A kind of flake metal powder of sieving-ball milling method and preparation method thereof

A flake metal and metal powder technology, applied in metal processing equipment, transportation and packaging, etc., can solve the problems of accelerated anode sacrificing on zinc surface, unable to form distribution and arrangement, affecting salt spray performance, etc., to reduce trouble and manpower, finished products High rate and good production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

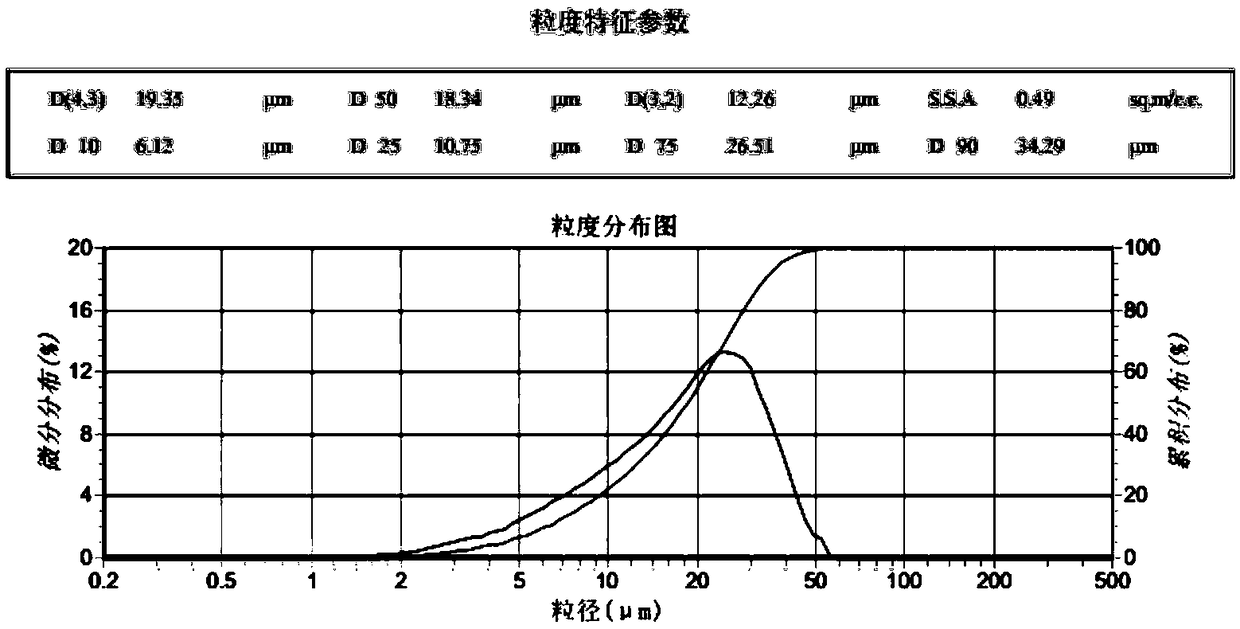

[0046] A flaky zinc powder by sieving-ball milling method, the sheet thickness of the target flaky zinc powder is about 3.3 μm, which is prepared by the following steps:

[0047] Step S1: Sieve the 200-1000-mesh raw zinc powder into zinc powders of different meshes per 50 meshes; the sieving equipment used is a rotary vibrating sieve air classifier or a mechanical vibrating sieve;

[0048] Step S2: Select steel balls with a diameter of 5 mm; put the above-mentioned sieved zinc powder and steel balls into a 100L high-energy ball mill at a mass ratio of 10:1, and metal powder surface coating additives at 1% of the powder mass (the model is Zoz-GmbH), vacuumize, fill with nitrogen, and carry out ball milling in batches; The metal powder surface treatment auxiliary agent is a ternary composite auxiliary agent, and the consumption of the metal powder surface treatment auxiliary agent is the metal powder quality. 1%. Add ternary compound additives to coat the surface of zinc powder...

Embodiment 2

[0066] A flaky zinc powder by sieving-ball milling method, the sheet thickness of the target flaky zinc powder is about 3.0 μm, which is prepared by the following steps:

[0067] (1) Sieve the 200~1000 mesh raw zinc powder into several parts with a mechanical vibrating screen for every 50 mesh;

[0068] (2) Prepare the ternary compound additive that needs to be added to coat the surface of the zinc powder and improve the oxidation resistance of the zinc powder; the amount of the ternary compound additive is 3% of the mass of the metal powder.

[0069] (3) Select a steel ball with a diameter of 5mm;

[0070] (4) Ball milling. Put the above-mentioned sieved zinc powder and steel balls into a 100L high-energy ball mill (model Zoz-GmbH) at a mass ratio of 10:1, and metal powder surface coating additives according to 3% of the powder mass, and vacuumize. Fill with nitrogen, and carry out ball milling according to the batch screened in front;

[0071] (5) The speed of the ball mi...

Embodiment 3

[0081] A flaky zinc powder by sieving-ball milling method, the sheet thickness of the target flaky zinc powder is about 2.8 μm, which is prepared by the following steps:

[0082] 1. Sieve the 200~1000 mesh raw material zinc powder into several parts with a mechanical vibrating screen every 50 mesh;

[0083] 2. Prepare the ternary compound additive that needs to be added to coat the surface of the zinc powder and improve the oxidation resistance of the zinc powder; the amount of the ternary compound additive is 5% of the mass of the metal powder.

[0084] 3. Select a steel ball with a diameter of 5mm;

[0085] 4. Ball milling. Put the above-mentioned sieved zinc powder and steel balls into a 100L high-energy ball mill (model Zoz-GmbH) at a mass ratio of 10:1, and the metal powder surface coating auxiliary agent according to 5% of the powder mass, and vacuumize. Fill with nitrogen, and perform ball milling in batches;

[0086] 5. The speed of the ball mill is 500 rpm, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com