Method based on in situ preparation of target substrates for transferring graphene

A target substrate, in-situ preparation technology, applied in the field of materials science, can solve the problems of reducing the quality of graphene, incomplete structure matching, affecting the conductivity or barrier of graphene, etc., to improve quality, improve conductivity and barrier properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

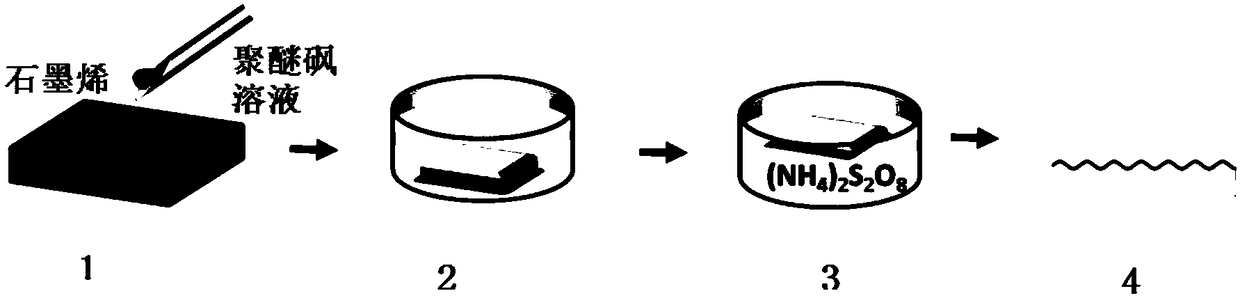

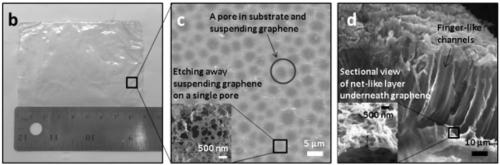

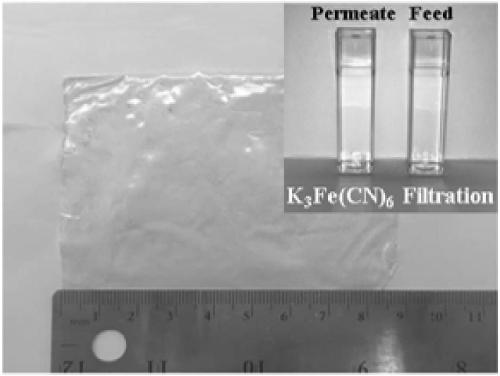

[0044] figure 1 The schematic diagram of the transfer graphene method provided by the invention; figure 1 As shown, (1) uniformly coat CVD graphene on copper with polymer solution; (2) immerse the coated structure in water, causing phase inversion, thereby forming a porous network; (3) by floating the structure in the Ammonium sulfate solution goes up and removes copper; (4) the graphene that finally obtains. That is, the target substrate changes from a liquid phase to a solid phase during the transfer process.

[0045] Specifically, the present invention provides a method for transferring graphene based on in-situ preparation of a target substrate, comprising the following steps:

[0046] S100: Preparing graphene on a solid-phase carrier copper sheet by chemical vapor deposition.

[0047] S101: uniformly coating the target substrate polymer solution on the surface of the graphene deposited on the copper sheet; wherein, the polymer solution is a solution obtained by dissolv...

Embodiment 2

[0052] Image 6 The schematic diagram of the transfer graphene method provided by the invention; Image 6 As shown, the raw material components in the target substrate are transformed from gaseous state to solid state through chemical reaction during the transfer process, for example: the raw material components of the target substrate include the first gas (i.e. Image 6 Component 1) and the second gas (i.e. Image 6 Component 2 in ).

[0053] Specifically, the present invention provides a method for transferring graphene based on in-situ preparation of a target substrate, comprising the following steps:

[0054] S100: Preparing graphene on a solid-phase carrier copper sheet by chemical vapor deposition.

[0055] S101: Put the graphene deposited on the copper sheet into an airtight container, and pass in the first gas; then vacuumize so that only one layer of gas molecules is adsorbed on the surface of the graphene.

[0056] S102: Passing a second gas into the product obt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com