A low-titanium double-layer covering agent for silicon steel and its application method

A technology of covering agent and silicon steel, which is applied in the field of metallurgy, can solve the problems of increasing titanium in molten steel, etc., and achieve the effects of improving the magnetic properties of finished products, reducing thermodynamic conditions, and reducing Ti sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0086] The preparation method of the covering agent includes: mixing the materials of the above-mentioned components according to the weight ratio, and crushing until the average particle size is 1-10mm; or first crushing each material until the average particle size is 1-10mm, and then pressing The weight ratio is mixed evenly.

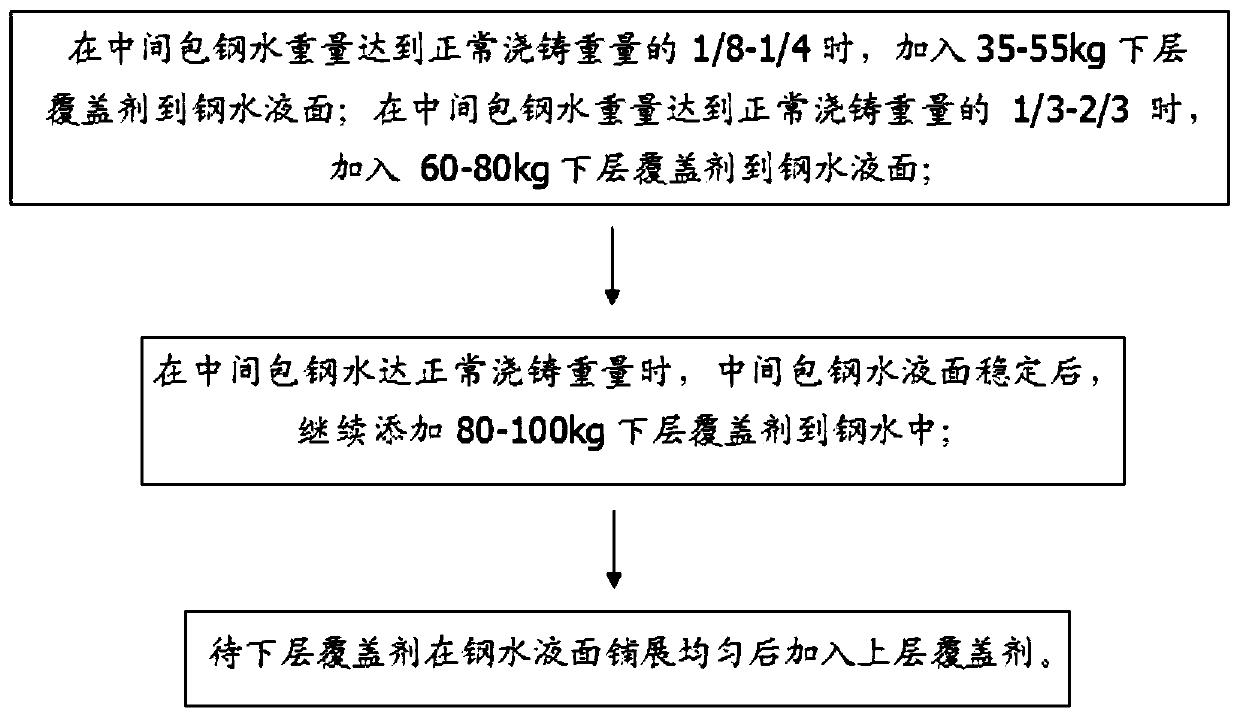

[0087] Such as figure 1 As shown, the embodiment of the present invention is used for the use method of the low-titanium double-layer covering agent of silicon steel, and described method comprises the following steps:

[0088] 1) When the weight of molten steel in the tundish reaches 1 / 8-1 / 4 of the normal casting weight, add 35-55kg of lower layer covering agent to the molten steel surface; when the weight of molten steel in the tundish reaches 1 / 3-2 of the normal casting weight / 3, add 60-80kg of lower layer covering agent to the molten steel surface;

[0089] 2) When the molten steel in the tundish reaches the normal casting weight, after the li...

Embodiment 1

[0094] Embodiment 1 of the present invention is a special low-titanium double-layer covering agent for high-grade silicon steel, including an upper layer covering agent and a lower layer covering agent, wherein the chemical composition and weight percentage of the upper layer covering agent are: SiO 2 45%, MgO 5%, CaO6%, Fe 2 o 3 4%, Al 2 o 3 22%, C (full) 0.4%, TiO 2 ≤0.2%, the remainder is loss on ignition; the chemical composition and weight percentage of the lower covering agent are: SiO 2 16%, MgO 5%, CaO 56%, Fe 2 o 3 4%, Al 2 o 3 0.6%, C (full) 0.4%, TiO 2 0.12%, the balance is loss on ignition.

[0095] Embodiment 1 of the present invention is used for the use method of the low-titanium double-layer covering agent of silicon steel, and described method comprises the steps:

[0096] 1) When the weight of the molten steel in the tundish is 1 / 6, add the lower covering agent, add 25kg of the lower covering agent to the temperature measurement sampling holes ...

Embodiment 2

[0102] Embodiment 2 of the present invention is a special low-titanium double-layer covering agent for high-grade silicon steel, including an upper layer covering agent and a lower layer covering agent, wherein the chemical composition and weight percentage of the upper layer covering agent are: SiO 2 53%, MgO 7%, CaO7%, Fe 2 o 3 4%, Al 2 o 3 30%, C (full) 0.7%, TiO 2 0.34%, the balance is loss on ignition; the chemical composition and weight percentage of the lower layer covering agent are: SiO 2 21%, MgO 6%, CaO 61%, Fe 2 o 3 7%, Al 2 o 3 0.6%, C (full) 0.6%, TiO 2 0.08%, the balance is loss on ignition.

[0103] Embodiment 2 of the present invention is used for the use method of the low-titanium double-layer covering agent of silicon steel, and described method comprises the following steps:

[0104] 1) When the weight of the molten steel in the tundish is 1 / 8, start to add the lower layer covering agent, add 20kg of the lower layer covering agent to the tem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com