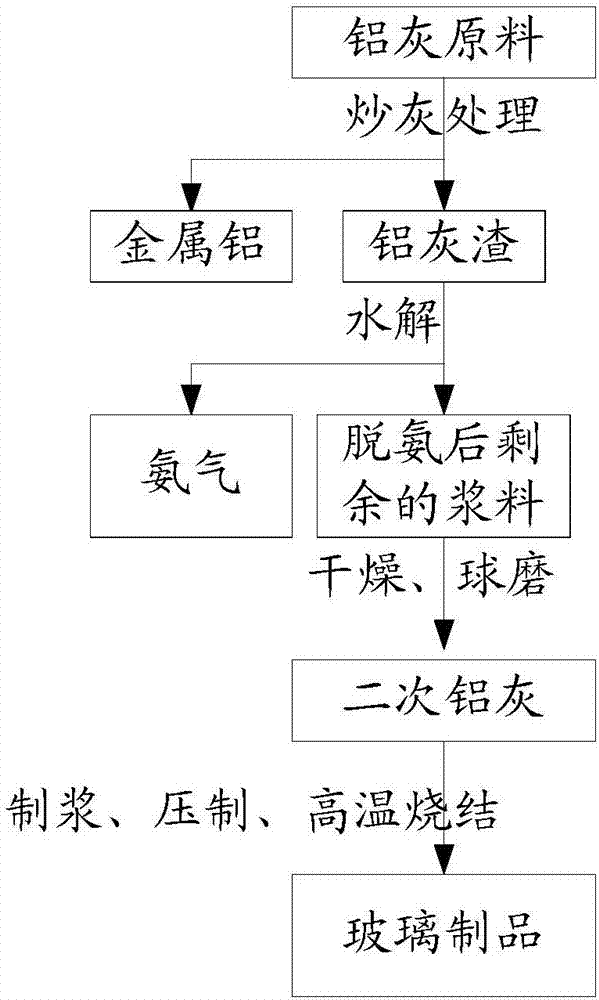

[0067] For example, a method for utilizing aluminum ash includes:

[0068] In a dust-proof environment, the aluminum ash raw material (containing 18.5% alumina, 16.5% elemental aluminum, and 20.4% aluminum nitride) is sent to the ash frying device for ash frying treatment. The ash frying temperature is 700 ° C, and the aluminum ash is extracted Metal aluminum in the raw material is obtained aluminum ash;

[0069] Air-cool the aluminum ash to about 80°C and pour it into the reaction kettle, add water to the reaction kettle, the aluminum ash and water are deaminated by hydrolysis at a mass ratio of 1:2.5, and the prepared ammonia gas is collected by an absorption tower;

[0070] Put the remaining slurry after deamination into a container and put it into a box-type electric furnace for drying treatment to obtain massive aluminum slag, and send the massive aluminum slag to a vibration mill for ball milling to obtain secondary aluminum ash;

[0071] The secondary aluminum ash is t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com